English

4/8

PCW420-650

4 Control

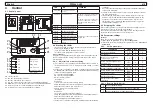

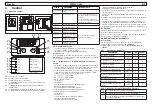

4.1 Control panel

Fig.1

LIV

Low water level

PI

enter

Low pressure

Pump alarm

High pressure

on

HP

TP

LP

off

C

F

I

O

Power supply

PS

4

L

3

L

0

P

L5

L6

L7

L8

L9

L1

P6

P1

P2

P5

P3

P4

L2

Compressor alarm

alarms

WATER

OUT

WATER

IN

LIV

Low water level

PI

enter

Low pressure

Pump alarm

High pressure

on

HP

TP

LP

off

C

F

Power supply

PS

4

L

3

L

L5

L6

L7

L8

L9

L1

P6

P1

P2

P5

P3

P4

L2

Compressor alarm

alarms

P0 Isolator switch.

P1 On key: activates the controller.

P2 Off key: deactivates the controller.

P3 UP key: used to increase the value of a modifi able parameter.

P4 DOWN key: used to decrease the value of a modifi able parameter

P5 Enter key: used to confi rm modifi cations to parameters.

P6 Alarms key: used to reset all manual reset alarms.

LED

ON

FLASHING

L1: yellow

Controller is receiving

power

L2: green

Controller is On

With the controller receiving power

and ‘Off’: an antifreeze heater is

on.

With the controller receiving power

and ‘On’: compressor called for,

but wating for a delay time to

elapse.

L3: red

°C unit of measurement

L4: red

°F unit of measurement

L5: red

High pressure alarm

USER Loop or FACTORY program-

ming mode

L6: red

Low pressure alarm

L7: red

Pump temperature alarm

L8: red

Low water level alarm

L9: red

Compressor protection

alarm

4.2 Starting the chiller

• Connect the power supply to the machine by turning the main

isolator switch QS [P0] to ON.

• Turn the chiller ‘ON’ by pressing the key [P1].

• Set the desired temperature on the controller.

Phases Monitor

If appears on display the alarm “PI1 “(para. 4.6.1), during the start up,

the user must verify the wiring of the input terminals of the discon-

necting switch.

4.2.1

Adjustments at commissioning

a) The chiller is set for operation at a default temperature of 44.6°F (7

°C) with a differential of 7°F (4 °C); to adopt a new setting, see head-

ing 4.5..

b) Verify correct operation of the pump, using the pressure gauge (read

P1 and P0) and checking the pressure limit values (Pmax and Pmin)

indicated on the pump data plate.

P1 = pressure with pump ON

P0 = pressure with pump OFF

Pmin < (P1-P0) < Pmax

- Example n°1.

Conditions:

closed circuit, pressure P0 = 29 PSIg (2 bar)

pump data plate values: Pmin 14PSIg(1 bar)/ Pmax 43PSIg (3 bar)

adjust the valve outlet to give a pressure of

43PSIg (3 bar) < P1< 72PSIg (5 bar)

- Example n°2.

Conditions:

open circuit, pressure P0 = 0 PSIg (0 bar)

pump data plate values: Pmin 14PSIg(1 bar)/ Pmax 43PSIg (3 bar)

adjust the valve outlet to give a pressure of

Pmin 14PSIg(1 bar)/ Pmax 43PSIg (3 bar)

c) Verify correct operation of the pump similarly under normal running

conditions.

Check also that the amperage of the pump is within the limits indi-

cated on the data plate.

d) Switch off the chiller and proceed to top up the hydraulic circuit at

the “SET” temperature.

e) Check that the temperature of the “treated” water does not fall

below 41°F (5 °C) and that the ambient temperature in which the

hydraulic circuit operates does not fall below 41°F (5 °C). If the

temperature is too low, add the appropriate quantity of glycol, as

explained under heading 3.3.2

4.3 Stopping the chiller

When chiller operation is no longer required, turn the chiller off as fol-

lows: press key [P2] to switch the controller ‘Off’.

Do not turn off the main switch QS [P0] to ensure that any antifreeze

protection devices will still receive electrical power.

4.4 Parameter settings

General

There are two levels of protection for parameters:

a) Direct (D): with immediate access,

User-changeable;

b) Password protected (U): password required for access;

Factory-set

parameters.

4.4.1 Chiller

parameters

PARAMETER

CODE

TYPE

DEFAULT

Unit of measurement

C-F

U

0

Unit address

Adr

U

1

Remote on / off enabling

(see para. 4.4.1.1).

rE

U

0

Alarm relay management (see

para. 4.4.1.2)

rAL

U

0

Digital output 9 confi guration

Ud9

U

0

Digital output 10 confi guration

Ud10

U

0

Pump thermal alarm management

AtP

U

1

Chiller hour counter

HUL

U

-

Chiller hour counter

HUH

U

-

Chiller hour counter alarm

threshold

tHU

U

0

4.4.1.1 Remote On / Off mode

0

Remote On/Off disabled

1

Remote On/Off enabled together with local On/Off

2

Remote On/Off only, local On/Off disabled

Summary of Contents for Hyperchill PCW420

Page 2: ......

Page 35: ......

Page 37: ...Ap ndice Appendix Appendice Anexo DATE 14 02 2022 Rev 17 CODE 398H272297...

Page 38: ......

Page 51: ...13 7 5 Circuit diagram PCW420 650 NP PCW650 PCW650 A1...

Page 52: ...14 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 1 of 11...

Page 53: ...15 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 2 of 11...

Page 54: ...16 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 3 of 11...

Page 55: ...17 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 4 of 11...

Page 56: ...18 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 5 of 11...

Page 57: ...19 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 6 of 11...

Page 58: ...20 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 7 of 11...

Page 59: ...21 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 8 of 11...

Page 60: ...22 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 9 of 11...

Page 61: ...23 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 10 of 11...

Page 62: ...24 7 6 Wiring diagram PCW420 510 PCW420 650 Sheet 11 of 11...

Page 63: ...25 7 6 Wiring diagram PCW650 PCW420 650 Sheet 1 of 11...

Page 64: ...26 7 6 Wiring diagram PCW650 PCW420 650 Sheet 2 of 11...

Page 65: ...27 7 6 Wiring diagram PCW650 PCW420 650 Sheet 3 of 11...

Page 66: ...28 7 6 Wiring diagram PCW650 PCW420 650 Sheet 4 of 11...

Page 67: ...29 7 6 Wiring diagram PCW650 PCW420 650 Sheet 5 of 11...

Page 68: ...30 7 6 Wiring diagram PCW650 PCW420 650 Sheet 6 of 11...

Page 69: ...31 7 6 Wiring diagram PCW650 PCW420 650 Sheet 7 of 11...

Page 70: ...32 7 6 Wiring diagram PCW650 PCW420 650 Sheet 8 of 11...

Page 71: ...33 7 6 Wiring diagram PCW650 PCW420 650 Sheet 9 of 11...

Page 72: ...34 7 6 Wiring diagram PCW650 PCW420 650 Sheet 10 of 11...

Page 73: ...35 7 6 Wiring diagram PCW650 PCW420 650 Sheet 11 of 11...

Page 74: ......

Page 75: ......