Variable displacement pump

Series VP1-045 / -075

Bulletin HY30-8222-INST/UK

Installation information

3

Parker Hannifin

Pump & Motor Division Europe

Trollhättan, Sweden

The VP1 input shaft must

not

be subject to

external radial and/or axial forces (see

illustration to the right).

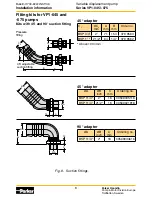

Installation examples:

a)

A gear drive with a bearing supported

gear is acceptable (as shown in the illus-

tration below)

b)

A gear mounted directly on the VP1 input

shaft is usually

not

acceptable

c)

A belt drive pulley installed directly on

the VP1 input shaft is usually

not

allowed

Fig. 3. Usually, no external radial and/or

axial forces are allowed on the VP1 shaft

VP1 installation on a PTO /engine PTO

NOTE

:

If an installation according to

b) or c) above, is considered,

contact Parker Hannifin.

VP1_to_PTO_install_09-02-12.ai

Leif A.

Fig. 4. VP1-045/075 shown with a bearing supported gear on an engine PTO adapter

(example).

VP1-045/075_no_shaft_loads.ai

Leif A./11-02-04