Parker Hannifin Corporation

Hydraulic Pump and

Power Systems Division

Marysville, Ohio USA

Bulletin HY28-2665-02/SVC/EN

Medium Pressure Axial Piston Pumps

P1/PD Maintenance

47

6.

Carefully remove the port block. Use caution to avoid dropping the port

plate. Note the location of the bias spring - piston assembly and the control

piston assembly. The control piston, bias piston and bias spring may remain

in pump when port block is removed. Remove and discard the three white

Teflon seals on the port block. These seals should be replaced each time the

pump is disassembled.

7.

Remove the control piston and the bias piston - spring assembly.

NOTE:

For rotation change only do not disassemble further, proceed to step 16.

8.

Remove the tapered roller bearing cone and shim from the end of the shaft.

9.

Position the pump horizontally and remove the rotating group. Avoid sepa-

rating the pistons from the barrel if possible. This will assist in identifying

damage between an individual piston and bore during component inspection.

10. Remove the drive shaft.

NOTE : For shaft change only, no further disassembly is required. Pro-

ceed to assembly procedure step 5.

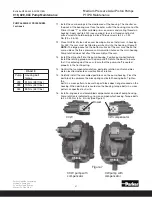

11. Remove the cam by rotating it 90 degrees and carefully extracting it from

the pump housing. Note the large pocket under the cam fits on the pressure

control side of the pump housing (same side as the three seals on the hous-

ing flange). Figure 2

12. Remove the front tapered roller bearing cone.

13. If there is excessive wear or damage, remove the tapered roller bearing cup

from the bottom of the housing.

14. If completing a seal change or complete overhaul, turn the housing over and

remove the snap ring and shaft seal from the housing. Note: do not reuse the

shaft seal.

15. If there is excessive wear on the port block bearing cup, cone, or both; re-

move the tapered roller bearing cup from the port block.

16. If complete overhaul or rotation change, remove control piston and bias

piston guides. The control piston and bias piston guides are installed with

anerobic thread lock. Place the port block wih piston guides in oven at 163°

C (325° F)

NOTE: To prevent annealing of heat treated surfaces: DO NOT USE A

TORCH TO HEAT PISTON GUIDES.

Large Pocket

Pressure control

side of pump

060, 075, 100, 140 Pump Maintenance

PUMP DISASSEMBLY PROCEDURE

(continued)