131

– Pvd3665_Gb_Ex_August 2022

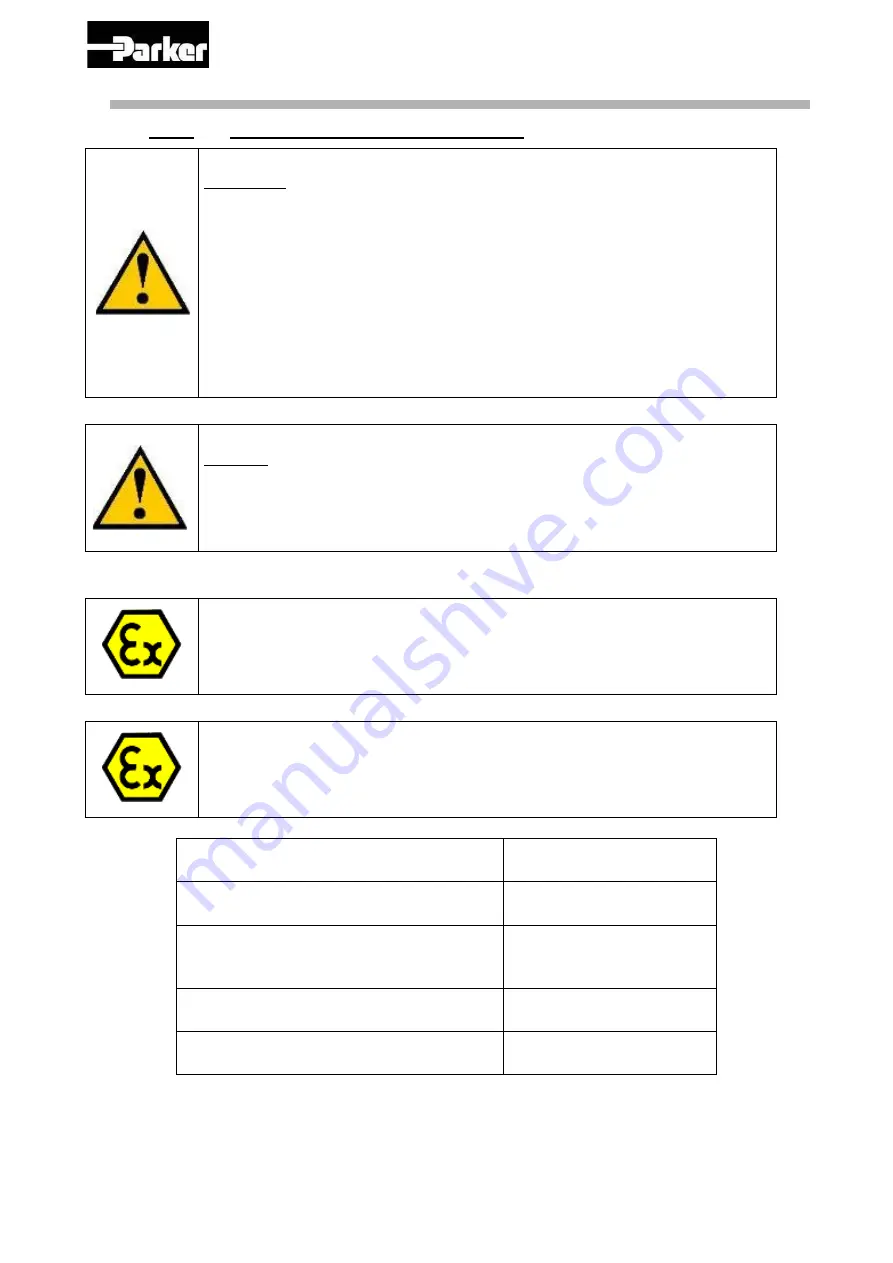

4.4. Maintenance Operations

4.4.1.

Summary maintenance operations

Generality

DANGER: The installation, commission and maintenance operations

must be performed by qualified personnel, in conjunction with this

documentation.

The qualified personnel must know the safety (C18510 authorization,

standard VDE 0105 or IEC 0364) and local regulations.

They must be authorized to install, commission and operate in

accordance with established practices and standards.

Please contact PARKER for technical assistance.

Special requirements for ATEX servomotors

Operation

Periodicity

Clean the motor

Every year

Motor inspection (vibration changes,

temperature changes, tightening

torques on all scews)

Every year

Cable inspection, no degradation

(colour, flexibility

, cracks…)

Every year

Bearing replacement

Every 20 000h

Danger: before any intervention the motor must be disconnected from

te power supply.

Due to the permanent magnets, a voltage is generated at the terminals

when the motor shaft is turned

If a screw assembly of the enclosure need to be replaced, the new

screw will must be quality 8.8 or higher for EX3-EX4-EX6 or quality

12.9 or higher for EX8. For the EX8 in UL version the screw must be

quality 14.9 or higher.

If the motor is used in dust explosive atmospheres, do not forget to do

a regular cleaning in order to avoid the deposits of dusts.

Summary of Contents for EX Series

Page 1: ...1 Pvd3665_Gb_Ex_August 2022 Servomotors EX Series Technical Manual PVD 3665 EX...

Page 2: ...2 Pvd3665_Gb_Ex_August 2022...

Page 3: ...3 Pvd3665_Gb_Ex_August 2022...

Page 4: ...4 Pvd3665_Gb_Ex_August 2022...

Page 5: ...5 Pvd3665_Gb_Ex_August 2022...

Page 6: ...6 Pvd3665_Gb_Ex_August 2022...

Page 7: ...7 Pvd3665_Gb_Ex_August 2022...

Page 8: ...8 Pvd3665_Gb_Ex_August 2022...

Page 9: ...9 Pvd3665_Gb_Ex_August 2022...

Page 10: ...10 Pvd3665_Gb_Ex_August 2022...

Page 11: ...11 Pvd3665_Gb_Ex_August 2022...

Page 12: ...12 Pvd3665_Gb_Ex_August 2022...

Page 13: ...13 Pvd3665_Gb_Ex_August 2022...

Page 14: ...14 Pvd3665_Gb_Ex_August 2022...

Page 15: ...15 Pvd3665_Gb_Ex_August 2022...

Page 16: ...16 Pvd3665_Gb_Ex_August 2022...

Page 17: ...17 Pvd3665_Gb_Ex_August 2022...

Page 18: ...18 Pvd3665_Gb_Ex_August 2022...

Page 19: ...19 Pvd3665_Gb_Ex_August 2022 Compliance with UL standards...

Page 20: ...20 Pvd3665_Gb_Ex_August 2022 Compliance with UL standards...

Page 73: ...73 Pvd3665_Gb_Ex_August 2022 3 3 Dimension drawings 3 3 1 EX310E...

Page 74: ...74 Pvd3665_Gb_Ex_August 2022 3 3 2 EX420E EX430E...

Page 75: ...75 Pvd3665_Gb_Ex_August 2022 3 3 3 EX620E EX630E...

Page 76: ...76 Pvd3665_Gb_Ex_August 2022 3 3 4 EX820E EX840E EX860E...

Page 77: ...77 Pvd3665_Gb_Ex_August 2022 3 3 5 EX310 C CCC...

Page 78: ...78 Pvd3665_Gb_Ex_August 2022 3 3 6 EX420 C EX430 C CCC...

Page 79: ...79 Pvd3665_Gb_Ex_August 2022 3 3 7 EX620 C EX630 C CCC...

Page 80: ...80 Pvd3665_Gb_Ex_August 2022 3 3 8 EX820 C EX820 C EX820 C CCC...

Page 81: ...81 Pvd3665_Gb_Ex_August 2022 3 3 9 EX310U...

Page 82: ...82 Pvd3665_Gb_Ex_August 2022 3 3 10 EX420U EX430U...

Page 83: ...83 Pvd3665_Gb_Ex_August 2022 3 3 11 EX620U EX630U...

Page 84: ...84 Pvd3665_Gb_Ex_August 2022 3 3 12 EX820U EX840U EX860U...

Page 93: ...93 Pvd3665_Gb_Ex_August 2022 3 8 5 Mains supply connection diagrams 3 8 5 1 EX310E...

Page 94: ...94 Pvd3665_Gb_Ex_August 2022 3 8 5 2 EX420E EX430E...

Page 95: ...95 Pvd3665_Gb_Ex_August 2022 3 8 5 3 EX620E EX630E...

Page 96: ...96 Pvd3665_Gb_Ex_August 2022 3 8 5 4 EX820E EX840E EX860E...

Page 97: ...97 Pvd3665_Gb_Ex_August 2022 3 8 5 5 EX310 C CCC...

Page 98: ...98 Pvd3665_Gb_Ex_August 2022 3 8 5 6 EX420 C EX430 C CCC...

Page 99: ...99 Pvd3665_Gb_Ex_August 2022 3 8 5 7 EX620 C EX630 C CCC...

Page 100: ...100 Pvd3665_Gb_Ex_August 2022 3 8 5 8 EX820 C EX840 C EX860 C CCC...

Page 101: ...101 Pvd3665_Gb_Ex_August 2022 3 8 5 9 EX310U...

Page 102: ...102 Pvd3665_Gb_Ex_August 2022 3 8 5 10 EX420U EX430U...

Page 103: ...103 Pvd3665_Gb_Ex_August 2022 3 8 5 11 EX620U EX630U...

Page 104: ...104 Pvd3665_Gb_Ex_August 2022 3 8 5 12 EX820U EX840U EX860U...