7

OEM650/OEM650X • INSTALLATION

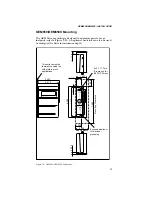

OEM size 34 motors are internally wired in parallel.

A 75VDC

power supply (OEM300) must be used to achieve maximum perfor-

mance;

however, lower voltage power supplies may be used (less

than 75VDC but must be greater than 24VDC). The lower voltage

power supply will not adversely affect the system's low-speed

performance, but it will not yield the optimum high-speed perfor-

mance achieved by using the 75VDC power supply.

❐

Size 34 motors are internally wired in a parallel configuration

(OEM83-62-MO, OEM83-93-MO, OEM83-135-MO)

Top View

BLACK

A-

GREEN

B-

RED

A+

WHITE

B+

OEM

s

e

r

i

e

s

REMOTE

REF

CURRENT

DUMP

VDC+

VDC-

A+

A-

B+

B-

POWER

FAULT

}

Size 34 OEM Series Motors: Parallel Wiring

Figure 2-3. NEMA 34 Size OEM Motor Wiring—Series

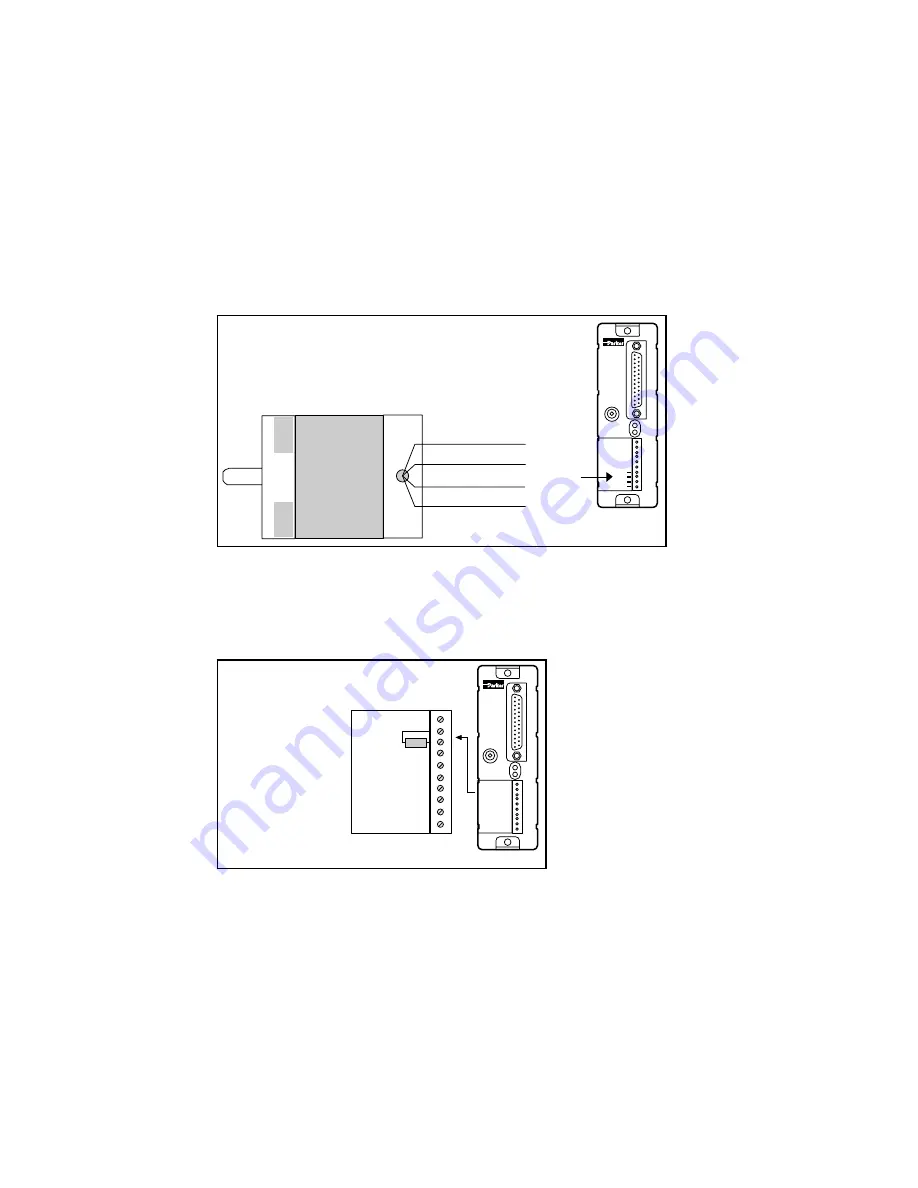

5. Set motor current. Table 2-7 contains the proper motor current

settings for Compumotor OEM motors. A 1/4 watt resistor

connected between

REF

and

CURRENT

sets

motor current

.

Adjust the drive current to match the motor that you are using.

OEM

s

e

r

i

e

s

REMOTE

REF

CURRENT

DUMP

VDC+

VDC-

A+

A-

B+

B-

POWER

FAULT

REMOTE

REF

CURRENT

DUMP

VDC+

VDC-

A+

A-

B+

B-

Motor Current

Selection Resistor

OEM650/OEM650X

Terminals

For best installation

results, be sure that the

resistor lead wire is long

enough for easy insertion

into the REF and

CURRENT terminals.

Figure 2-4. Motor Current Selection Resistor