General Product Philosophy

The ZETA6xxx was not designed originally for EMC compliance. Therefore, it will require specific measures to be

taken during installation. The ultimate responsibility for ensuring that the EMC requirements are met rests with the

systems builder.

It is important to remember that for specific installations, the full protection requirements of the EMC Directive

89/336/EEC need to be met before the system is put into service. This must be verified either by inspection or by

testing. The following EMC installation instructions are intended to assist in ensuring that the requirements of the

EMC directive are met. It may be necessary to take additional measures in certain circumstances and at specific

locations.

It should be stressed that although these recommendations are based on expertise acquired during tests carried out on

the ZETA6xxx, it is impossible for Compumotor to guarantee the compliance of any particular installation. This will

be strongly influenced by the physical and electrical details of the installation and the performance of other system

components. Nevertheless, it is important to follow all the installation instructions if an adequate level of compliance

is to be achieved.

Safety Considerations

The ZETA6xxx is intended for installation according to

the appropriate safety procedures including those laid

down by the local supply authority regulations. The

recommendations provided are based on the requirements

of the Low Voltage Directive and specifically on

EN60204. It should be remembered that safety must never

be compromised for the purpose of achieving EMC

compliance. Therefore in the event of a conflict occurring

between the safety regulations and the following

recommendations, the safety regulations always take

precedence.

Ferrite Absorbers and P-Clips

Ferrite Absorber Specifications

The absorbers described in these installation

recommendations are made from a low-grade ferrite

material which has high losses at radio frequencies. They

therefore act like a high impedance in this waveband.

The recommended components are produced by Parker

Chomerics (617-935-4850) and are suitable for use with

cable having an outside diameter up to 10-13mm. The

specification is as follows:

Chomerics part #

83-10-M248-1000

83-10-A637-1000

Outside diameter

17.5mm

28.5mm

Inside diameter

10.7mm

13.77mm

Length

28.5mm

28.57mm

Impedance at 25MHz

80

Ω

135

Ω

Impedance at 100MHz

120

Ω

210

Ω

Curie temperature

130°C

130°C

(the device should not be operated near this temperature)

Handling & Installing Ferrite Absorbers

Take care when handling the absorbers—they can shatter

if dropped on a hard surface. For this reason the suggested

method of installation is to use a short length of 19mm

diameter heat-shrink sleeving (see Figure 1). This gives a

degree of physical protection while the cable is being

installed. The sleeving should have a shrink ratio of at

least 2.5:1. Cable ties may be used as an alternative,

however they give no physical protection to the absorber.

Figure 1. Ferrite Sleeve Installation

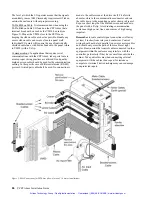

P-Clip Installation Details

The function of the P-clip is to provide a 360-degree

metallic contact and thus a convenient means of ensuring a

proper R.F. ground. When dealing with EMI issues, it is

important to remember that continuity, a DC connection,

does not at all speak to the integrity of an AC (high-

frequency) connection. High-Frequency bonding typically

involves wide, flat cabling to establish a suitable system

Appendix D

E M C I n s t a l l a t i o n G u i d e l i n e s

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com