Axial Piston Pumps

Series eP2 / eP3 – Electronic Controls

5

Parker Hannifin Manufacturing Germany GmbH & Co. KG

Pump & Motor Division Europe

Chemnitz, Germany

Installation and setup manual

Bulletin MSG30-2901-INST/UK

2.3. Electrical interfaces, PIN assignment

Check voltage, current, phase and connection prop-

erties before plugging in any electrical component.

Following mating connectors need to be used to

connect the actuator and sensors properly.

Electrical

component

Connector

Mating

Connector

Valve

DT04-2P

DT06-2S

Swash angle sensor

DT04-3P

DT06-3S

Pressure Sensor

DT04-4P

DT06-4S

With correctly installed and mounted mating con-

nector all “DEUTSCH” connectors used meet

protection class IP 67.

PIN assignment - valve:

The terminal assignment of supply and GND is not

important for functionality of the valve.

PIN assignment – swash angle sensor:

PIN assignment – swash angle sensor:

PIN / Terminal

Connection

A

5V / VREF+ / Supply – red

B

0V / VREF- / GND – black

C

Signal – blue

NOTICE

Do not treat the sensor with electro static

painting.

PIN assignment - pressure sensor:

PIN / Terminal

Connection

1

5V / VREF+ / Supply

2

0V / VREF- / GND

3

Signal

4

n.c.

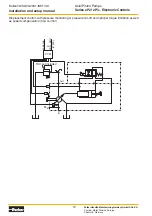

2.4. Wiring recommendations

2.5. Power supply – sensors, reference

voltage

Component

Cross

section

Cable

type

Valve

min.

0,75 mm²

(AWG 18)

Stranded

wire cable

Swash angle sensor

min.

0,5 mm²

(AWG 20)

Pressure Sensor

Output voltage

5V ± 150mV

Max. out voltage drift

0,5mV/°C

Recommended load

current

150mA

Recommended

protection

Overload, SCB (Short

to Battery) , SCG

(Short to Ground)

Diagnostic

Over-/ undervoltage

recommended for

error detection

Recommended over-/

undervoltage threshold

±500mV from

nominal value