icountBS Bottle Sampler Manual

57

GB

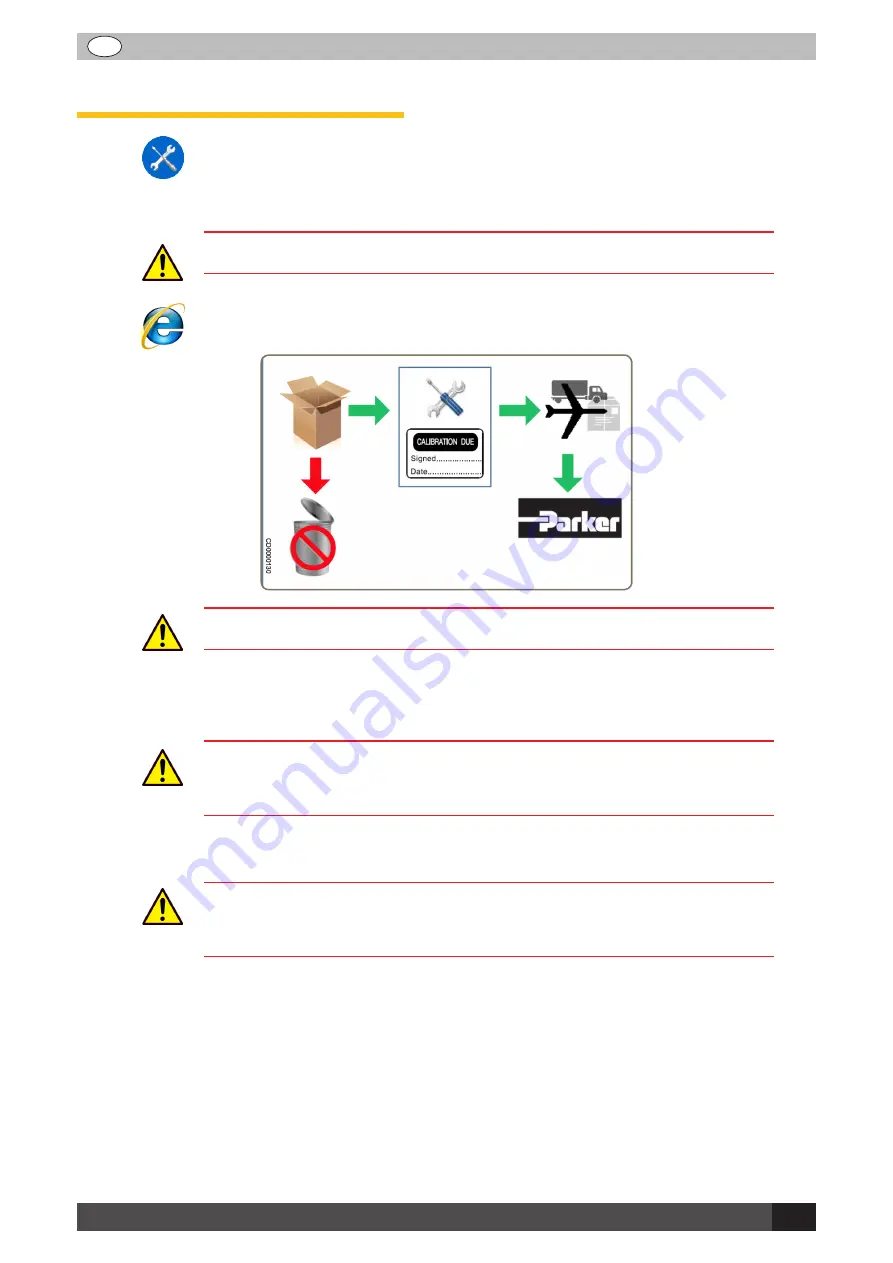

Recalibration and servicing

Parker recommends:

■

■

Re-calibration every 12 months

■

■

Servicing every 12 months

CAUTION: Please contact Parker Hannifin Manufacturing (UK) Ltd if you require

further advice on how to have your unit Calibrated or Serviced.

www.parkerhfde.com/condition-monitoring-solutions/global-service-centres

Please do not dispose of the packing and return the IcountBS in its original case for

any service, calibration or warranty claims.

Verification fluid

CAUTION: A verification of the icountBS can be carried out using specially dosed

samples of oil (Accessory Part Number SERMISC049).

Please contact Parker Hannifin Manufacturing (UK) Ltd if you require further advice.

Li-ion batteries: Transport by Air

WARNING: Please refer to your country/customs’ shipping terms and conditions for

the safe transport of Li-ion batteries. Refer to IATA transport guidelines. (Ref : ICAO

Technical Instruction for the Safe Transport of Dangerous Goods by Air, and the 52nd

Edition (2010) of the IATA Dangerous Goods Regulations (DGR).)