Index

71

3rd harmonic 32

4-lead motor (non-Compumotor) wiring

57

6-lead motor (non-Compumotor) wiring

57

5V power supply

connections (see page for

connection item, like P-CUT,

Encoder, etc.)

load limit 5

8-lead motor (non-Compumotor) wiring

58

A

AC input power connections & specs

25

acceleration range 4

accuracy

stepping 4

velocity 4

active damping

configuration procedure 36

definition 55

active levels (see polarity)

ADDR (auto addressing) command 7

address

auto-address multiple units 7

DIP switch selection 7

air-flow space, minimum 9

airborne contaminants 9

anti-resonance

configuring 36

definition 55

gain 55

phase 55

assumptions (skills & knowledge

required for installation) i

auto addressing multiple units 7

auto baud procedure 7

auto current standby 13, 35

B

balance 30

battery, changing 62

baud rate 4

automatic selection 7

BBS (bulletin board service) 46

BCD input via thumbwheels 24

bearings, zeta & OS/RS motors 5

bias resistors

calculating 12

DIP switch selection 8

bipolar current 59

C

cables

I/O, extending 26

motor 13

serial communication (max. length)

50

calculating bias & termination resistors

12

change summary i

circuit drawings (see back cover of

manual, and “schematics, internal”)

COM 2 port function 8

common problems & solutions 48

communication

Motion Architect 42

serial (see serial communication)

terminal emulation 27

troubleshooting 50

conduit 3, 26

configuration

active damping 36

address 7

anti-resonance 36

autobaud 7

bias resistor selection 8

COM 2 port function 8

electronic viscosity 38

matching the ZETA6xxx to the

motor 30

motor current 7

recording 40

RS-485 setup 8

serial communication on COM 2 8

termination resistor selection 8

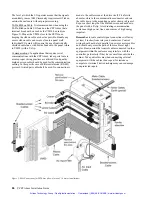

connections

computer 12, 27

daisy-chain 12

EMC-compliance guidelines 63

encoder 18

end-of-travel limit inputs 17

grounding 11

home limit inputs 17

lengthening cables 26

LVD-compliant installation 61

motor 13

non-Compumotor 58, 59

wiring options 14-16

multi-drop 12

PLC inputs 22, 23

PLC outputs 21

power (VAC) input 25

programmable inputs 21

programmable outputs 23

pulse cut-off input (P-CUT)11

RP240 25

RS-232C 12

RS-485 12

terminal 12, 27

testing 27, 28

thumbwheels 24

trigger inputs 19

VM50 screw terminal adaptor 20

contaminants 10

cooling the motor 35

coupling the motor to the load 35

current, motor

bipolar rating 59

selecting 7

non-Compumotor motors 59

unipolar rating 59

waveform 32

current loop gain 55

D

DACTDP (active damping) command

40

daisy-chain connections 12

damping

configuration

active damping 36

anti-resonance 36

electronic viscosity 38

defined 54

DAREN (anti-resonance) command 54

part of set-up program 41

DAUTOS command

part of set-up program 41

DDE6000™ 43

DELVIS (electronic viscosity)

command 39

part of set-up program 40

device address (see address)

diagnostic LEDs 46

dimensions

motor 33

ZETA6xxx 9

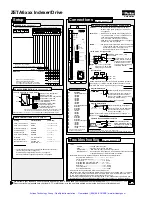

DIP switch settings

address 7

autobaud feature 7

bias & termination resistors 8

motor current 7

disassembling the ZETA6xxx 8

DMTIND (inductance) command

part of setup program 41

DMTSTT (static torque) command

part of set-up program 41

drive resolution 48

drive/motor matching 30

DRPCHK command 25

part of set-up program 40

I N D E X

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com