Page 2

/ Bulletin 100-50-1

LEGEND

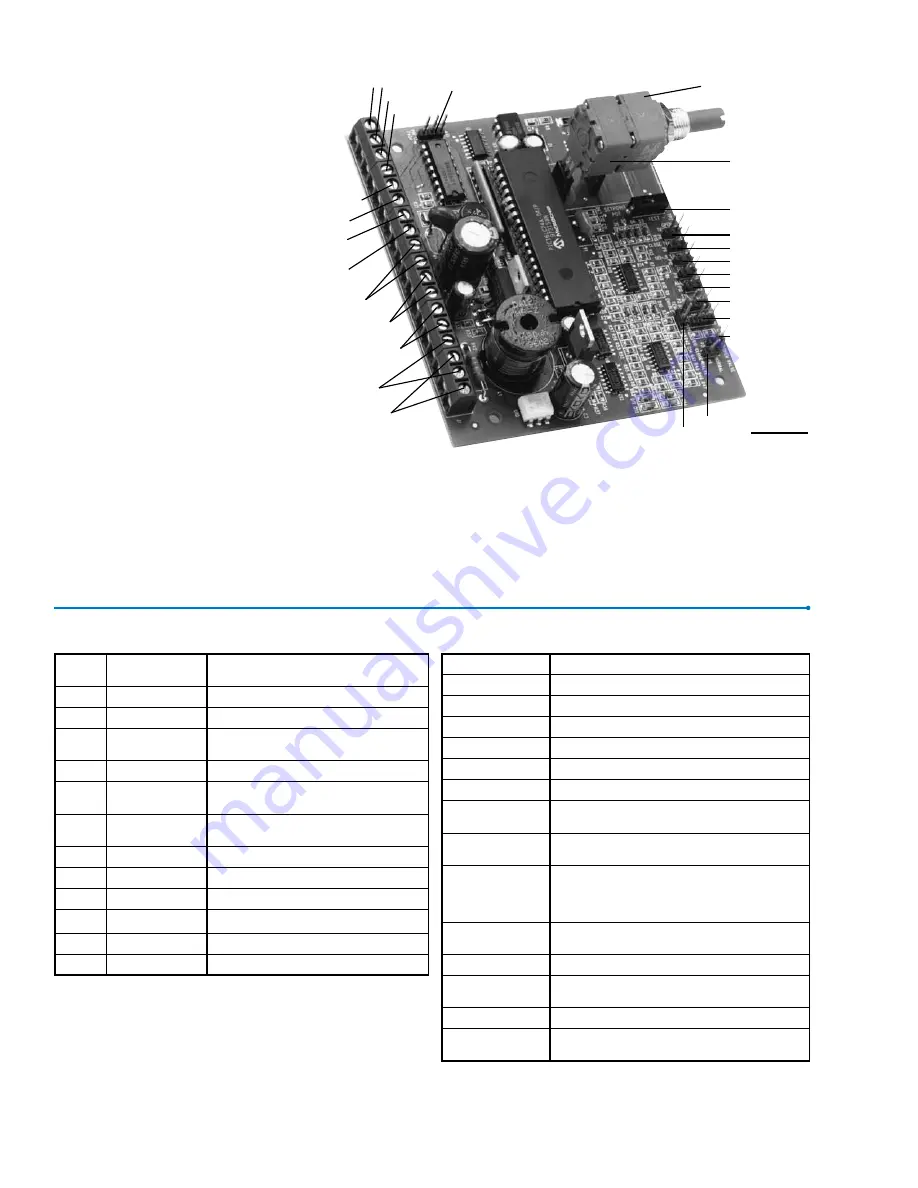

TEST POINTS and PIN JUMPERS

TP1

Test Point 1

positive connection point to millivolt voltmeter to

read set point temperature

TP2

Test Point 2

negative connection point as above

P1

Pin Jumper 1

voltage or current input selector

P2

Pin Jumper 2

TTL logic or 24-120 VAC Pulse Width Modulated

signal input selector

P4

Pin Jumper 4

internal power selector - DO NOT CHANGE

P5

Pin Jumper 5

force valve open switch - valve will open and will

remain open as long as jumper is installed

P6

Pin Jumper 6

force valve closes switch - valve will close and

remain closed while jumper is installed

P7

Pin Jumper 7

temperature sensor enable selector

P8

Pin Jumper 8

“open on rise” logic selector

P9

Pin Jumper 9

“close on rise” logic selector

P10

Pin Jumper 10

SEI .5 to SEI-11 valve selector (1596 step stroke)

P11

Pin Jumper 11

CDS-8 valve selector (3193 step stroke)

P12

Pin Jumper 12

all other valves selector (6386 step stroke)

WIRING CONNECTIONS

PID+

connect positive side of 4-20 ma or 0-10 VDC signal

INPUT

connect negative side of 4-20 ma or 0-10 VDC signal

BLACK

connect black valve lead

WHITE

connect white valve lead

GREEN

connect green valve lead

RED

connect red valve lead

Square Wave

connect TTL logic (5 VDC) step signal

DIRECTION

connect TTL logic direction signal. 5 VDC = OPEN, 0 VDC

= CLOSE

24 VAC

2 connections for 24 VAC or 24 VDC @ 40 VA isolated

power input

PUMPDOWN

2 connections for pumpdown contacts. When “shorted”

the valve will close and remain closed. When “open” the

valve will control normally. For alternate operation see

5.

under “Wire the Board” pg 3.

TEMP SENSOR

2 connections for supplied 2 k type B thermistor. Not

polarized.

Blank

no connection - for high voltage input isolation.

AC PULSE

for one leg of 24-120 VAC, 3-30 second Pulse Width

Modulated signal.

Blank

no connection - for high voltage input isolation.

AC PULSE

for the other leg of 24-120 VAC, 3-30 second Pulse Width

Modulated signal.

NOTE:

Not all inputs or pin jumpers will be used. See Configuration

instructions.

Valves of any capacity except 2500 step

valves such as CDST-4 & CDST-7 (see note

on page 2). Pin jumpers on the face of the

board will permit changes in board control

parameters to suit particular applications.

Figure 1 shows the layout of the board with

connection points labeled.

Figure

1

P6

P5

P1

P2

P12

P11

P10

P9

P8

TP2

Set Point

Potentiometer

TP1

P7

24-120 VAC

PWM Pulse

No Conn.

Temp. Sensor

Pumpdown

24VAC

TTL

Direct.

TTL

Wave

Red

Green

PID+

PID-

Black

White

P4

The Sporlan TCB has been developed to

allow the control of most Sporlan electric

valves with the use of a generic PID or

similar controller, or with the addition of the

Sporlan sensor, to perform as a stand alone

temperature controller. In addition to the 0

to 10 volt DC or 4 to 20 milliamps signal

usual from PID controllers, the TCB can be

configured to modulate a valve in response

to a TTL (5 volt) signal, or a 24-120 volt

AC pulse of three to thirty seconds duration.

The

TCB

may be ordered less potentiometer

if an external signal (e.g. 4-20ma) is to be

used. See ordering instructions. The board

was designed for easy standoff mounting

in electrical panels supplied by others, and

with screw terminal wiring connections.

The unit is small (3.5” x 4.0”) and eco-

nomical and requires only 24 volts AC or

24 VDC at 40 VA for both board and valve

power. Operating ambient and storage tem-

perature is -10°F to 160°F.

The

TCB

has been designed to work with

Sporlan SEI/SEH Electric Expansion

Valves, CDS Electric Suction Control

Valves, and SDR Electric Hot Gas Bypass

FOR USE ON REFRIGERATION and/or AIR CONDITIONING SYSTEMS ONLY

Bulletin 100-50-1, December 2010 supersedes Bulletin 100-50-1, January 2006 and all prior publications.