Parker Hannifin Corporation

Actuator Division

Wadsworth, Ohio USA

73

Catalog AU03-0900P-2/NA

XXX

Maintenance Instructions and Service

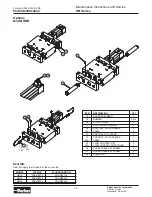

HB Series Thrust & Base Slides

Maintenance Instructions & Parts List

Provide Model Number and Serial Number When Ordering Spare Parts.

HB Series

General

The HB Series products are linear actuators that incorpo-

rate composite or linear recirculating ball bushings and

shaft supports, which provide positive load support and

torque resistance. This manual contains maintenance

instructions, replacement parts information and information

on various options. Consult the factory or product catalog for

additional information.

Specifications:

■

Maximum operating pressure: 150 psi (air)

250 psi (oil) – 2ML cylinder only

750 psi (oil) – 3L cylinder only

■

Operating characteristics: double acting

■

Four support rod sizes: 20, 25, 30 and 35 mm

■

Stroke tolerance: +.030, -.000

■

Mounting: unrestricted

■

Operating temperature range (cylinder):

Standard seals

0 to 165°F

Fluorocarbon seals* 0 to 250°F

■

Filtration requirement: 40 micron filtered, dry air

HBN, HBC, HBT and HBR Thrust Slides

Inspection and Replacement Procedure for Bearings,

Support Shafts and Cylinder:

1. Remove stop collars and bumpers (bumper option).

2. Loosen piston rod locknut and unscrew piston rod from

alignment coupler (HBT, HBR) or tooling plate (HBN,

HBC).

3. Remove tooling plate and support rod assembly from

housing.

4. Remove cylinder bolts and remove cylinder from

housing.

5. Inspect bearings and support shafts. Replace if neces-

sary. (Ball bushings are press fit,composite bushings are

held in place with anaerobic adhesive. Remove bush-

ings from housing only if replacing.)

6. Clean all parts thoroughly.

Reassembly Procedure:

1. Press bearings into housing. Use cylindrical bonding

anaerobic adhesive on composite bushings.

2. Apply a liberal amount of bearing lubricant to ball

bushings. Composite bushings do not require lubrication.

(recommended lubricant is NLG1 grade grease)

3. Replace cylinder and tighten all screws to proper torque

(see table).

4. Screw piston rod into tool plate or alignment coupler and

tighten locknut.

5. Replace bumpers and stop collars if applicable.

HBB Base Slides

Inspection and Replacement Procedure

for Bearings, Support Shafts and Cylinder:

1. Loosen piston rod locknut and unscrew piston rod from

the housing.

2. Remove cylinder bolts and remove cylinder from

housing.

3. Remove support rod screws and end plates.

4. Remove bumpers and stop collars if applicable.

5. Remove support rods from housing.

6. Inspect bearings and support shafts. Replace if neces-

sary. (Ball bushings are press fit, composite bushings are

held in place with anaerobic adhesive. Remove bush-

ings from housing only if replacing.)

7. Clean all parts thoroughly.

Reassembly Procedure:

1. Press bearings into housing. Use cylindrical bonding

anaerobic adhesive on composite bushings.

2. Apply a liberal amount of bearing lubricant to ball

bushings. Composite bushings do not require lubrication.

(recommended lubricant is NLG1 grade grease)

3. Assemble support rods into housing.

4. Replace bumpers and stop collars if applicable.

5. Assemble end plates and support rods.

6. Replace cylinder and tighten all screws to proper torque

(see table).

7. Screw piston rod into housing and tighten locknut.

TORQUE VALUES (ft-lbs)

HB*15

HB*20

HB*25

CYLINDER HEAD BOLT

5

10

10

SUPPORT ROD BOLT

40

60

90

STOP COLLAR BOLT

5

10

15

SHOCK BLOCK SCREW

5

10

15

SHOCK STOP BOLT

5

10

15

SWITCH BLOCK SCREW

1

1

1

Torque Table

Maintenance Instructions