SC75 & SC105 Soft Start Valve

IS-SC105

2

Voltage

Coil No.

24VDC

2EV103

110VAC

2EV105

!

Function

The Soft Start valve is a 3-Port valve which supplies air in a

controlled reliable manner to pneumatic systems and has the

quick exhaust features of a dump valve. This valve replaces

conventional main valves.

The Soft Start valve operates much like a standard 3-Way

valve. When the valve is installed Port 2 is connected to Port

3 (downstream system is exhausted to atmosphere). When a

signal is received at the pilot operator, the connection between

Port 2 and 3 is closed. At the same time, supply air from Port 1 is

connected to Port 2 through the adjustable throttle, (Adjustment

Needle).

When the downstream pressure reaches a specific point, the

main poppet opens and permits full air flow through the valve.

The table shows the relationship between the inlet pressure and

the downstream pressure at which the main valve opens.

When the pilot signal is removed, the valve returns to its initial

position and the downstream air is dumped rapidly through

Port 3.

Port Connections

1. Connect inlet air supply to Port 1.

2. Connect mufflers (or plumb exhaust) from Port 3.

3. Connect cylinder Port 2 to cylinder or other system devices to

be supplied air.

4. Signal Connection - Soft Start valves may be remotely

controlled electrically.

a. For solenoid pilot operated valves, see the instructions

under “WIRING INSTRUCTIONS.”

Wiring Instructions

!

CAUTION: An interruption of 10 milliseconds or greater

to the power supplied to the solenoid of a solenoid

operated valve may cause the valve to shift. Provision

must be made to prevent power interruption of this

duration to avoid unintended, potentially hazardous,

consequences.

NOTE: In addition to the following instructions, follow all requirements for

local and national electrical codes.

Attach an electrical cable with connector (that conforms to the

DIN 43650, Form B pattern) to the terminals of the solenoid. Do

not attach or remove the connectors until power is off.

Electrical Connection

Valves with 3-Pin male terminals should have power connected

to the parallel terminals. Ground should be connected to the

perpendicular terminal. Use only connectors that comply with

DIN 43650, Form B (11 mm blade spacing).

Override Operation

The flush non-locking manual override is located on the body

of the solenoid pilot. To operate the override, push in on the

override until the solenoid pilot actuates. The solenoid pilot will

remain actuated until the override is released. When released,

the solenoid pilot de-actuates.

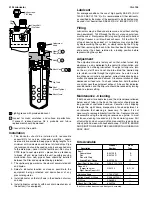

Adjustment

The filling speed and pressurization of downstream circuit

is accomplished by a Needle Valve located in the Cover

(See Figure 1). Adjustment is performed using a standard flat

blade screwdriver as indicated in Figure 1. Adjustments can be

made by performing start-up test and adjusting the Needle Valve

from zero to a maximum of 4 turns open until desired equipment

speed is reached.

!

Caution: Do not turn needle valve more than 4 turns out

from closed position as it is a pressure circuit and could

blow out with force.

The adjustment of the initial airflow rate into the downstream

side of the soft-start valve is done with the Needle Valve. Turning

Needle Valve counterclockwise will decrease amount of time to fill

downstream circuit. Turning Needle Valve clockwise will increase

amount of time to fill downstream circuit.

Once the desired start-up speed of the downstream circuit has

been reached, the adjustment area can be blocked off to prevent

tampering by inserting the Lockout Pin provided in the package.

Any further adjustments will require the removal of the Lockout

Pin as shown in Figure 2.

Solenoid Replacement

To replace the solenoid, remove the solenoid nut and pull

solenoid off and replace with the correct voltage solenoid.

Replace solenoid nut and tighten finger tight. See Figure 3.

Service

Caution: Disconnect or shut off air supply and exhaust

pressure before servicing unit.

Figure 1

Adjustment

Figure 2

Lockout Pin Removal

Inlet

Downstream

Pressure

Pressure for

Full Flow

75 PSIG

50 PSIG

100 PSIG

55 PSIG

125 PSIG

60 PSIG

150 PSIG

65 PSIG

Start-Up Of Soft Start

Flow

Regulating

Needle

Valve

Pilot Air Vent

Pressure

Begins to

Ramp Up

Solenoid

Energized

100 PSIG

IN

OUT

Full Open

Full Flow

at 65% of

Inlet Pressure

Solenoid

Energized

100 PSIG

IN

OUT

Exhaust and Closed

Pressure

Dumps to

Zero

Solenoid

De-Energized

100 PSIG

IN

OUT