8

Basic Controls – The remote controls panel/enclosure will

contain the blower speed adjusting potentiometer inside the

enclosure, and an on/off switch on the cover. This enclosure

will be attached to the SHM unit at the factory with 50ft of wire.

The cable can be cut down in length at the time of installation if

needed by disconnecting the wire from the remote panel, cut-

ting to length, and reconnecting. Use the wire diagram on page

A2 for reference.

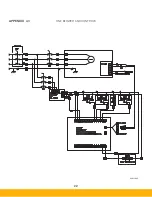

Touchscreen Controls – The remote touchscreen controls

enclosure will contain the touchscreen and terminal blocks for

the wire connections. There are two cables connected to the

remote enclosure that are 100ft each. One is the 24 VDC power

supply and control cable, and the other is a communication

cable. These wires will need to be connected to the rear control

panel of the SHM unit by the customer at the time of installation.

The first wire is the low voltage controls wire that will connect

to the terminal blocks in the back of the SHM unit on +24VDC,

-24VDC, AN2, AN3, AN4, I0, and O0. Use the wire diagram on

page A6 for wire colors and terminal location for landing. The

second wire is a communication wire that needs landed in the

WAGO 222 Lever Wall Nuts. Match the colors of the wires,

brown with brown and black with black.

3.5.5 Machine Interlock Dry Contact

The customer has the option to control the SHM On/Off oper-

ation with the oil mist generating equipment or process. This

will allow the operator to control the SHM with a dry-contact

off another piece of equipment. Refer to the wiring diagrams

in the appendix for wiring of this option and to Section 4 for

Machine Interlock set up on the touchscreen.

Wiring will be terminated to the terminal blocks located in

the rear electrical panel in Figure 1B. When the machine dry

contact is closed, the SHM blower will be on and when the

contact is open, the SHM unit blower will shut down.

Note: A relay coil cannot be connected to the SHM and will

not work for this type of electrical circuit.

3.6 Filter Installation

The primary filter elements are shipped already installed in the

SHM unit. If an after-filter option is selected by the customer,

those filters will be shipped separate of the unit to be mounted

following unit installation at the customer facility. Filters may

removed from the primary filter cabinet by the customer when

delivered to lessen weight, protect them from damage, and ease

unit installation.

Proper removal and installation of each filter type is shown in

figures 5A & 5B.

3.6.1 Installation Procedure for After-Filters

3.6.1.1 Hold Down

Center the filter(s) atop the unit when viewed from the front. If the

unit is two filters deep, then the two after-filters will be butted against

each other in the center of the unit (looking at it from the side) from

front to back just as with the internal filters.

The hold-down brackets are to be placed on top the filters as

shown in Figure 5A balloon #7 and secured down with all-thread

rods, washers and nuts. Tighten nuts using hand tools and be sure

not to over compress the gasket on the bottom side of the after-

filter. Minimal torque should be applied; just enough to cinch down

each bracket so it will not slide around on top of the filter(s). On

units two filters deep, a center bracket is also supplied that runs in

the same direction, it is placed immediately over the seam where

the two filters are butted together.

Larger size unit after-filter setups will be installed in an identical

fashion. The filters will always be installed in-line, directly over the

perforated square cutouts on the top panel.

3.6.1.2 Enclosure

For units with an after-filter cabinet/enclosure, the after-filters must

be installed into this cabinet. The box-shaped after-filter slides into

the cabinet door on the cam-bars. Be sure the filter(s) is pushed all

the way to the back of the cabinet where it will bottom out on a stop.

Rotate the cam-bars upward as illustrated in figure 5B. This will seal

the filter’s top mounted gasket onto the cabinet’s upper tube sheet.

3.7 Drains

All SHM units are supplied with 1-1⁄2˝ FPT drain connections. Use

a 1-1⁄2˝ drain trap or similar to prevent air from being sucked up

through the drain when unit is running.

NOTES: Main drain line should be sufficiently sloped and vented. All

plumbing should conform with all state and local codes.

Appropriate design criteria as provided by a plumb-

ing/mechanical contractor should be utilized to

ensure proper control of drainage from the SHM

Unit.

C A U T I O N

Summary of Contents for SmogHog SHM-C

Page 1: ...SMOG HOG Media Mist Collector Owner s Manual Models SHM C SHM F...

Page 6: ...Page intentionally left blank...

Page 8: ...4 FIGURE 1B SHM Equipment Description 61 10113 FIGURE 1A SHM Equipment Description...

Page 13: ...9 61 10126 FIGURE 4 Remote Panel Touchscreen Connection...

Page 23: ...19 Figure 6 SHM Replacement Parts SHM 11C SHM 11F...

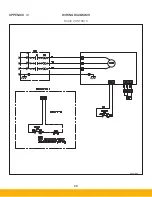

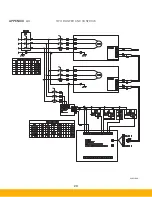

Page 24: ...20 APPENDIX A1 WIRING DIAGRAMS BASIC CONTROLS 04 001682...

Page 25: ...21 REMOTE PANEL BASIC CONTROLS 04 001799 APPENDIX A2...

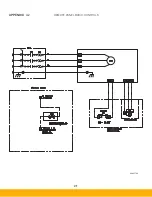

Page 26: ...22 ONE BLOWER AND CONTROLS 04 001695 APPENDIX A3...

Page 27: ...23 TWO BLOWER AND CONTROLS 04 001696 APPENDIX A4...

Page 28: ...24 THREE BLOWER AND CONTROLS 04 001697 APPENDIX A5...

Page 29: ...25 REMOTE PANEL TOUCH CONTROLS 04 001802 APPENDIX A6...

Page 30: ...26 ONE BLOWER AND REMOTE CONTROLS 04 001798 APPENDIX A7...

Page 31: ...27 TWO BLOWER AND REMOTE CONTROLS 04 001797 APPENDIX A8...

Page 32: ...28 THREE BLOWER AND REMOTE CONTROLS 04 001796 APPENDIX A9...

Page 33: ...29 575 480 TRANSFORMER 04 001717 APPENDIX A10...

Page 36: ...32...

Page 37: ...33...