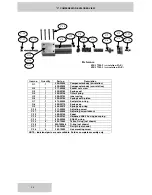

"RN" VENTED COMPENSATOR

22

Item no.

Quantity

Part no.

Description

03E-93694

Compensator body (cw rotation) [SEE NOTE 2]

RN-1

1

03E-93688

Compensator body (ccw rotation) [SEE NOTE 2]

RN-2

1

03E-93165

Spring seat

RN-3

1

03E-94203

Bias spring

RN-4

1

03E-94202

Spring seat & piston

RN-5

1

675-00009

Seal piston o-ring

RN-6

1

618-15022

Seal piston back-up ring

RN-7

1

03E-94227

Spring cap

RN-8

1

695-00912

Spring cap o-ring

RN-9

1

311-50003

Adjusting screw

RN-10

1

340-00056

Adjusting screw locknut

RN-11

1

03E-93156

Spool

RN-12

1

03E-93163

Hardened SAE #2 o-ring boss plug

RN-13

1

695-00902

SAE #2 o-ring

RN-14

4

SEE NOTE 3

Hex mounting screw

RN-15

3

03E-93270

Orifice plug (1 not shown)

RN-16

1

311-50006

Socket set screw

RN-17

4

605-10069

Teflon O-ring (not shown)

RN-18

1

325-36002

Roll pin (not shown)

NOTE 1

Individual parts are not available. Sold as complete assembly only.

NOTE 2

D03 Mount on top of body.

NOTE 3

Dependent on top valve.

RN-13

RN-11

RN-2

RN-8

RN-7

RN-

12

RN-4

RN-3

RN-5

RN-6

RN-1

RN-10

RN-9

RN-15

RN-16

RN-14

Reference:

S2E 17958-5 (cw rotation, SAE)

S2E 17924-5 (ccw rotation, SAE)

Summary of Contents for COMPAX P1 Series

Page 5: ...SAE FLANGE DIMENSIONS 5...

Page 6: ...SAE FLANGE DIMENSIONS 6...

Page 7: ...SAE FLANGE DIMENSIONS 7...