7

The supply voltage and FLA will be noted on the nameplate. The

blower and pulse cleaning system controls are factory pre-wired

for operation. The touchscreen controls are also pre-wired for the

integral option, but require field wiring and connections for the

remote display enclosure option. Wiring diagrams for the various

SHM controls, blower arrangement and supply voltage options are

available within the appendix of this manual. Note that the SHM

does not contain the main disconnect or fuses for the supply power.

Electrical installation should be completed by a qualified professional

and done in accordance with all applicable codes and regulations.

Power cord and connection into unit will be supplied by the cus-

tomer.

Unit is available in the voltages shown below:

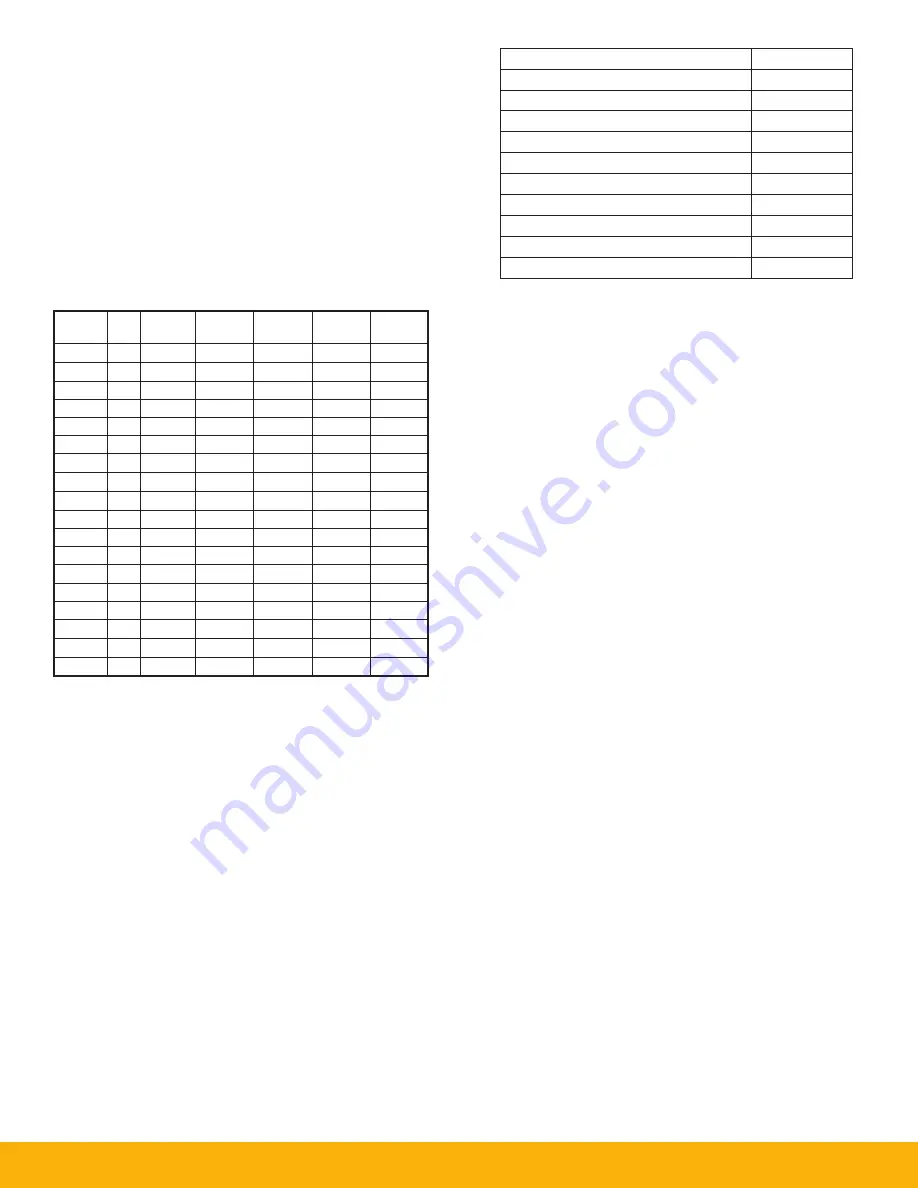

TABLE 1

SHM Voltage and Full Load Amps

Note: When making the main power connections to the unit,

fan rotation check is not required.

3.5.1 Electrical Power Supply

The main power supply is connected to the SHM unit through a 1˝

FNPT coupling located on the rear of the unit shown in Figure 1B.

After feeding wires through the coupling, terminations are made on

the main bus bar terminal for each phase and frame ground con-

nection. The rear electrical panel also contains the unit circuit break-

ers and DC power supply for the controls components. Utilize Table

1 for wire, fuse and disconnect sizing for your respective product

model. A second plugged 1˝ FNPT coupling is also located on the

rear of the cabinet for low optional voltage connections using the

Machine Interlock feature to automate operation. Ensure that the

rear electrical panel cover is in place and secured prior to operating

the unit. Refer to the electrical wiring diagrams in Table 2 for addi-

tional wiring information.

3.5.2 Electrical Basic Controls

The basic electrical controls consist of a thermal motor protec-

tion disconnect on the side of the unit. This is set for the FLA of

the single blower motor. This is factory prewired to the blower

motor. When installing this unit in the field the customer will con-

nect their factory power to the disconnect on the line side of the

thermal protector. The disconnect On/Off will supply power to

the unit and allow the blower On/Off switch on the front of the

unit to control the blower. Inside the door on the front of the unit

there is a blower speed adjustment. This will control the speed

of the blower from off to full speed. This should be adjusted by

the customer to meet their process requirements.

3.5.3 Electrical Touchscreen Controls

The main control panel for the SHM unit is a touchscreen interface

located integrally on the front of the unit or remotely in an auxiliary

enclosure (refer to section 3.5.4) that operates the blower.

The touchscreen control panel is powered by 24V DC. Refer to

Section 4 of this manual for operation of the touchscreen. All wir-

ing in the touchscreen controls panel is pre-wired at the factory

and there are no customer connections at this panel. The panel

door should remain closed and locked during operation.

3.5.4 Electrical Remote Panel Controls

Both the Basic and Touchscreen Controls can be mounted

remotely from the unit. The max distance is 100 FT (30.5 m).

The controls are provided in a NEMA 4X enclosure for mounting.

VOLT

PH

#

BLWR

HZ

RPM

FLA

XFMR

208

3

1

50-60

3370

6.5

---

230

3

1

50-60

3370

5.7

---

240

3

1

50-60

3370

5.5

---

380

3

1

50-60

4200

6.7

---

480

3

1

50-60

4200

5.5

---

575

3

1

50-60

4200

---

6kVA

208

3

2

50-60

3370

13.5

---

230

3

2

50-60

3370

11.5

---

240

3

2

50-60

3370

11.0

---

380

3

2

50-60

4200

13.9

---

480

3

2

50-60

4200

11.0

---

575

3

2

50-60

4200

---

10kVA

208

3

3

50-60

3370

18.9

---

230

3

3

50-60

3370

16.4

---

240

3

3

50-60

3370

15.5

---

380

3

3

50-60

4200

19.1

---

480

3

3

50-60

4200

15.5

---

575

3

3

50-60

4200

---

15kVA

FOR BASIC CONTROLS ON SHM-11, SUBTRACT

0.5 AMP FROM FLA VALUES ABOVE.

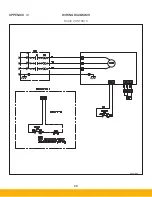

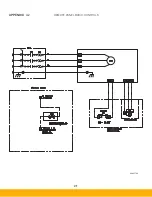

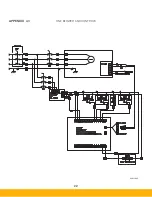

Descripon of Wire Diagram

Appendix

Basic Controls

A1

Remote Panel Basic Controls

A2

One Blower & Controls

A3

Two Blower & Controls

A4

Three Blower & Controls

A5

Remote Panel Touch Controls

A6

One Blower & Remote Controls

A7

Two Blower & Remote Controls

A8

Three Blower & Remote Controls

A9

Transformer 575:480

A10

TABLE 2

Wire Diagrams

Summary of Contents for SmogHog SHM-C

Page 1: ...SMOG HOG Media Mist Collector Owner s Manual Models SHM C SHM F...

Page 6: ...Page intentionally left blank...

Page 8: ...4 FIGURE 1B SHM Equipment Description 61 10113 FIGURE 1A SHM Equipment Description...

Page 13: ...9 61 10126 FIGURE 4 Remote Panel Touchscreen Connection...

Page 23: ...19 Figure 6 SHM Replacement Parts SHM 11C SHM 11F...

Page 24: ...20 APPENDIX A1 WIRING DIAGRAMS BASIC CONTROLS 04 001682...

Page 25: ...21 REMOTE PANEL BASIC CONTROLS 04 001799 APPENDIX A2...

Page 26: ...22 ONE BLOWER AND CONTROLS 04 001695 APPENDIX A3...

Page 27: ...23 TWO BLOWER AND CONTROLS 04 001696 APPENDIX A4...

Page 28: ...24 THREE BLOWER AND CONTROLS 04 001697 APPENDIX A5...

Page 29: ...25 REMOTE PANEL TOUCH CONTROLS 04 001802 APPENDIX A6...

Page 30: ...26 ONE BLOWER AND REMOTE CONTROLS 04 001798 APPENDIX A7...

Page 31: ...27 TWO BLOWER AND REMOTE CONTROLS 04 001797 APPENDIX A8...

Page 32: ...28 THREE BLOWER AND REMOTE CONTROLS 04 001796 APPENDIX A9...

Page 33: ...29 575 480 TRANSFORMER 04 001717 APPENDIX A10...

Page 36: ...32...

Page 37: ...33...