Parker EME

Maintenance

192-550004N2 ETH ATEX November 2013

19

2.2

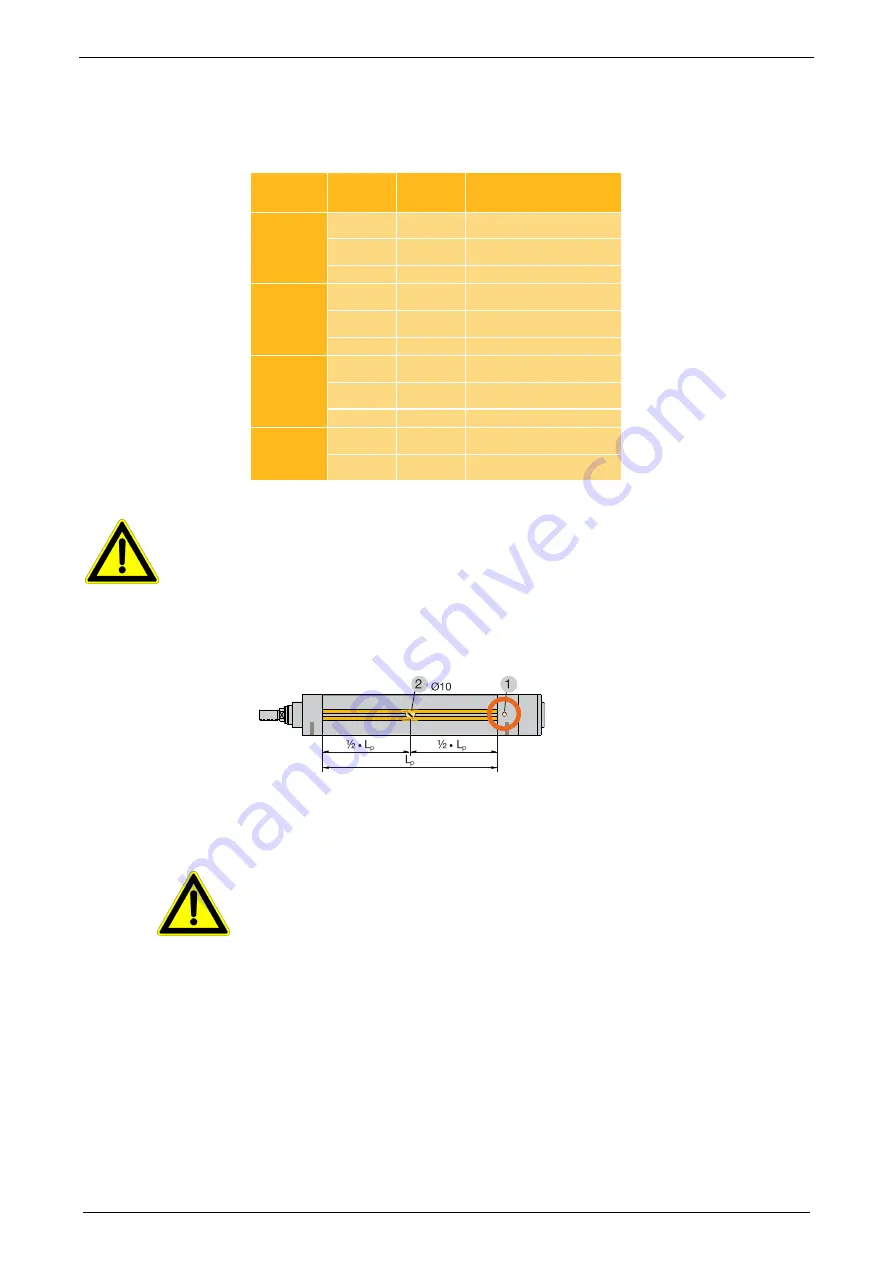

Lubricating intervals and amount of lubricant for ATEX

ETH electro cylinders

Screw

Interval

Amount of lubricant

ETH032

M05

80 km

1.3 cm

3

M10

160 km

1.6 cm

3

M16

250 km

2.1 cm

3

ETH050

M05

80 km

1.6 cm

3

M10

160 km

1.9 cm

3

M20

320 km

2.7 cm

3

ETH080

M05

80 km

3.1 cm

3

M10

160 km

4.4 cm

3

M32

510 km

7.8 cm

3

ETH100

M10

80 km

14 cm

3

M20

160 km

17 cm

3

Lubricant

Do only use "Klüber NBU15" lubricating grease for standard

cylinders!

For applications in food related areas, "Klübersynth UH1 64-62" grease is used (customized version).

2.2.1.

Greasing via central lubrication port (standard)

1: Central lubrication (standard)

2: Central lubrication (Option)

Make sure that all external stops are removed.

Retreat thrust rod completely so that it touches the rear stop.

Pass internal buffer by 0.5 mm.

ATTENTION!

Ensure by means of control, that the internal buffer is not passed by more than

0.5 mm!

This is the lubricating position.

Use a suitable pipe for the funnel type lubricating nipple, Type D1a4 DIN3405:

Beaked nozzle.

Place the pipe orthogonally onto the lubricating nipple and press.

Use the defined amount of lubricant.

The amount of lubricant applied can be defined by the number of pump strokes.

Pump the stated amount of grease onto a balance, while counting the pump

strokes.

Summary of Contents for ETH

Page 5: ...Parker EME Introduction 192 550004N2 ETH ATEX November 2013 5 1 1 Mounting explanation ...

Page 25: ...Parker EME Index 192 550004N2 ETH ATEX November 2013 25 ...

Page 26: ...Index ETH ATEX 26 192 550004N2 ETH ATEX November 2013 ...

Page 27: ...Parker EME Index 192 550004N2 ETH ATEX November 2013 27 ...