Bulletin HY14-1450-M1/US

Bul 1450-M1pgs.p65, dd

Flow Control Servovalves

8

Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Contamination Resistant

Electrohydraulic Servovalves

The Parker BD series servovalves are ruggedly

designed for use in the industrial market place. From

its inception, the first stage amplifier (pilot valve) has

established a solid history of trouble-free operation in

very harsh environments. Minimum orifice diameters

up to 20 times larger than other servovalve models

substantially increase reliability by reducing problems

due to contamination. The second stage is a closed

center, four-way spool and sleeve assembly which

features rectangular slots in the sleeve. The spool

metering edges exactly match the flow slot edges in

the sleeve to provide linear flow with respect to electri-

cal input. The valves have rated flows up to 40 GPM.

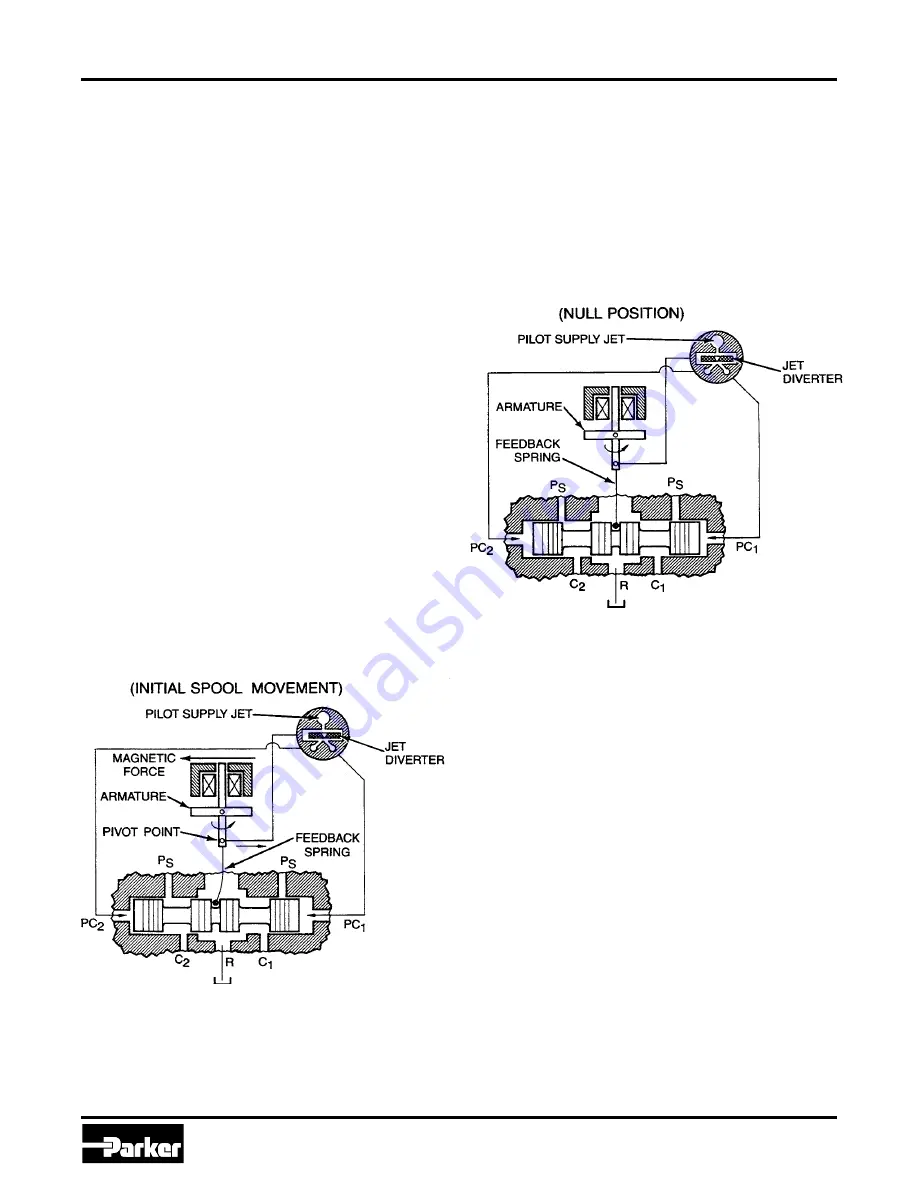

Operation

The BD series servovalves operate on a force feed-

back principle between the second stage spool meter-

ing valve and the first stage pilot valve torque motor.

The pilot valve is a single jet pressure recovery unit

that directs a continuing stream of control fluid into a

receiver. The receiver has two outlets that are ported

to the ends of the valve main spool, PC1, and PC2.

The pressure in these ports is equal when the fluid jet

is centered in the receiver opening.

The feedback spring attached to the armature mea-

sures spool position as a force. This force and the

force of the torque motor armature provide the error

displacement of the armature and its diverter blade

window. The window edges divert the jet stream to the

proper receiver outlet to position the spool to the

electrically commanded position.

Figure 2. Servovalve Operation - Command for Flow from Control

Port C2

An electrical signal applied to the pilot valve coil

generates a magnetic force on the armature/diverter

blade assembly, pivoting the assembly and allowing

fluid to flow into PC1. See Figure 2. This positions the

main power spool to the left until the force from the

feedback spring matches the magnetic force. At this

time the diverter blade is re-centered over the receiv-

ing orifices, and the spool motion stops at this position.

Flow, proportional to the input electrical current, is then

metered out the C2 port. Removal of the electrical

signal to the coil unbalances the forces, which re-

verses the armature deflection and drives the spool to

the zero current or null position, as shown in Figure 3.

Changing the polarity of the current to the coil causes

a magnetic force in the opposite direction that results

in flow from the C1 port.

Figure 3. Servovalve Operation - Null Position, Valve in Balance

Servovalve Installation

For maximum valve and system component life, the

hydraulic system should be flushed and filtered to an

absolute filtration of 25 µm before installing the

servovalve. A flushing valve should be used in place of

the servovalve while cleaning the system. These

valves are available from Hydraulic Valve Division, as

follows:

BD15 flushing valve - PN 1200127

BD30 flushing valve - PN 1200128

To keep contaminants from entering the servovalve

and/or hydraulic system, keep the valve shipping cover

in place until immediately prior to installation. Never

leave the port surfaces uncovered and exposed to

contamination. A permanent non-bypass filter should

be installed in the system to assure that the valve

receives a clean supply of oil.

The valve should be mounted as close as possible to

the actuator or motor. It can be mounted in any plane,

but it is best to have the spool as nearly horizontal as

possible.

The servovalve should be set up for the system

operating pressure according to the instructions in the

Operating Pressure

portion of the

Servovalve

Maintenance

section.

Installation Information

Series BD15 and BD30