HY13-1526-001-M1/US

Torqmotor™ Service Procedure

TC, TS, TB, TE and TJ Series

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 US

35

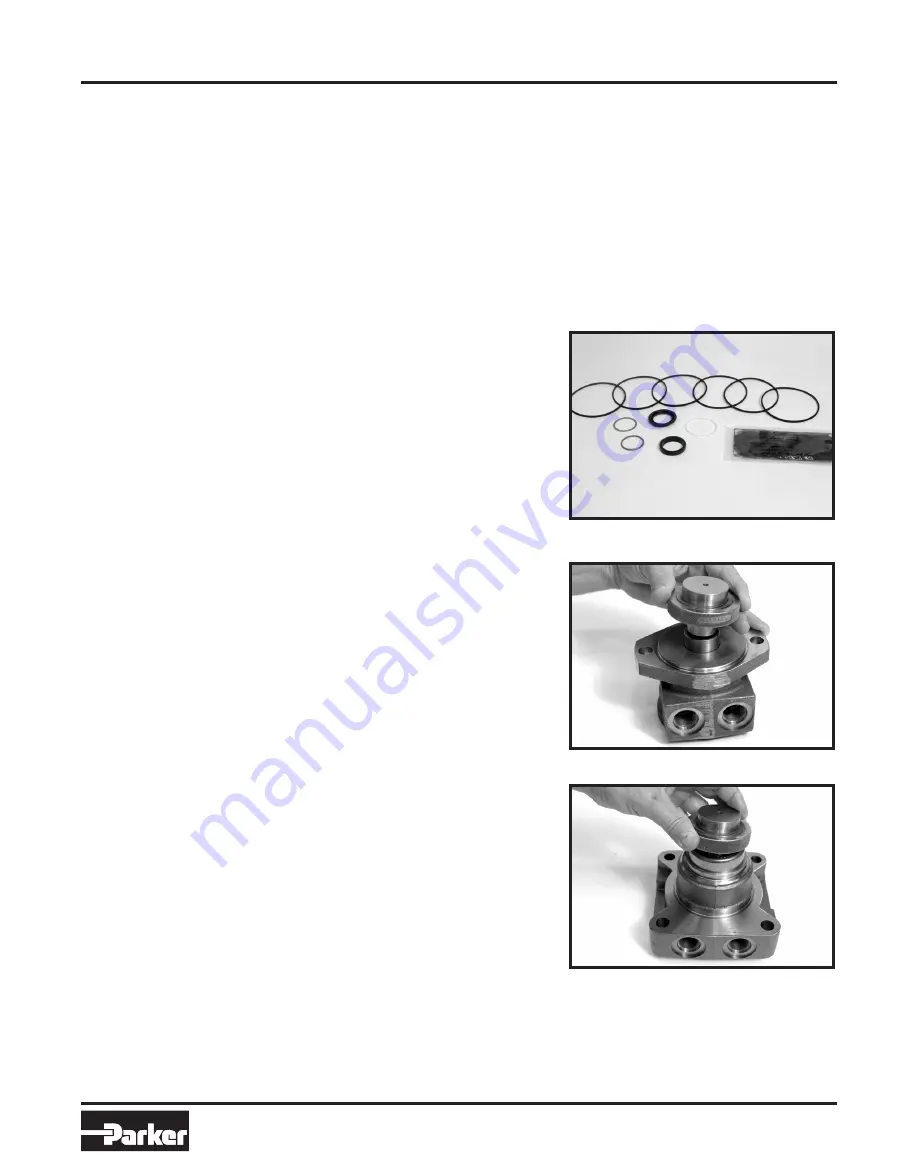

• Replace all seals and seal rings with new ones each time you reassemble the Torqmotor™ unit. Lubricate all

seals and seal rings with SAE 10W40 oil or clean grease before assembly.

• NOTE: Individual seals and seal rings as well as a complete seal kit are available. SEE FIGURE 35.

The parts should be available through most OEM parts distributors or Parker approved Torqmotor™

distributors. (Contact your local dealer for availability).

•

NOTE: Unless otherwise indicated, do not oil or grease parts before assembly.

• Wash all parts in clean petroleum-based solvents before assembly. Blow them dry with compressed air. Re-

move any paint chips from mating surfaces of the end cover, commutator set, manifold rotor set, wear plate

and housing and from port and sealing areas.

WARNING

WARNING

WARNING: SINCE THEY ARE FLAMMA-

BLE, BE EXTREMELY CAREFUL WHEN

USING ANY SOLVENT. EVEN A SMALL

EXPLOSION OR FIRE COULD CAUSE

INJURY OR DEATH.

WARNING: WEAR EYE PROTECTION

AND BE SURE TO COMPLY WITH OSHA

OR OTHER MAXIMUM AIR PRESSURE

REQUIREMENTS.

Press in outer

bearing/bushing

1. If the housing (17) bearing components were

removed for replacement, thoroughly coat and

pack a

new

outer bearing/bushing (18) with

clean corrosion resistant grease recommended

in the material section. Press the new bearing/

bushing into the counterbore at the mounting

flange end of the housing, using the appropri-

ate sized bearing mandrel such as described in

Figure 1 or Figure 2 which will control the bear-

ing/ bushing depth.

TC, TS, TB and TE Torqmotor™ housings

require the use of bearing mandrel shown in

Figure 1 to press bearing/ bushing (18) into the

housing to a required depth of .151/.161 inches

(3.84/4.09 mm) from the end of the bearing

counterbore. SEE FIGURE 36A.

TJ Torqmotor™ housings require the use of

the bearing mandrel shown in Figure 2 to press

bearing (18) into the housing to a required

depth of .290/.310 inches (7.37/7,87 mm) from

the outside end of the bearing counterbore.

SEE FIGURE 36B.

Figure 35 seal kit

Figure 36A

Figure 36B

Torqmotor™ Assembly

3

19

16

15

14

4