MX80L Series Product Manual

Chapter 3 - How to Use the MX80

Parker Hannifin Corporation

Daedal Division

Irwin, Pennsylvania

29

Chapter 3 - How to Use the MX80L

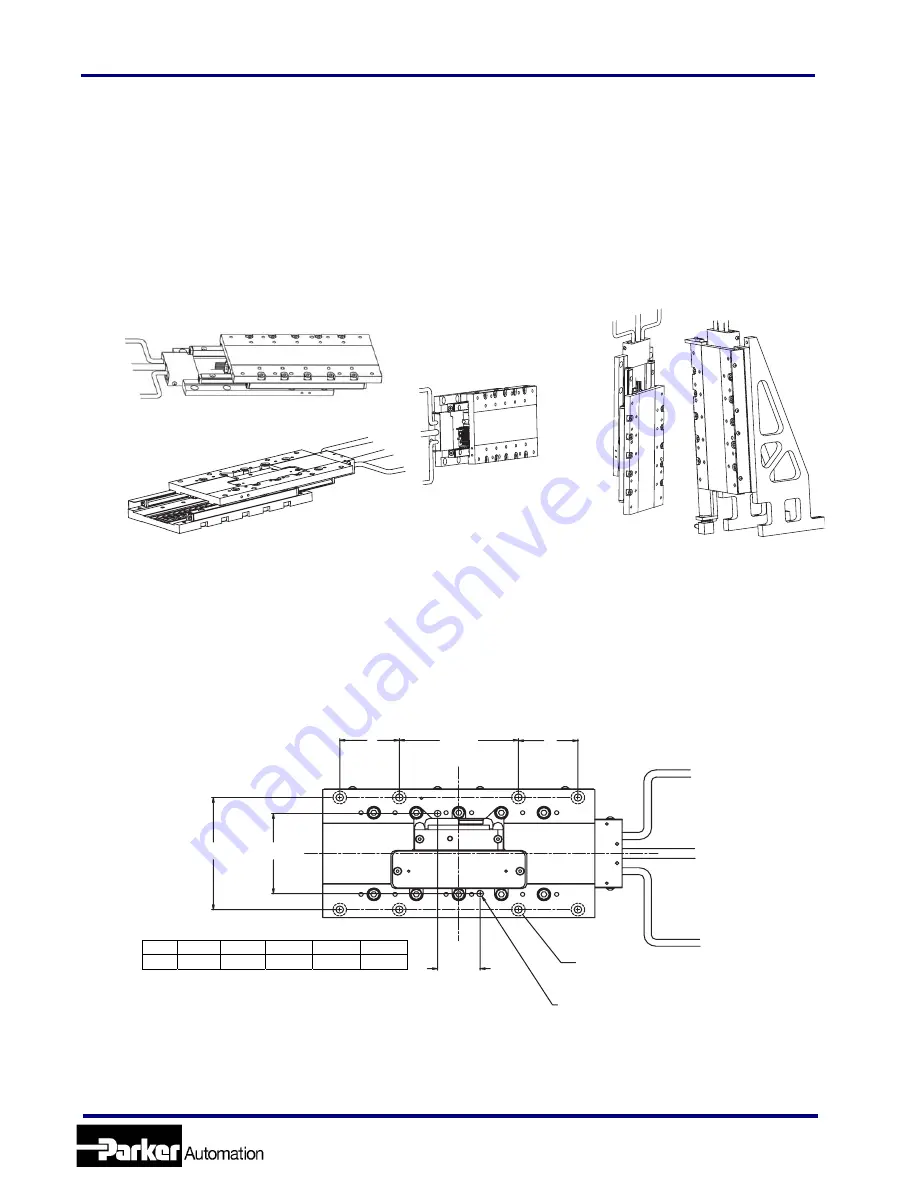

Mounting Orientations

The MX80L can be mounted normal, inverted, side or vertically. For vertical (z-axis) mounting the

pneumatic counter balance is recommended to compensate for the effect of gravity on the carriage and

the load. For all mounting orientations, the cables should be secured as to not interfere with the movement

of the carriage and bearings.

.

Mounting Surface Requirements

Proper mounting of the MX80L is essential to optimize product performance. All specifications are based

on the following conditions:

•

The positioner must be bolted down using all counter bored mounting holes provided (4 on T01 &

T02, 8 on T03, T04, & T05) using M4 socket head cap screws.

70.0 [2.76]

CENTERED

"E

"E"

70.0 [2.76]

CENTERED

50.0 [1.97]

CENTERED

25.0 [0.98]

CENTERED

C-BORED HOLES ON BASE

FOR M4 X 0.7 X 8.0 LENGTH SOCKET CAP HEAD SCREW

Ø4.008

+0.012-0.000

[

Ø0.1578

+0.0005-0.

0000

]

DOWEL PIN HOLES QTY.(2)

BASE

•

The positioner must be mounted to a flat, stable surface, with a flatness error less than or equal to

0.025mm/300mm for operation (specifications will be greatly varied from published specification).

To meet catalog specifications the surface must have a flatness error less than or equal to

0.003mm/300mm for Standard grade and 0.001mm/300mm for Precision grade.

INVERTED

SIDE MOUNTED

HORIZONTAL

P/N 100-9822-02 QTY.(2)

With c’balance and z-bracket

VERTICAL

T01 T02 T03 T04 T05

‘E’ n/a n/a 35.0 65.0 50.0

BASE

www.comoso.com