9

NITROGEN GENERATORS

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

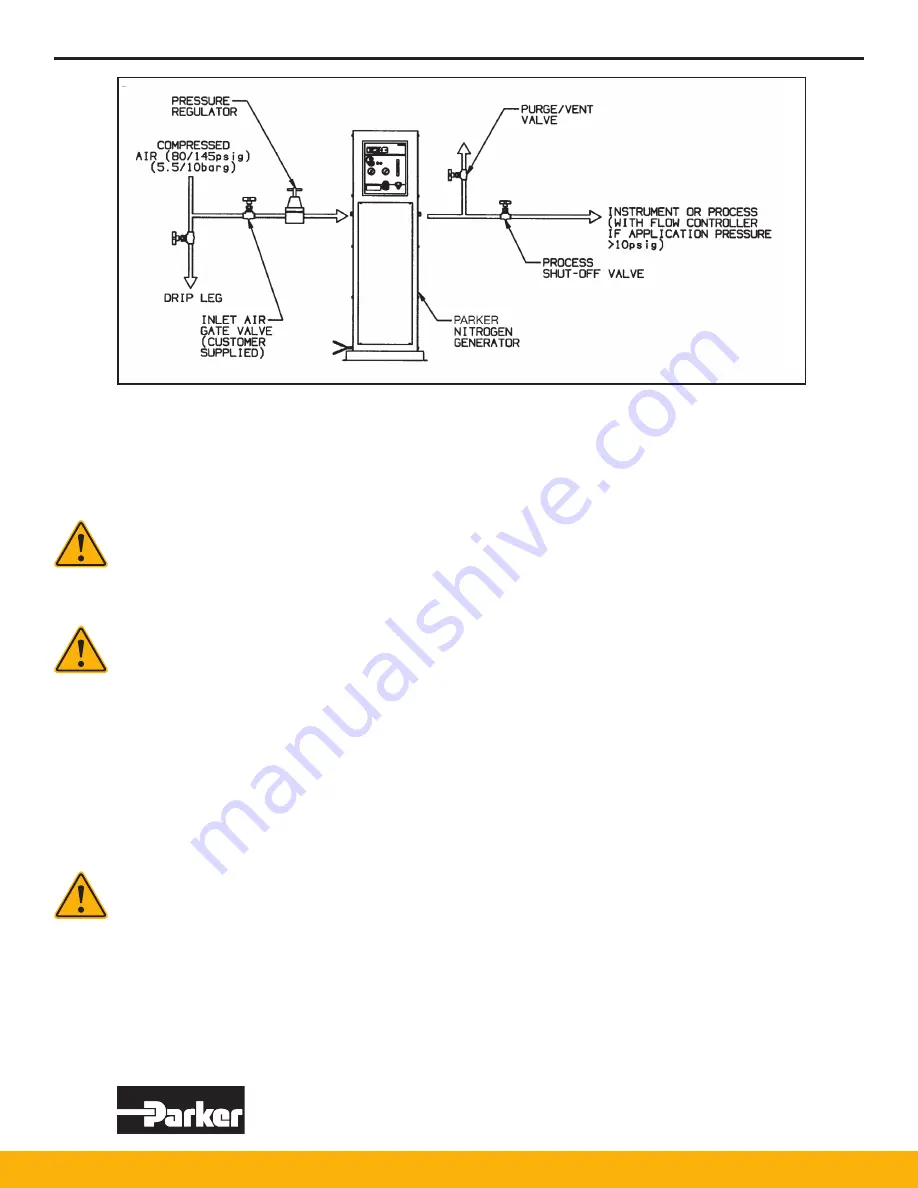

Figure 4

Recommended Installation

6.3 Location

The generator should be located indoors, protected from severe weather conditions, and free

from excessive ambient dust or dirt.

Do not install the generator outdoors.

Ensure that the

ambient temperature of the air surrounding the generator is within the range of that specified for

the generator (see specifications page 20). Allow a minimum of 6" (15 cm) clearance on all sides

of the generator.

The environment surrounding the nitrogen generator should also be adequately ventilated. The

generator creates a 30% to 40% oxygen permeate stream which may pose a flammability risk

in an oxygen sensitive environment.

6.4 Utilities

Compressed Air -

The Parker Nitrogen Generators require a source of compressed air at room

temperature and relatively free of water, compressor oil, hydrocarbons, and particulate matter. An oil

content <0.01 mg/m

3

is recommended. The dewpoint of the incoming air is recommended to be less

than or equal to 40°F (5°C) at 145 psig. The compressed air should be as close to instrument quality

as possible and regulated to a pressure between 60 psig and 145 psig (4.1 barg and 10 barg),

depending on downstream flow and purity desired.

DO NOT OPERATE THE NITROGEN GENERATOR WITHOUT THE FRONT SHEET METAL FILTER

ACCESS PANEL SECURED IN PLACE.

Note:

The piping and fittings on the inlet air delivery system should be at least the same size as the

inlet port on the generator. This will help ensure an adequate supply of air to the generator.

Drain Lines -

The 1/4" plastic drain lines from the first two stages of prefiltration (see Figure 1)

should be piped away to an appropriate disposal container. The liquid in this drainage will consist

primarily of water and compressor oil and should be disposed of properly.