Solenoid Quick Dump Valve 1/4", 3/8" & 1/2" S75 & 3/8", 1/2" & 3/4" S105

IS-S75/S105

Wiring Instructions

!

CAUTION:

An interruption of 10 milliseconds or greater to

the power supplied to the solenoid of a solenoid operated

valve may cause the valve to shift. Provision must be

made to prevent power interruption of this duration to

avoid unintended, potentially hazardous, consequences.

NOTE:

In addition to the following instructions, follow all requirements

for local and national electrical codes.

Electrical Connection

Valves with 3-Pin male terminals should have power connected to

the parallel terminals. Ground should be connected to the

perpendicular terminal.

Override Operation

The flush non-locking manual override is located on the body of

the solenoid pilot. To operate the override, place a small screwdriver

in the slot of the override and turn approximately 45° in either

direction until the solenoid pilot actuates. The solenoid pilot will

remain actuated until the override is released. When released, the

solenoid pilot de-actuates.

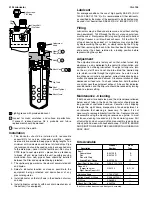

Solenoid Replacement

To replace the solenoid,

remove the solenoid nut and

pull solenoid off and replace

with the correct voltage

solenoid. Replace solenoid

nut and tighten finger tight.

See Figure 1.

Voltage

Coil No.

24VDC

2EV103

24VAC

2EV102

110VAC

2EV105

A

E

B

D

F

G

C

H

Solenoid Nut

(Finger Tight)

Solenoid

Cover

Plunger

Assembly

Spring

Body

Bottom Spring

Screw

Torque: 2.8 to 4.5 Nm

(25 to 40 in. lb.)

U-Cup*

O-ring*

O-ring* (2)

Gasket*

Disc Holder

Assembly*

Bottom Plug

Torque: 4.5 to 6.8 Nm

(40 to 60 in. lb.)

A

C

B

D

E

F

G

H

Solenoid

Solenoid Nut

(Finger Tight)

Cover

Plunger

Assembly

Spring

Body

Bottom Spring

Screw

Torque: 2.8 to 4.5 Nm

(25 to 40 in. lb.)

U-Cup*

O-rings*

O-ring* (2)

Gasket*

Disc Holder

Assembly*

Bottom Plug

Torque: 4.5 to 6.8 Nm

(40 to 60 in. lb.)

S75

S105

Figure 1

Dimensions:

OUT

IN

OUT

IN

S75

S105

S75

S105

Service

!

Caution: Disconnect or shut off air and electrical supply

and exhaust pressure before servicing unit.

!

Caution: Grease packets are supplied with kits for

lubrication of seals. Use only mineral based grease or

oils. Do not use synthetic oils such as esters. Do not use

silicones.

Note: After servicing unit, turn on air and electrical

supply and check

for leaks. If leakage occurs, do not operate – conduct repairs

and retest.

Note : Items marked with an * are included in the service kit.

1. Remove the four Screws that retain the Cover and remove Cover.

Next remove Punger with Seals and Spring from Body.

2. Remove Bottom Plug by unscrewing it from the Body. Next

remove Bottom Spring, Disc Holder Assembly and Gasket.

3. Clean, and carefully inspect parts for wear and / or damage.

If replacement is necessary, use parts from service kit.

4. Lubricate O-rings and U-cup with grease (supplied with kit).

5. Install Gasket into Body. Then install Disc Holder, Bottom Spring

and Bottom Plug into Body. See Figure 1 for torque value.

6. Install Punger with Seals into the Body. Install two O-rings between

Body and Cover (make sure air passages are aligned properly),

install four Screws and tighten per Figure 1.

Service Kits Available:

Description

S75

S105

Service Kit

RKS75

RKS105

There may be extra parts in the kit.

Model

Port

A

B

C

D

E

F

G

H

Size

S75

3/8"

2.19

4.72

2.06 1.50

1.66

.72

2.56

1.90

(56)

(120)

(52)

(38)

(42)

(18)

(65)

(48)

S105

1/2"

3.03

5.25

2.75 1.84

2.53

.84

2.56

1.90

(77)

(133)

(70)

(47)

(64)

(21)

(65)

(48)

Inches (mm)