INSTALLATION • OEM650/OEM650X

22

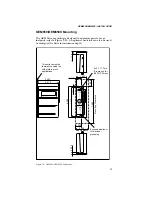

Motor Mounting

Rotary stepper motors should be mounted with flange bolts and

positioned with the centering flange on the front face. Foot-mount or

cradle configurations are not recommended because the motor's

torque is not evenly distributed around the motor case and they offer

poor registration. Any radial load on the motor shaft is multiplied by

a much longer lever arm when a foot mount is used rather than a

face flange.

WARNING

Improper mounting can reduce system performance & jeopardize personal safety.

The motors used with the OEM650/OEM650X can produce very

large torques. These motors can also produce high accelerations.

This combination can shear shafts and mounting hardware if the

mounting is not adequate. High accelerations can produce shocks

and vibrations that require much heavier hardware than would be

expected for static loads of the same magnitude. The motor, under

certain profiles, can produce low-frequency vibrations in the mount-

ing structure. These vibrations can cause metal fatigue in structural

members if harmonic resonances are induced by the move profiles

you are using. A mechanical engineer should check the machine

design to ensure that the mounting structure is adequate.

CAUTION

Consult a Compumotor Applications Engineer [800-358-9070] before you machine the

motor shaft. Improper shaft machining can destroy the motor’s bearings.

Never

disassemble the motor (it will cause a significant loss of torque).

Attaching the Load

This section discusses the main factors involved when attaching the

load to the motor. The following three types of misalignments can

exist in any combination.

Parallel Misalignment

The offset of two mating shaft center lines, although the center lines

remain parallel to each other.

Angular Misalignment

When two shaft center lines intersect at an angle other than zero

degrees.

End Float

A change in the relative distance between the ends of two shafts.