L75 Lubricator

IS-L75

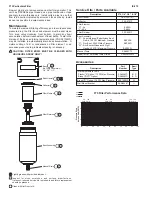

Dip Tube

Bowl Gasket

Bowl Kit

Body / Bypass

Assembly

1/4", 3/8", 1/2"

(Not Sold Separately)

Adjustment

Knob

Sight Dome

Assembly

O-Ring

Drip Spout

Fill Plug Assembly

Check Ball (Check Stud)

Check Stud

Check Ball (Dip Tube)

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface imperfections.

If present, reduced service life is probable and future

replacement should be planned.

Clean with lint-free cloth.

5

4

3

2

1

0

10

20

30

40

50

60

70

80

90

100

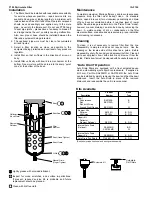

L75 Lubricator Performance Data

Pressure Drop

Across Unit (PSIG)

02

03

04

25

PSIG

25

PSIG

25

PSIG

100

PSIG

100

PSIG

100

PSIG

Product

Bowl

Description

Number

Type

Bowl Kit*

Polyurethane with

Polyethylene Bowl Guard

BKL55B

B

Zinc

BKL55D

D

Zinc with Wrap

Around Sight Gauge

BKL55W

W

Bowl Gasket

GSK-F55-1011

B, D, W

Sight Dome Repair Kit

RKL100/20SA-2/M1

B, D, W

Includes:

Adjusting Knob

—

Sight Dome Assembly

—

Drip Spout

—

O-Ring

—

Fill Plug Assembly

SA606B4

—

Button Head Fill Fitting

SAA606C109-1

—

Wall Mount Bracket

SAR55Y57

—

Check Ball (Check Stud)

604Y106

—

Check Stud

L55-0761P

—

Dip Tube

L75-0741

—

Check Ball (Dip Tube)

506Y106

—

*For “X9” bowl with manual drain option, replace “L” with “F” (e.g., BKF55B).

Service Kits / Parts Available

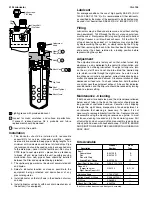

Filling

Lubricators may be filled either under no pressure or under pressure

- without shutting down equipment. To fill through the fill port, a

long spout oil can must be used. Slowly remove fill plug and insert

tip of spout to bottom of fill port recess or oil blow back will occur.

Fill to within 1/2" of top of bowl using correct oil. These lubricators

may also be fitted with Button Head Fill Fittings (SAA606C109-1)

to aid in refilling through the use of a bucket pump.

Lubricator Adjustment

The adjustment knob is factory set so that, when turned fully

clockwise, no oil is delivered to the venturi for atomization, and

equipment is not being lubricated. To initially adjust oil drip rate,

turn on the air, start flow and set knob to obtain the desired

drip rate, which is visible through the sight dome. After system

reaches normal operating temperature, fine tune the drip as

needed. As a start, one to two drops per minute is suggested,

correct lubrication being a matter of experience and demand.

Clockwise rotation of knob decreases oil feed rate. To check

lubrication, hold thumbnail or a mirror near the equipment

exhaust. A heavy film indicates over-lubrication and the drip rate

should be reduced by turning knob to a lower setting. After final

setting has been achieved, the knob may be removed to make

the adjustment mechanism tamper-resistant.

Cycling Applications

If the lubricator is to be used in a cycling application, the

conditions must be as follows:

• The lubricator must stay pressurized during On

AND

Off

cycles.

• On cycle time must be at least 15 seconds, and

• The flow rate during each on cycle must be at least 4 SCFM.