124 - PVD 3622_GB_TM_January 2014.Docx

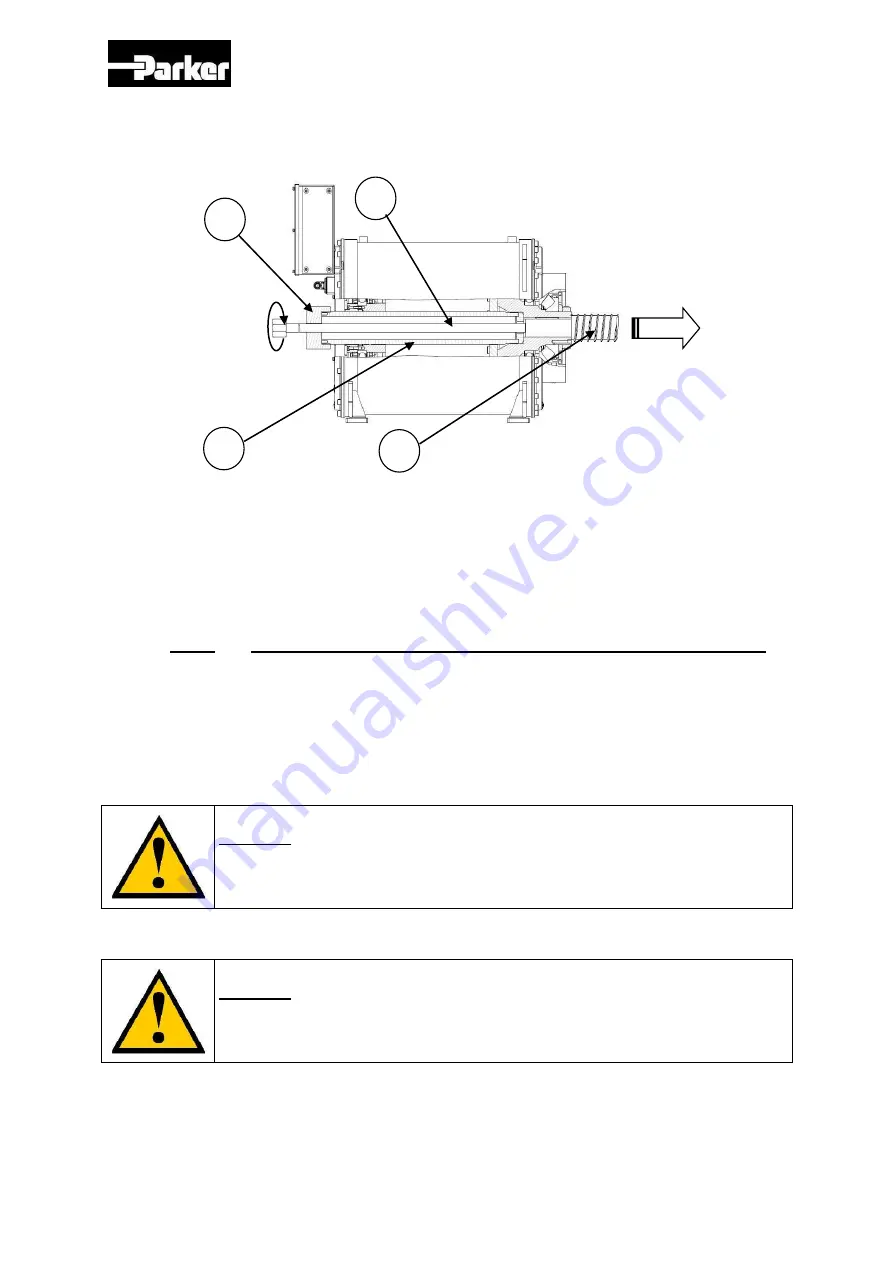

The drawing below shows how to remove the screw from the front of the motor when

the motor is equipped with a screw cooling protection pipe.

Having removed the screw cooling conduit, mount the screw extraction mechanical

part (1) at the end of the protection pipe (2), using the threading intended for this

operation. Then insert a threaded steel rod (3) from the rear of the motor. Rotate the

threaded steel rod until it reaches the extrusion screw (4). Continue to rotate the rod

in order to push the screw out of the front of the motor.

4.5.3.

Rear side screw extraction with screw cooling (Execution R)

In execution R, torque motors are equipped with a patent pending mechanism

allowing the extraction of the extrusion screw from the rear of the motor. An internal

sealed protection pipe also allows the passage of an external water conduit for the

cooling of the extrusion screw through the motor.

Warning: The protection pipe is only intended to isolate the motor in

case of coolant leakage. It shall not be used directly as a coolant

conduit. Use an external system to convey the coolant to the screw.

Warning: When removing the extrusion screw from the rear of the

motor, the extrusion screw has to be clean to avoid material deposit

inside the motor.

1

2

4

3

Summary of Contents for TM Series

Page 1: ...1 PVD 3622_GB_TM_January 2014 Docx Torque Motors TM Series Technical Manual PVD 3622...

Page 57: ...57 PVD 3622_GB_TM_January 2014 Docx 3 3 1 2 Shaft Height 200 mm Thrust bearing 29424...

Page 61: ...61 PVD 3622_GB_TM_January 2014 Docx 3 3 2 2 Shaft Height 315 mm Thrust Bearing 29426...

Page 62: ...62 PVD 3622_GB_TM_January 2014 Docx 3 3 2 3 Shaft Height 315 mm Thrust Bearing 29430...

Page 66: ...66 PVD 3622_GB_TM_January 2014 Docx 3 3 3 2 Shaft Height 400 mm Thrust Bearing 29434...

Page 67: ...67 PVD 3622_GB_TM_January 2014 Docx 3 3 3 3 Shaft Height 400 mm Thrust Bearing 29440...