12

DUSTHOG PNP Series

3.4.1 Electrical Supply Power

The main power supply is connected to the PNP unit through a 1˝ FNPT coupling located on the rear

of the unit shown in Figure 1B. After feeding wires through the coupling, terminations are made on

the main bus bar terminal for each phase and frame ground connection. The rear electrical panel also

contains the unit circuit breakers and DC power supply for the controls components. Utilize Table 1

for wire, fuse and disconnect sizing for your respective product model. A second plugged 1˝ FNPT

coupling is also located on the rear of the cabinet for low optional voltage connections using the

process control feature to automate operation. Ensure that the rear electrical panel cover is in place

and secured prior to operating the unit. Refer to the electrical wiring diagrams in Table 2 for additional

wiring information.

Note:

When making the main power connections to the unit, fan rotation check is not required.

The blower will automatically turn in the correct direction.

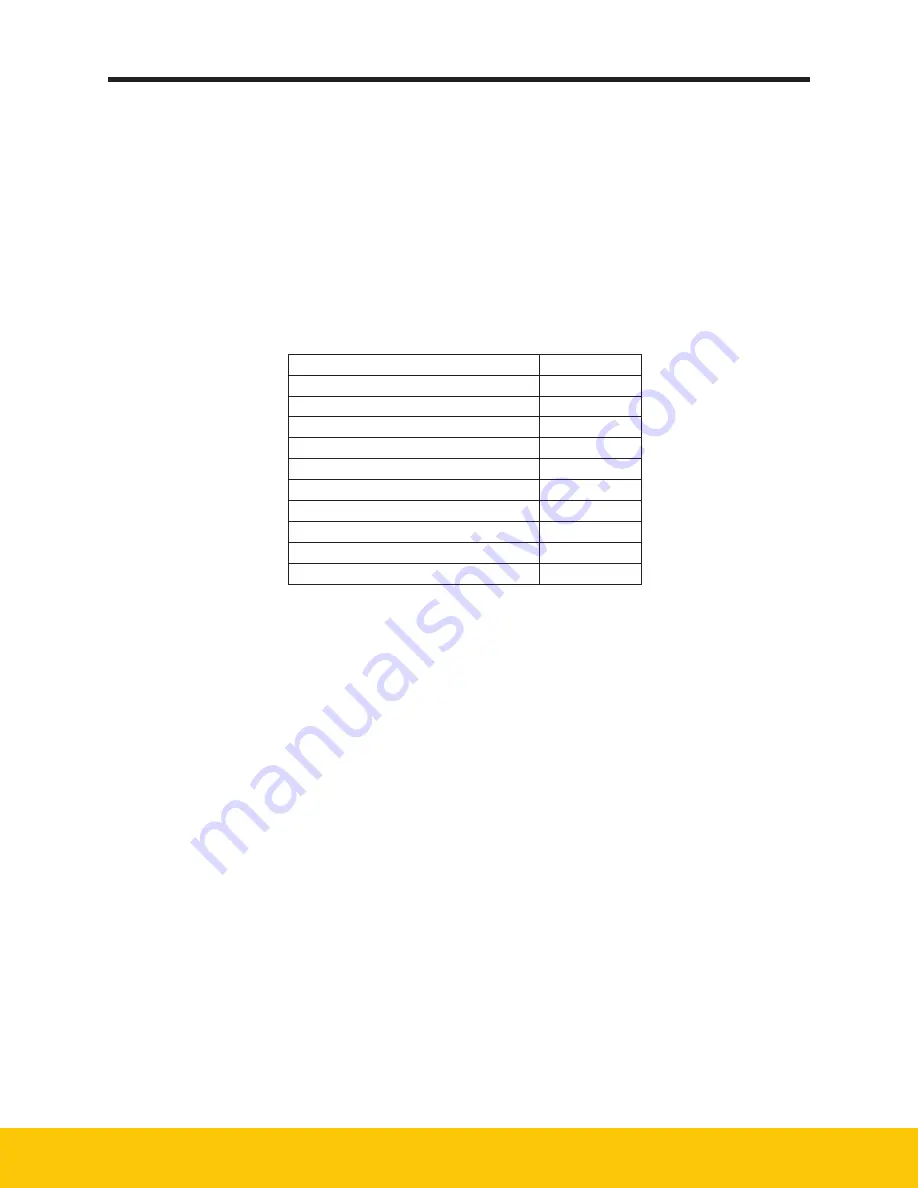

Descripon of Wire Diagram

Appendix

Transformer 575:480

A1

One Blower & Controls

A2

Two Blower & Controls

A3

Three Blower & Controls

A4

Four Blower & Controls

A5

Remote Panel Controls

A6

One Blower & Remote Controls

A7

Two Blower & Remote Controls

A8

Three Blower & Remote Controls

A9

Four Blower & Remote Controls

A10

TABLE 2

Wire Diagrams

3.4.2 Electrical Touchscreen Controls

The main control panel for the PNP unit is a touchscreen interface located integrally on the front of

the unit or remotely in an auxiliary enclosure (refer to section 3.4.3) that operates the blower and filter

pulse cleaning system. Both the touchscreen control panel and filter pulse cleaning valves are powered

by 24V DC. Refer to Section 4 of this manual for operation of the touchscreen. All wiring in the

touchscreen controls panel is pre-wired at the factory and there are no customer connections at this

panel. The panel door should remain closed and locked during operation.

3.4.3 Remote Controls Panel

The PNP unit is available with a remote controls panel that allows touchscreen controls to be located

within 100 ft. (30.5 m) from the PNP unit location. The controls are provided in a NEMA 4X enclosure

for mounting. The remote display panel will come pre-wired with two cables, one is the 24 VDC power

supply, along with control cables and the other is a communications cable that must be connected

to the PNP unit upon installation. Note that these wires are low voltage and should not be run next to

high voltage wires. These wires should be cut to final length at installation.

Summary of Contents for DUSTHOG PNP

Page 1: ...DUSTHOG Plug Play Fume Dust Collector Owner s Manual Model PNP...

Page 6: ...Page intentionally left blank...

Page 11: ...7 DUSTHOG PNP Series 61 10121 Figure 2 PNP Weights and Lifting Info...

Page 27: ...23 DUSTHOG PNP Series Page intentionally left blank...

Page 29: ...25 DUSTHOG PNP Series PNP 12 Figure 24 PNP Replacement Parts 61 10123...

Page 30: ...26 DUSTHOG PNP Series A1 Transformer 575 480 8 Appendix Wiring Diagrams 04 001886...

Page 31: ...27 DUSTHOG PNP Series A2 One Blower Controls 04 001830...

Page 32: ...28 DUSTHOG PNP Series A3 Two Blower Controls 04 001831...

Page 33: ...29 DUSTHOG PNP Series A4 Three Blower Controls 04 001832...

Page 34: ...30 DUSTHOG PNP Series A5 Four Blower Controls 04 001881...

Page 35: ...31 DUSTHOG PNP Series A6 Remote Panel Controls 04 001868...

Page 36: ...32 DUSTHOG PNP Series A7 One Blower Remote Controls 04 001833 A7...

Page 37: ...33 DUSTHOG PNP Series A8 A8 Two Blower Remote Controls 04 001834...

Page 38: ...34 DUSTHOG PNP Series A9 Three Blower Remote Controls 04 001863...

Page 39: ...35 DUSTHOG PNP Series A10 Four Blower Remote Controls 04 001864...