HY28-2668-01/GC/NA,EU

GOLD CUP

®

Series - Application Manual

Piston Pumps & Motors

4.2

Parker Hannifin Corporation

Hydraulic Pump Division

Marysville, Ohio USA

Section 4

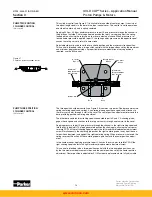

When pressure sources are used to control the PCOR, the isolation checks will have to be re-

versed. (See Figure 4.3). Under these conditions it may be necessary to install bleed orifices

to insure the pressure in the line between the isolation check and PCOR vent port will drop

off when the pressure source does. Flows from pressure sources must be limited to prevent

overpowering the PCOR pilot section if it must take over control.

In hydraulic circuits where multiple functions are driven from a single pump, it has been com-

mon practice to use a fixed displacement pump and open center valves. In these circuits, the

control valves throttle flow and pressure into the load circuit, where the actuator operates at

the speed commanded by the opening of the valve and the pressure required by the load.

Since the pump is a fixed displacement pump, excess flow must be bypassed through a

system relief valve to the reservoir. This relief valve must be set to the highest required pres-

sure in order for the machine to operate satisfactorily. The pump must be sized to produce

adequate flow so the machine will operate at its designed speed when many functions are

simultaneously engaged.

The fixed displacement pump operating at a fixed pressure uses maximum horsepower all the

time the functions are engaged and, therefore, the machine is very inefficient during periods

of light load or when few functions are being used.

To reduce these horsepower losses and high heat loads the concept of load sensing has

been devised. Load sensing means that the pump output pressure will be set to the highest

pressure required in the circuit at that instant in order to reduce the horsepower used. When

used in conjunction with the pressure compensator override of the GOLD CUP

®

transmission

pumps, load sensing not only reduces the output pressure of the pump to the highest required

pressure, but also allows the pump to deliver only the flow required at that moment by the cir-

cuit. This offers additional horsepower savings over the system that operates on pressure only.

The diagram in Figure 4.4 shows a variable volume GOLD CUP

®

pump with a modified (no

orifice in sequence poppet) pressure compensator override providing to two separate load

functions through proportional flow control 4-way valves. To load sense a GOLD CUP

®

pump,

it is necessary to connect the vent port of the pressure compensator override to the shuttle

valve logic, which insures that the highest pressure is available to the output of the logic. This

logic circuit is shown in the enclosed diagram as four shuttle valves. Each valve has one end

connected to the individual system lines, while the other ends are tied together to the vent

port. Installing the shuttle valves with the free flow direction leading from the system to the

vent port insures that the highest pressure system leg is connected to the vent port. All other

valves will be shut off by this higher pressure.

Figure 4.3

Remote control of PCOR by pressure

sources

LOAD SENSING

Figure 4.4

Load sensing

FLOW LIMITING ORIFICE

BLEED ORIFICE

ISOLATION

CHECK

VALVES

TO PRESSURE

SOURCES

p

.047, 1mm ORIFICE

www.comoso.com