FL20-S Series

179

PL019

Master Axis Position

Position

Setting Range

Setting Unit

Mfr’s Value

Effect

0~2147483647

N/A

0

Check

4) Digital output setting

PL011

DO valid initial position

Position

Setting Range

Setting Unit

Mfr’s Value

Effect

0~2147483647

N/A

0

Immediate effect

PL013

DO valid ending position

Position

Setting Range

Setting Unit

Mfr’s Value

Effect

0~2147483647

N/A

0

Immediate effect

6.5 Dual Mode

6.5.1 User Parameter Setting

Po001 is two-parameter mode, which is selected by Po001.X.

Parameter

Significance

Remark

Po001= d □ 6

Speed and position pulse command of internal register

Po001= d □ 7

Speed and torque of internal register

Po001= d □ 8

Speed of internal register and speed of external analog

Po001= d □ 9

Speed of internal register and torque of external analog

Po001= d □ 10

Speed and position of internal register

Po001= d □ 11

Torque and position pulse command of internal register

Po001= d □ 12

External analog speed and position pulse command

Po001= d □ 13

External analog torque and position pulse command

Po001= d □ 14

Position pulse command and position of internal register

Po001= d □ 15

External analog speed and torque of internal register

Po001= d □ 16

External analog torque and torque of internal register

Po001= d □ 17

Torque and position of internal register

Po001= d □ 18

External analog speed and torque

Po001= d □ 19

External analog speed and internal register position

Po001= d □ 20

External analog torque and internal register position

Po001= d □ 21

Bus cotrol mode

Po001= d □ 22

Built-in PLC control mode

Summary of Contents for FL20-S Series

Page 1: ......

Page 33: ...FL20 S Series 33 M3 structure Fig 3 1 5 Servo drive structure 3 ...

Page 35: ...FL20 S Series 35 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5 ...

Page 36: ...FL20 S Series 36 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6 ...

Page 37: ...FL20 S Series 37 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7 ...

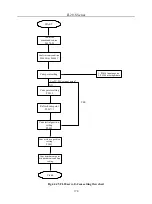

Page 169: ...FL20 S Series 169 Fig 6 4 44FL20E Cam internal frameworkdiagram ...

Page 347: ...FL20 S Series 347 ...