19

20

Parker Hannifin Corporation

|

Pump & Motor Division

|

Kings Mountain, NC

Parker Hannifin Corporation

|

Pump & Motor Division

|

Kings Mountain, NC

WARNING:

This product can expose you to chemicals including lead or DEHP which are known to the state of California to cause cancer,

birth defects, and other reproductive harm. www.p65warnings.ca.gov

WARNING:

This product can expose you to chemicals including lead or DEHP which are known to the state of California to cause cancer,

birth defects, and other reproductive harm. www.p65warnings.ca.gov

Catalog HY13-PMD500-SM/US

PGP/PGM 500 Series

Gear Pumps & Motors Service Manual

Fluid Recommendations

When choosing your Hydraulic Oil, duty cycle and oil

temperature must be factored in to optimize your system

performance. Since hydraulic systems often work under

extreme temperature changes, especially in moderate to

severe duty cycles, the lubrication qualities of the oil in tight

tolerance components is even more critical.

Viscosity choice is always a compromise; the fluid must

be thin enough to flow easily but thick enough to seal and

maintain a lubricating film between bearing and sealing

surfaces. This film of oil helps to reduce friction and heat,

which can ultimately lead to component damage.

Fluid temperature does affect viscosity. When choosing a

fluid, it is important to consider the start-up and operating

temperatures of the hydraulic system In general, as the

fluid warms, it gets thinner and its viscosity decreases. At

the highest temperatures, the fluid must be thick enough

to provide lubrication and minimize internal leakage. Low

viscosity leads to the following problems:

• Higher leakage across all sealing gaps in the pump

leading to lower volumetric efficiencies and heat.

• Heat will cause loss of lubrication and will create

severe wear because of metal to metal contact,

causing premature failure of the gears, thrust plates

and bushing blocks.

The opposite is true when the fluid cools, its viscosity

increases. At the lowest temperatures, the fluid must be

thin enough to flow readily. High viscosity oil leads to the

following problems:

• Sealing and lubrication gaps not being filled, loss of

lubrication

• Filling losses occur which causes cavitation damage to

the pump

Under normal operating temperatures it is recommended

to keep the temperature of the hydraulic fluid in the range

of 120°F to 140°F (49°C to 60°C). Fluids may break down

or oxidize at high temperatures, which leads to varnish or

sludge deposits in the system and also reduces lubricity

and results in reduced life of the unit. As a rule of thumb,

operating temperatures over 176°F (80°C) reduce the

service life by half for every 50°F (10°C) temperature

increase, and should be avoided.

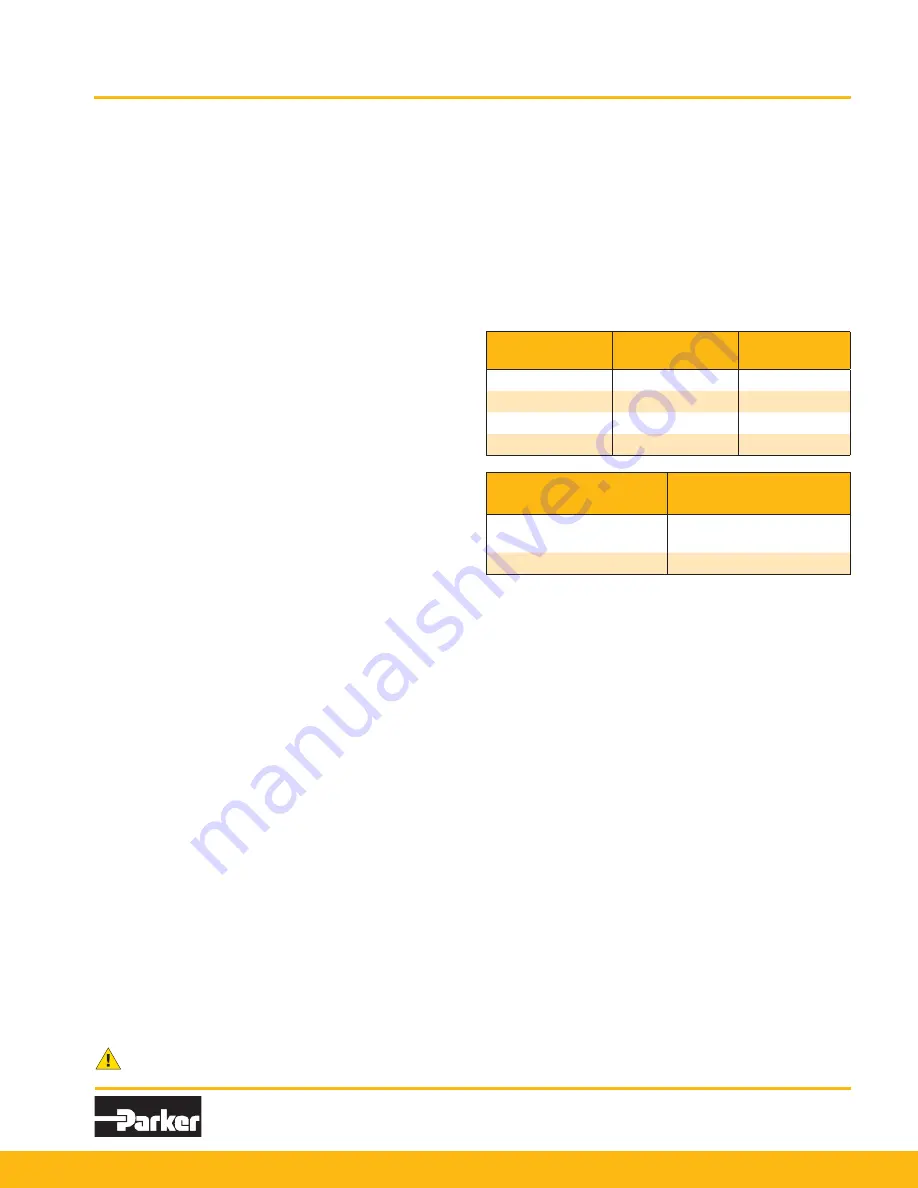

Petroleum Oils (Mineral-based)

Viscosity Recommendations

Optimum operating viscosity is considered to be about

100 SUS (20 cSt).

Minimum approximately: 50 - 60 SUS (7.5 - 10 cSt)

Maximum at start up approximately: 7500 SUS (1600 cSt)

Recommended Viscosity Grades:

Grade

Viscosity at

100°F (40°C)

Viscosity at

210°F (100°C)

ISO 32

165 SUS (32 cSt)

44 SUS (5 cSt)

ISO 46

240 SUS (46 cSt)

49 SUS (7 cSt)

SAE 10

150 SUS (32 cSt)

41 SUS (4 cSt)

SAE 20

300 SUS (71 cSt)

51 SUS (7 cSt)

Other Desirable

Properties

Additives Usually

Recommended:

Viscosity Index:

90 minimum

Rust and Oxidation (R & O)

Inhibitors

Aniline Point: 175 minimum

Foam Depressant

NOTE:

Antiwear (AW) additives are not necessarily

recommended. In some instances the presence of zinc

compounds can actually be harmful to copper, bronze, or

brass components used in the system. The use of AW oil is

optional with our gear units.

General Recommendations

High quality hydraulic oils are essential for satisfactory

performance and long life of any hydraulic system. Such

oils are usually prepared from highly refined, turbine oil

stocks with which select additives are compounded. We

suggest following the manufacturer's specifications or the

recommendations of a reputable oil supplier for the specific

oil requirements on your machine.

A high viscosity oil will generally give better performance

and life than a thin oil. Oil of around 100 SUS (20 cSt) will

give optimum performance. Your selection should be as

near to optimum as possible at operating temperature but

not so heavy at start-up as to cause cavitation. Cold start-

up procedures which allow the use of heavier oils should

prove worthwhile by increasing pump life. The oil must be

clean and contain less than 0.1% water.

Hydraulic Oil Recommendations