14

NITROGEN GENERATORS

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

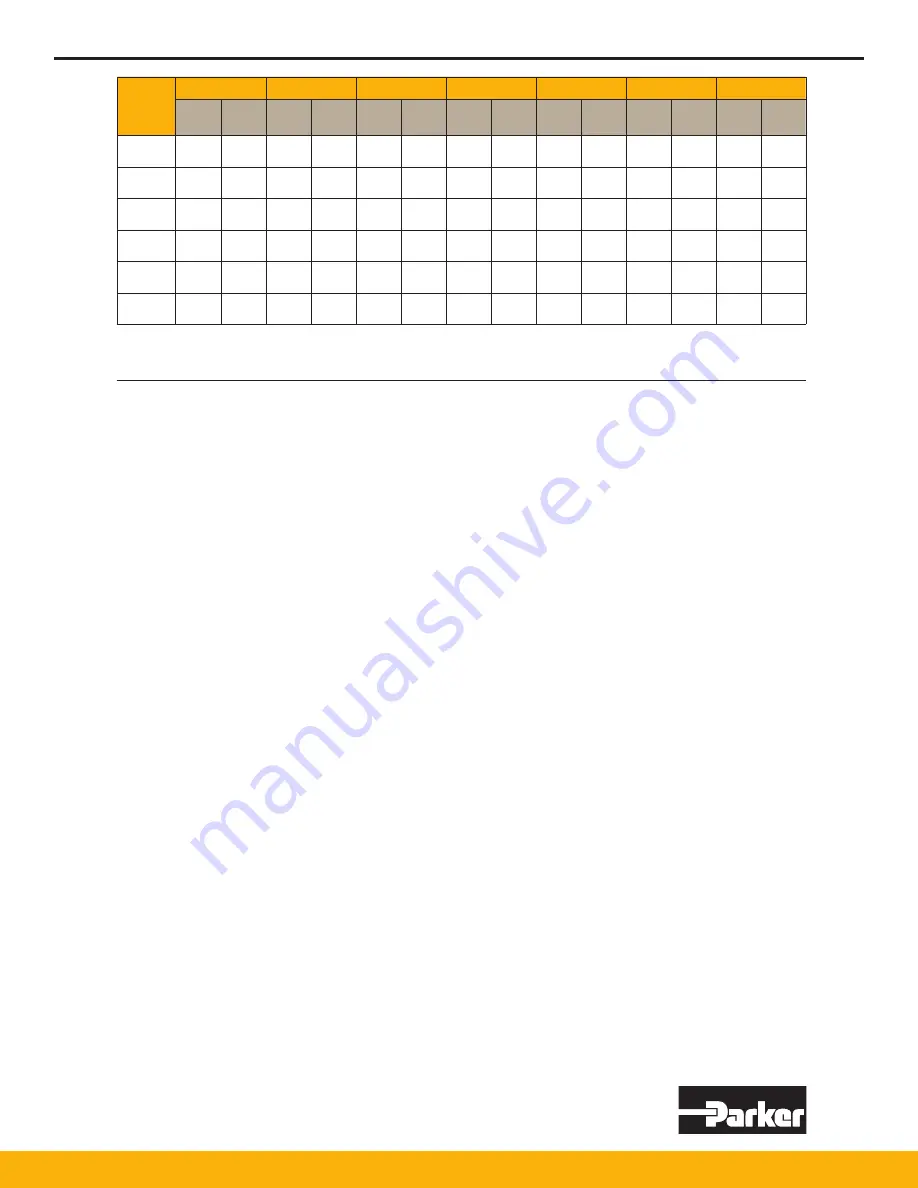

MIN

Purity

% N

2

4 BARG

5 BARG

6 BARG

7 BARG

8 BARG

9 BARG

10 BARG

Meter SLPM Meter SLPM Meter SLPM Meter SLPM Meter SLPM Meter SLPM Meter SLPM

99.50

-

15

-

23

-

31

2.0

40

2.2

50

2.3

58

2.5

67

99.00

-

20

-

29

2.0

42

2.3

54

2.9

67

3.1

79

3.4

92

98.00

-

28

2.1

42

2.8

58

3.3

75

4.2

96

4.4

113

4.7

129

97.00

-

35

2.7

54

3.6

75

4.2

96

5.1

117

5.6

142

6.0

163

96.00

2.3

42

3.4

67

4.4

92

5.0

117

6.1

142

6.7

171

7.4

200

95.00

2.8

50

3.8

75

5.0

104

5.9

138

7.2

167

7.2

200

8.6

233

Model N2-120

9. OPERATION - ADJUSTMENT PROCEDURES

9.1 Atmospheric Pressure Applications (<10 psig / 0.7 barg)

If the Nitrogen Generator is being used to deliver nitrogen at or near atmospheric pressure

(e.g. purging or blanketing applications), use the following procedure for start-up and adjustment

of the system.

1. Open the (customer installed) inlet air gate valve.

2. Adjust the (customer installed) inlet air pressure regulator until the Operating Pressure

gauge (see Figure 1) shows the pressure required to deliver nitrogen at the desired flow

rate (per flowmeter adjustment label).

3. Set the Flow Control Valve to its fully open position.

4. Adjust the Outlet Pressure Regulator (see Figure 1) until the Outlet Pressure gauge displays

the desired process pressure (<10 psig/0.7 barg).

5. Consult the Nitrogen Purity Label on the control panel of the generator to determine the

proper dimensionless flow meter setting necessary to achieve the desired nitrogen purity.

Adjust the flow control valve on the control panel (see Figure 1) to yield the proper flow

meter reading.