2

Parker Hannifin Corporation

Bulletin TI-HFX-3D

Description

Prefiltration

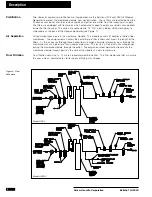

Two stages of coalescing prefiltration are incorporated into the Balston HFX-3 and HFX0-3 Nitrogen

Generator to protect the membrane module from contamination. These filters are located behind the

filtration access panel, and they remove liquids and particulate matter from the incoming air supply.

The filters are equipped with float drains which automatically open to empty any liquids accumulated

inside the filter housing. The drains are connected to 1/4" O.D. plastic tubing which discharges to

atmosphere at the back of the nitrogen generator (see Figure 1).

Air separation takes place in the membrane module. This module consists of bundles of hollow fiber

membranes. The compressed air enters the center bore of these fibers and travels the length of the

fibers. As the air passes through these hollow fibers, oxygen and water molecules pass through the

membrane wall at a higher rate than nitrogen molecules. The result is a high purity, dry nitrogen gas

exiting the membrane module through the outlet. The oxygen enriched permeate stream exits the

membrane module through ports on the side of the module at a very low pressure.

Final filtration consists of a .01 micron (absolute) membrane filter. The final membrane filter will assure

the user a clean, commercially sterile supply of high purity nitrogen.

Air Separation

Final Filtration

Figure 2 - Flow

Schematic

Model HFX-3

Model HFX0-3