IQ-200 User’s Manual

5

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

Introduction

Laser Safety Information

This product contains a laser-based sensor that

is a Class I product (as defined by 21 CFR,

Subchapter J, of the Health and Safety Act of

1968) when used under normal operation and

maintenance.

WARNING

The use of controls, adjustments, or performance of procedures other than those specified

within this manual may result in exposure to invisible (infrared) radiation that can quickly

cause blindness.

Avoid contact with the internal laser.

The manual contains no procedures for service of

internal parts within this unit. Service should be

performed only by factory - authorized

personnel.

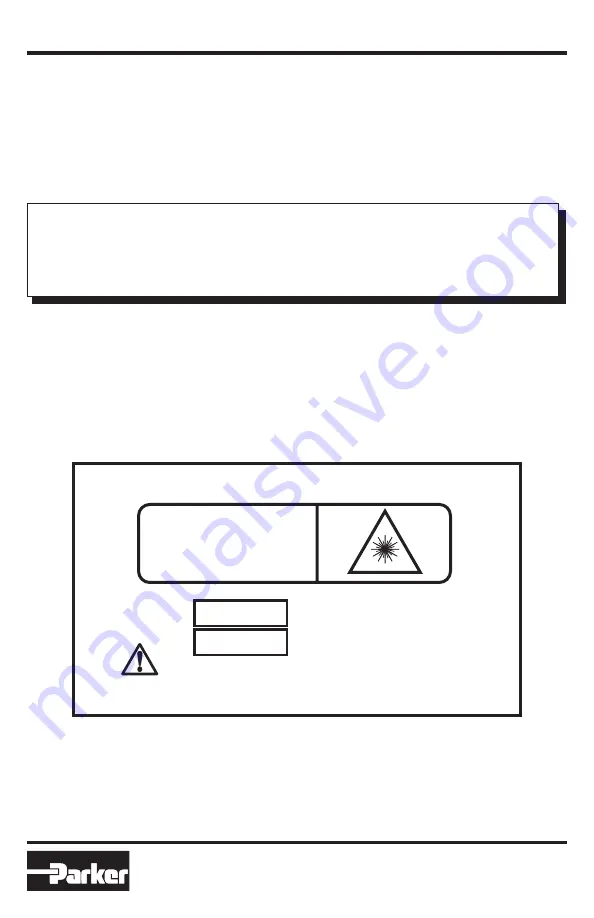

Warning label as specified by 21 CFR 1040.10

A laser classification and identification label is attached to the left

side of the unit. A reproduction of the label is shown below.

Sample of Classification Identification Label.

CLASS 1

LASER PRODUCT

Complies with

CFR Title 21 1040.10

Manufactured:

Month

Year

Warning!

No user serviceable internal parts.

Parker Hannifin Corporation

Hydraulic Filter Division

16810 Fulton County Road #2

Metamora, OH 43540-9714