219

d

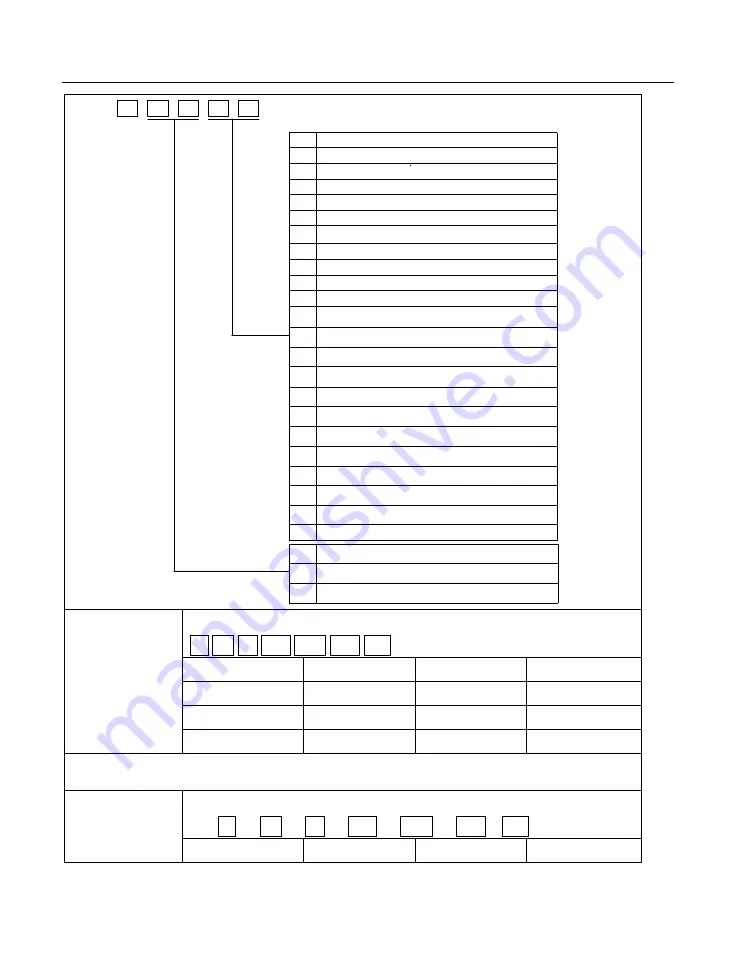

Control mode setting

X

Position pulse mode

Internal register torque mode

1

Internal register speed mode

Reserved

0

4

3

2

5

Internal register position mode

6

7

8

9

10

11

12

13

14

15

16

18

19

20

Mix mode of internal register speed and position pulse

Mix mode of internal register speed and internal register torque

Mix mode of internal register speed and internal register position

Mix mode of internal register torque and position pulse

Mix mode of position pulse and internal register position

17

Mix mode of internal register torque and internal register position

Y

0

1

Clockwise as viewed from servo motor shaft

Counterclockwise as viewed from servo motor shaft

Motor forward direction setting

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

21

Bus mode

Sub-index 04h

Encoder frequency-division numbers

PP PV PT CSP CSV CST HM

Setting Range

Setting Unit

Mfr’s Value

Effect

1

~

65535

N/A

—

immediate

Function code

Mapping o

Data type

Accessibility

Po003

N

UINT16

RW

Po003 is used to set frequency-division numbers for each phase.

The entry-into-effect time is 100ms.

Sub-index 06h

Encoder pulse frequency-division numbers denominator

PP PV PT CSP CSV CST HM

Setting Range

Setting Unit

Mfr’s Value

Effect