19

EN

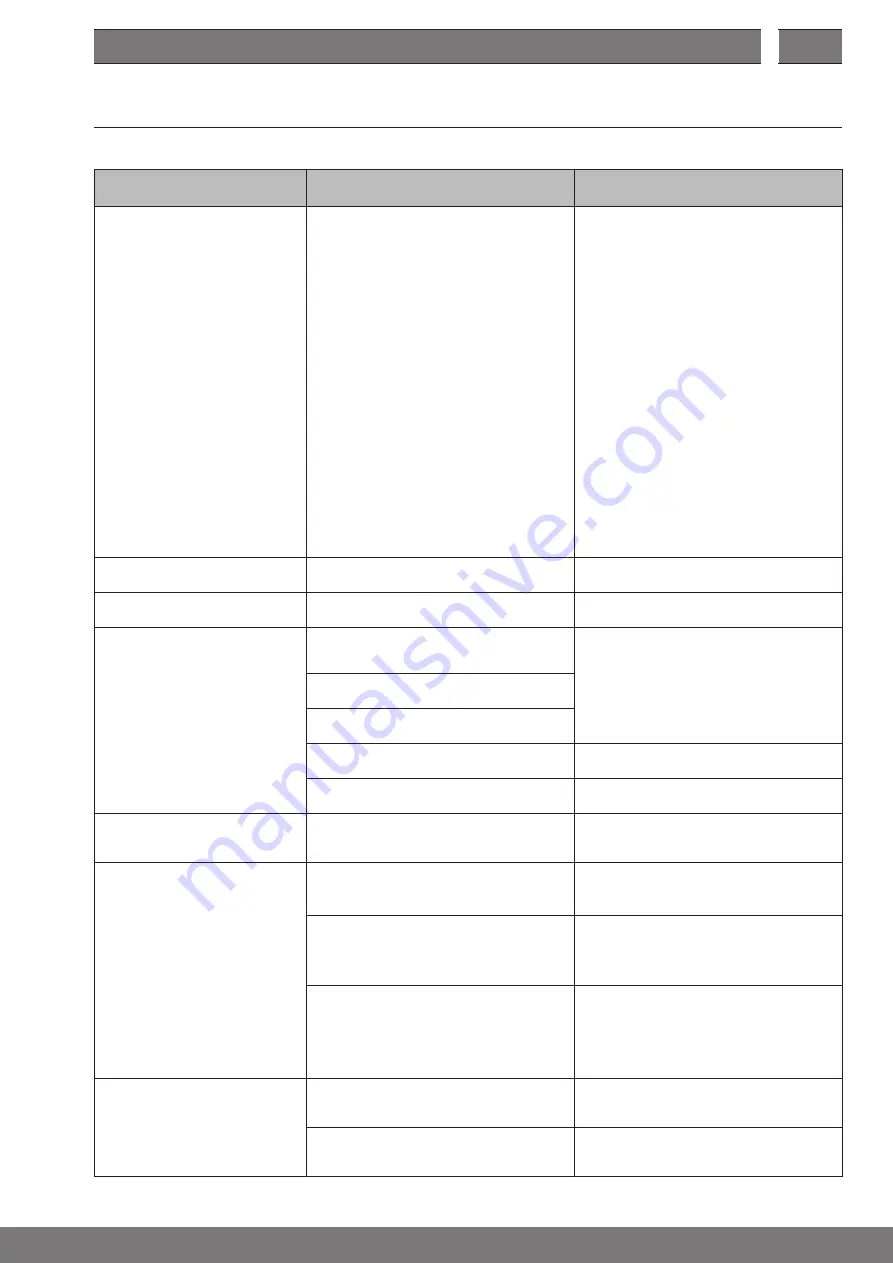

12 Trouble shooting

List of faults

Fault description

Possible cause

Remedy

Heavy leakage.

Inner sealing band pressed/sucked in.

Clamp the sealing band:

- Remove the clamp caps (12) on both sides.

- Remove clamping screws (13) and (15) on

both sides.

- Push the piston to an end position.

- Lift the A-Band on the long side.

- Carefully push the inner sealing band on the

long side to the inside for the entire length

using an object that does not have sharp edges.

- On the side where the piston is located, push

the clamping piece (16) lightly to the outside

and tighten the clamping screws (15).

- Push the clamping piece as far as possible to

the outside on the opposite side until the sealing

band either fits on the cylinder barrel or the

clamping piece fits on the cushioning spigots.

- Tighten the clamping screw (15).

- Mount A-Band.

- Move the piston by hand for two strokes and

bring to around the centre of the stroke.

- Arrange the A-Band and tighten the clamping

screws (13).

- Mount the clamp caps.

Cylinder leaks at the piston.

Piston seal defective (24).

Replace piston seal.

Cylinder leaks at the end cap.

O-ring (18, 19, 21) defective.

Replace O-rings.

Piston moves slowly or jerking.

Contamination by air or abrasion.

Completely disassemble, clean and grease cyl-

inder. Replace wearing parts (see wearing parts

list on page 21).

Poor lubrication.

Piston seal (24) defective.

Incorrect adjustment of speed (too slow).

Increase speed.

Operating pressure below 2 bar.

Check operating pressure.

Piston does not reach the end posi-

tion.

Cushioning adjustment screw screwed in at the

end cap.

Adjust cushioning adjustment screw at the end

cap.

Cylinder impacts too hard at one or

both end positions.

Incorrect adjustment of end cushioning.

Alter adjustment of cushioning adjustment

screw.

Possibly overload.

Install additional shock-absorbers, see admis-

sible weights and speeds in cushioning diagram

of OSP-L catalogue.

Cushioning seal (23),

O-rings at endcap (18, 19),

cushion spigot (21),

piston seal (24) or

inner sealing band (17) defective.

Check parts and replace if necessary.

The magnetic switch is defective.

There are ferritic parts too close to the magnetic

switch

Use parts on non-magnetic material.

Magnetic switch defective.

Replace magnetic switch

(see catalogue OSP-L).