5

HOOD ADJUSTMENT

1. The hood can be adjusted to change the deflection

of the material being handled by loosening the wing

nuts on both sides of the hood and sliding the hood

up or down (figure 3).

2. If sweeping at a high rate of speed, the hood should

be raised to deflect the material to the back of the

basket.

3. If sweeping at a low rate of speed, the hood should

be lowered until material goes to the back of the

basket.

BRUSH CARE AND REPLACEMENT

Brush Removal

Never allow the brush bristles to remain in a bent position

on any object for any length of time as they can take a

set. Should the bristles take a set from use, reverse the

brushes on the reel shaft as follows:

1. Turn the sweeper upside down on a workbench or

the ground.

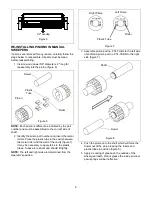

2. The brush stud has a collar fitting against one of the

brush brackets holding it against the reel shaft

(figure 4).

3. Remove the speed nuts and brush clamps from the

end of the studs on the sides with the collar.

4. Remove the brushes from the brush bracket slots.

5. Remove the speed nuts and brush clamps from the

opposite end of the studs. DO NOT remove the

speed nut or the stud will fall out of reel shaft

releasing the brush brackets.

Brush Installation

1. Turn the reel shaft to position the brush strips in the

slots of the brush brackets held on the stud by the

speed nut (figure 4).

2. Position the brush clamps and finger tighten nuts.

Be sure brushes are all the way down in all the

brush brackets.

3. Brushes will be staggered with a slight overlap

(figure 5). Tighten lock nuts to ensure brushes are

held firmly in place.

4. Turn the reel shaft so the installed brush strips are

on the bottom.

5. Repeat steps 1 – 4 for the remaining brushes.

6. Tighten all nuts. Torque to 4.2 – 4.6 lb.ft (61 – 67

N-m).

LUBRICATION

1. Occasional lubrication of the sweeper will lengthen

the service life.

2. Check grease in wheels before operating unit. Each

wheel has a grease fitting in the hub near the axle.

Add grease until grease is forced out through gap of

hub at axle.

3. Place a few drops of oil in the swivel bearings and

axle of the casters every time the machine is used.

Figure 3

MAINTENANCE

Figure 4

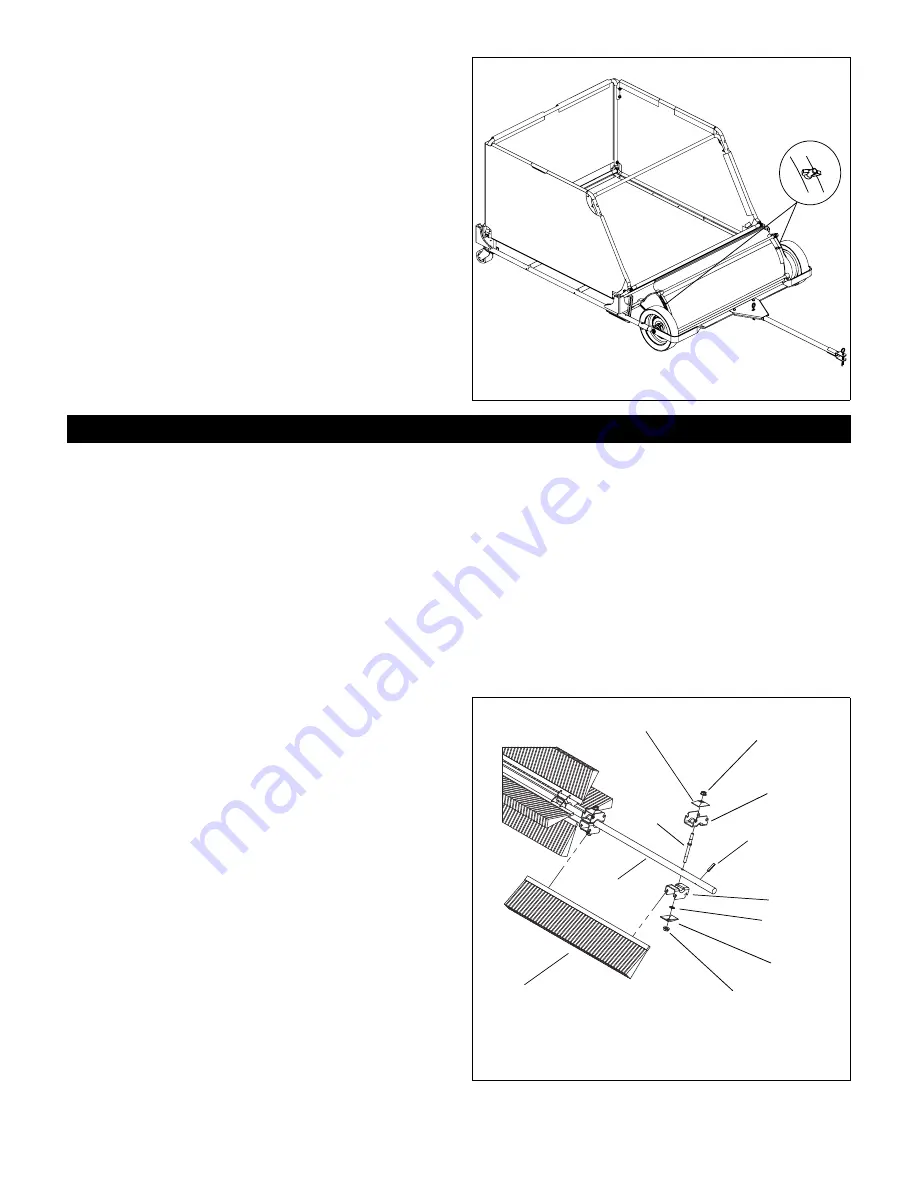

Brush

Clamp

Reel Shaft

Brush

Bracket

1/4 Speed

Nut

Clamp

Stud

Collar

Serrated

Flange Nut

Brush

Bracket

Roll Pin

Serrated

Flange Nut