70 - PVD 3663_GB_NX_March 2017.Docx

3.4.2.

Frame recommendation

Warning : The user has the entire responsibility to design and prepare

the support, the coupling device, shaft line alignment, and shaft line

balancing.

Foundation must be even, sufficiently rigid and shall be dimensioned in order to avoid

vibrations due to resonances.

The servomotors need a rigid support, machined and of good quality.

The maximum flatness of the support has to be lower than 0.05mm.

The motor vibration magnitudes in rms value are in accordance with IEC 60034-14

–

grade A:

maximum rms vibration velocity for NX is 1.3mm/s for rigid mounting

Warning : A grade A motor (according to IEC 60034-14) well-

balanced, may exhibit large vibrations when installed in-situ arising

from various causes, such as unsuitable foundations, reaction of the

driven motor, current ripple from the power supply, etc.

Vibration may also be caused by driving elements with a natural

oscillation frequency very close to the excitation due to the small

residual unbalance of the rotating masses of the motor.

In such cases, checks should be carried out not only on the machine,

but also on each element of the installation. (See ISO 10816-3).

Warning : A bad setting of the electronic control of the close loop

(gain too high, incorrect filtring …) can occur an instability of the shaft

line, vibration or/and breakdown - . Please consult us

Summary of Contents for NX Series

Page 1: ...1 PVD 3663_GB_NX_March 2017 Docx Servomotors NX Series Technical Manual PVD 3663...

Page 3: ...3 PVD 3663_GB_NX_March 2017 Docx Compliance with UL standards...

Page 4: ...4 PVD 3663_GB_NX_March 2017 Docx Compliance with UL standards...

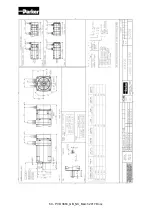

Page 39: ...39 PVD 3663_GB_NX_March 2017 Docx 3 3 Dimension drawings 3 3 1 NX1...

Page 40: ...40 PVD 3663_GB_NX_March 2017 Docx...

Page 41: ...41 PVD 3663_GB_NX_March 2017 Docx...

Page 42: ...42 PVD 3663_GB_NX_March 2017 Docx 3 3 2 NX1 UL version...

Page 43: ...43 PVD 3663_GB_NX_March 2017 Docx...

Page 44: ...44 PVD 3663_GB_NX_March 2017 Docx...

Page 45: ...45 PVD 3663_GB_NX_March 2017 Docx...

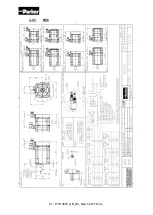

Page 46: ...46 PVD 3663_GB_NX_March 2017 Docx 3 3 3 NX2...

Page 47: ...47 PVD 3663_GB_NX_March 2017 Docx...

Page 48: ...48 PVD 3663_GB_NX_March 2017 Docx...

Page 49: ...49 PVD 3663_GB_NX_March 2017 Docx...

Page 50: ...50 PVD 3663_GB_NX_March 2017 Docx 3 3 4 NX2 UL version...

Page 51: ...51 PVD 3663_GB_NX_March 2017 Docx...

Page 52: ...52 PVD 3663_GB_NX_March 2017 Docx...

Page 53: ...53 PVD 3663_GB_NX_March 2017 Docx...

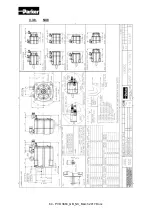

Page 54: ...54 PVD 3663_GB_NX_March 2017 Docx 3 3 5 NX3...

Page 55: ...55 PVD 3663_GB_NX_March 2017 Docx...

Page 56: ...56 PVD 3663_GB_NX_March 2017 Docx...

Page 57: ...57 PVD 3663_GB_NX_March 2017 Docx 3 3 6 NX4...

Page 58: ...58 PVD 3663_GB_NX_March 2017 Docx...

Page 59: ...59 PVD 3663_GB_NX_March 2017 Docx...

Page 60: ...60 PVD 3663_GB_NX_March 2017 Docx...

Page 61: ...61 PVD 3663_GB_NX_March 2017 Docx 3 3 7 NX6...

Page 62: ...62 PVD 3663_GB_NX_March 2017 Docx...

Page 63: ...63 PVD 3663_GB_NX_March 2017 Docx...

Page 64: ...64 PVD 3663_GB_NX_March 2017 Docx 3 3 8 NX8...

Page 65: ...65 PVD 3663_GB_NX_March 2017 Docx...

Page 66: ...66 PVD 3663_GB_NX_March 2017 Docx...

Page 67: ...67 PVD 3663_GB_NX_March 2017 Docx...

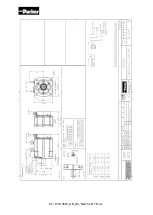

Page 68: ...68 PVD 3663_GB_NX_March 2017 Docx 3 3 9 NX8 water cooled...

Page 72: ...72 PVD 3663_GB_NX_March 2017 Docx 3 5 2 2 NX205 3 5 2 3 NX210...

Page 73: ...73 PVD 3663_GB_NX_March 2017 Docx 3 5 2 4 NX310 3 5 2 5 NX420...

Page 74: ...74 PVD 3663_GB_NX_March 2017 Docx 3 5 2 6 NX430 3 5 2 7 NX620...

Page 75: ...75 PVD 3663_GB_NX_March 2017 Docx 3 5 2 8 NX630 3 5 2 9 NX820...

Page 76: ...76 PVD 3663_GB_NX_March 2017 Docx 3 5 2 10 NX840 3 5 2 11 NX860...

Page 91: ...91 PVD 3663_GB_NX_March 2017 Docx 3 8 4 Mains supply connection diagrams...

Page 92: ...92 PVD 3663_GB_NX_March 2017 Docx...

Page 93: ...93 PVD 3663_GB_NX_March 2017 Docx...

Page 94: ...94 PVD 3663_GB_NX_March 2017 Docx...

Page 95: ...95 PVD 3663_GB_NX_March 2017 Docx...

Page 96: ...96 PVD 3663_GB_NX_March 2017 Docx...