English

7 / 8

ICEP040-060

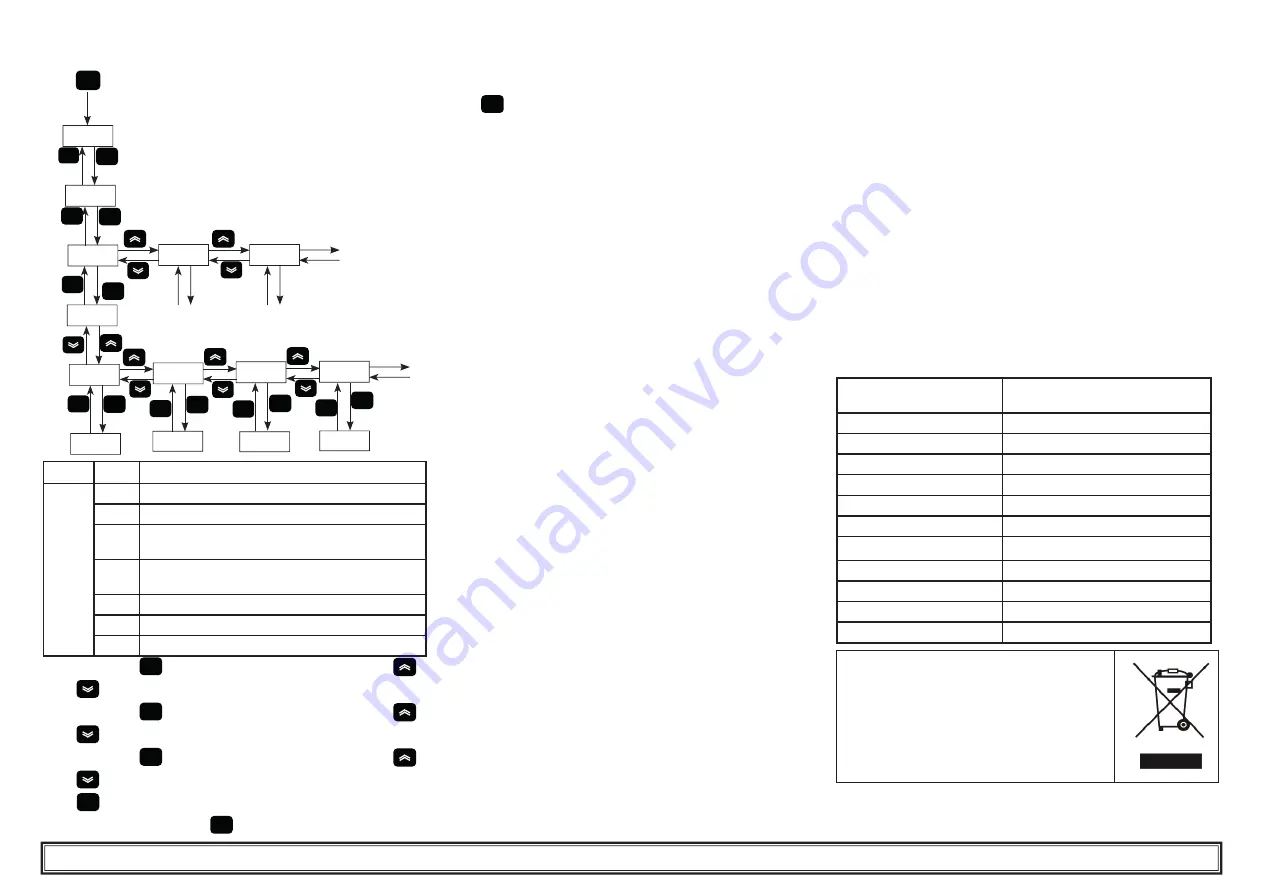

4.9 Alarm/Warning history

ALHi

HySP

esc

set

Y

esc

set

Y

Y

0

1

2

set

HySP

HySC

04

18.06

HySd

HySt

13.46

HyS1

28

set

Y

Y

Y

esc

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

esc

Y

set

Y

esc

Y

Y

set

Y

esc

Y

Y

set

Y

esc

Y

Y

set

Y

Menu

Code

DESCRIPTION

ALHi

HySP

Alarm number

HySC

See alarm code

HySd

See day and month of the alarm

(if the clock option is present)

HySt

See hour and minutes of the alarm

(if the clock option is present)

HyS1

b1 temperature at time of the alarm

HyS2

b2 temperature at time of the alarm

HyS3

SET conditions at time of the alarm

Press the button “

set

” to enter in the menu, using the buttons “

”and “

” select the parameter “

ALHi

”.

Press the button “

set

” to enter in the menu, using the buttons “

”and “

” select the parameter “HySP”.

Press the button “

set

” to enter in the menu, using the buttons “

”and “

” select the alarm number insert (0,1,2......39) and confi rm

with “

set

” (the number 0 is the last alarm started) .

“HySP” appears again, press “

set

” to enter and see the date of the

alarm: “HySC” code (es:HP), “HySd” Date (day, month), “HySt” hour

(hour, minutes), “HyS1” “HyS2” “HyS3” sensor b1, b2 and set when the

alarm occurred.

Press “

esc

” to exit.

4.10 Automatic restart

In the event of a power failure, when power is restored the chiller will

assume the On-Off status held at the moment the power was lost.

5 Maintenance

a) The machine is designed and built to guarantee continuous opera-

tion; however, the life of its components depends on the maintenan-

ce performed.

b) When requesting assistance or spare parts, identify the machine

(model and serial number) by reading the data plate located on the

unit.

www.polewr.com

.

c) Circuits containing 5t < xx < 50t of CO2 are checked to identify

leaks at least once a year.

Circuits containing 50t < xx < 500t di CO2 are checked to identify

leaks at least once every six months. ((EU) No. 517/2014 art. 4.3.a,

4.3.b).

d) For machines containing 5t CO2 ore more, the operator must keep a

record stating the quantity and type of refrigerant used, an quantities

added and that recovered during maintenance operations, repairs

and fi nal disposal ((EU) No. 517/2014 art. 6). .An example of this

record sheet can be downloaded from the site: www.polewr.com.

5.1 General instructions

!

Before performing any maintenance, make sure the power to the

refrigerator is disconnected.

Y

Always use the Manufacturer’s original spare parts: otherwise the

Manufacturer is relieved of all liability regarding machine malfunctio-

ning.

Y

In case of refrigerant leakage, contact qualifi ed and authorized

personnel.

Y

The Schrader valve must only be used in case of machine malfun-

ction: otherwise any damage caused by incorrect refrigerant charging

will not be covered by the warranty.

5.2 Preventive maintenance

To guarantee lasting maximum chiller effi ciency and reliability, carry out:

a)

Z

every month -

clean the condenser fi ns (for biogas version);

b)

Z

every 6 months -

clean the condenser fi ns and make sure

compressor electrical absorption is within the dataplate values;

c)

Z

kit for maintenance

.(par.7.5)

• kit for maintenance;

• service kit;

• individual spare parts.

5.3 Refrigerant

Z

Charging: any damage caused by incorrect charging carried out

by unauthorized personnel will not be covered by the warranty.

Y

The equipment contains fl uorinated greenhouse gases.

At normal temperature and pressure, the R407C refrigerant is a co-

lourless gas classifi ed in SAFETY GROUP A1 - EN378 (group 2 fl uid

according to Directive PED 2014/68/EU);

GWP (Global Warming Potential) = 1774.

!

In case of refrigerant leakage, air the room.

5.4 Dismantling

The refrigerant and the lubricating oil contained in the circuit must be

recovered in conformity with current local environmental regulations.

The refrigerant fl uid is recovered before fi nal scrapping of the

equipment ((EU) No. 517/2014 art.8).

%

Recycling

Disposal

frame and panels

steel/epoxy resin polyester

tank

aluminium/copper/steel

pipes/collectors

copper/aluminium/carbon steel

pipe insulation

NBR rubber

compressor

steel/copper/aluminium/oil

condensator

steel/copper/aluminium

pump

steel/cast iron/brass

fan

aluminium

refrigerant

R407C (HFC)

valve

brass/copper

electrical cable

copper/PVC

Equipment containing electrical components

must be disposed separately collected with

electrical and electronic waste according to

local and currently legislation.

Summary of Contents for Hyperchill Plus ICEP040

Page 2: ......

Page 130: ...8 8 ICEP040 060 6...

Page 138: ...8 8 ICEP040 060 6...

Page 148: ......

Page 168: ...7 6 Circuit Diagram ICEP040 060 air 19 ICEP040 060...

Page 169: ...Circuit Diagram ICEP040 060 water 20 ICEP040 060...

Page 170: ...7 7 Wiring diagram ICEP040 060 21 ICEP040 060 Sheet 1 12...

Page 171: ...7 7 Wiring diagram ICEP040 060 22 ICEP040 060 Sheet 2 12...

Page 172: ...7 7 Wiring diagram ICEP040 060 23 ICEP040 060 Sheet 3 12...

Page 173: ...7 7 Wiring diagram ICEP040 060 24 ICEP040 060 Sheet 4 12...

Page 174: ...7 7 Wiring diagram ICEP040 060 25 ICEP040 060 Sheet 5 12...

Page 175: ...7 7 Wiring diagram ICEP040 060 26 ICEP040 060 Sheet 6 12...

Page 176: ...7 7 Wiring diagram ICEP040 060 27 ICEP040 060 Sheet 7 12...

Page 177: ...7 7 Wiring diagram ICEP040 060 28 ICEP040 060 Sheet 8 12...

Page 178: ...7 7 Wiring diagram ICEP040 060 29 ICEP040 060 Sheet 9 12...

Page 179: ...7 7 Wiring diagram ICEP040 060 30 ICEP040 060 Sheet 10 12...

Page 180: ...7 7 Wiring diagram ICEP040 060 31 ICEP040 060 Sheet 11 12...

Page 181: ...7 7 Wiring diagram ICEP040 060 32 ICEP040 060 Sheet 12 12...

Page 182: ......