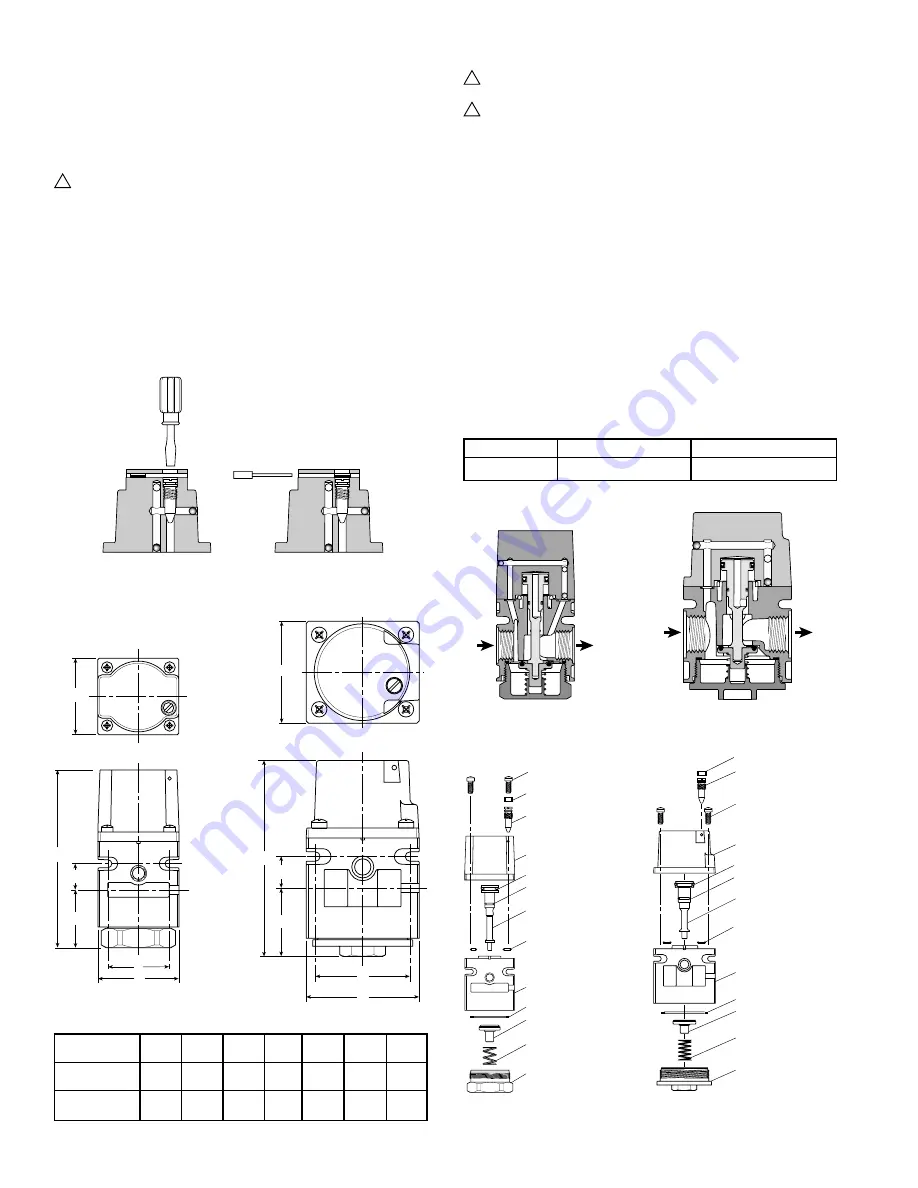

Auto Pilot Soft Start Valve 1/4", 3/8" & 1/2" SSA75 & 3/8", 1/2" & 3/4" SSA105

IS-SSA75/SSA105

SSA75

SSA105

Figure 3

Dimensions:

SSA75

SSA105

SSA75

SSA105

Figure 1

Adjustment

Figure 2

Lockout Pin Removal

OUT

IN

A

D

F

B

C

E

Cover

Plunger

Assembly

Body

Bottom Spring

Needle Valve &

O-ring

Lockout Pin

Screw

Torque: 2.8 to 4.5 Nm

(25 to 40 in. lb.)

U-Cup*

O-ring*

O-ring* (2)

Gasket*

Disc Holder

Assembly*

Bottom Plug

Torque: 4.5 to 6.8 Nm

(40 to 60 in. lb.)

OUT

IN

A

E

B

D

F

C

Screw

Torque: 2.8 to 4.5 Nm

(25 to 40 in. lb.)

Needle Valve &

O-ring

Lockout Pin

Cover

U-Cup*

O-ring*

O-ring* (2)

Plunger

Assembly

Body

Gasket*

Disc Holder

Assembly*

Bottom Spring

Bottom Plug

Torque: 4.5 to 6.8 Nm

(40 to 60 in. lb.)

Adjustment

The filling speed and pressurization of downstream circuit is

accomplished by a Needle Valve located in the Cover

(See Figure 1). Adjustment is performed using a standard flat

blade screwdriver as indicated in Figure 1. Adjustments can be

made by performing start-up test and adjusting the Needle Valve

from zero to a maximum of 4 turns open until desired equipment

speed is reached.

!

Caution: Do not turn needle valve more than 4 turns out

from closed position as it is a pressure circuit and could

blow out with force.

The adjustment of the initial airflow rate into the downstream side

of the soft-start valve is done with the Needle Valve. Turning Needle

Valve counterclockwise will decrease amount of time to fill

downstream circuit. Turning Needle Valve clockwise will increase

amount of time to fill downstream circuit.

Once the desired start-up speed of the downstream circuit has

been reached, the adjustment area can be blocked off to prevent

tampering by inserting the Lockout Pin provided in the package.

Any further adjustments will require the removal of the Lockout Pin

as shown in Figure 2.

Service

!

Caution: Disconnect or shut off air supply and exhaust

pressure before servicing unit.

!

Caution: Grease packets are supplied with kits for

lubrication of seals. Use only mineral based grease or

oils. Do not use synthetic oils such as esters. Do not use

silicones.

Note:

After servicing unit, turn on air supply and check for leaks.

If leakage occurs, do not operate – conduct repairs and retest.

Note :

Items marked with an * are included in the service kit.

1. Remove the four Screws that retain the Cover and remove Cover.

Next remove Plunger with Seals from Body.

2. Remove Bottom Plug by unscrewing it from the Body. Next

remove Bottom Spring, Disc Holder Assembly and Gasket.

3. Clean, and carefully inspect parts for wear and / or damage.

If replacement is necessary, use parts from service kit.

4. Lubricate O-rings and U-cup with grease (supplied with kit).

5. Install Gasket into Body. Then install Disc Holder, Bottom Spring

and Bottom Plug in to Body. See Figure 3 for torque value.

6. Install Punger with Seals into the Body. Install two O-rings between

Body and Cover (make sure air passages are aligned properly),

install four Screws and tighten per Figure 3.

Service Kits Available:

Description

SSA75

SSA105

Service Kit

RKSS75

RKSS105

There may be extra parts in the kit.

Model

Port

A

B

C

D

E

F

Size

SSA75

3/8"

2.19

4.72

2.06

1.50

1.66

.72

(56)

(120)

(52)

(38)

(42)

(18)

SSA105

1/2"

3.03

5.25

2.75

1.84

2.53

.84

(77)

(133)

(70)

(47)

(64)

(21)

Inches (mm)