HY13-1526-001-M1/US

Torqmotor™ Service Procedure

TC, TS, TB, TE and TJ Series

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 US

36

NOTE

NOTE: Bearing mandrel must be pressed against the lettered end of bearing shell.

Take care that the housing bore is square with the press base and the bearing/

bushing is not cocked when pressing a bearing/bushing into the housing.

CAUTION

CAUTION: If the bearing mandrel specified in the “Tools and Materials Required

for Servicing” section is not available and alternate methods are used to press

in bearing/bushing (11) and (18) the bearing/bushing depths specified must be

achieved to insure adequate bearing support and correct relationship to adjacent

components when assembled.

CAUTION

CAUTION: Because the bearing/bushings (11) and (18) have a press fit into the

housing they must be discarded when removed. They must not be reused.

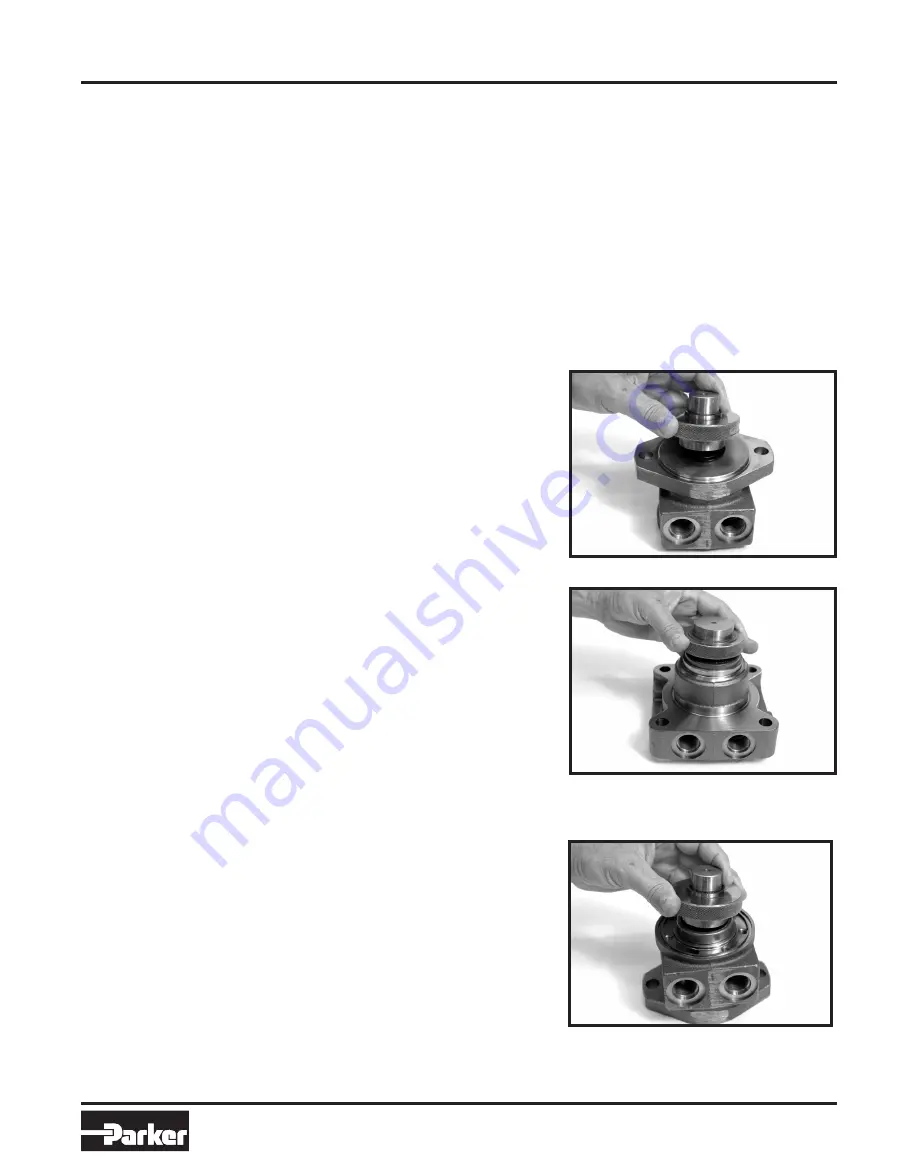

Figure 37A

Figure 37B

Torqmotor™ Assembly

Press in dirt &

water seal

2. Press a

new

dirt and water seal (19) into the

housing (17) outer bearing counterbore.

The dirt and water seal (19) must be

pressed in until its’ flange is flush against

the housing. SEE FIGURE 37A.

The TJ series dirt and water seal (19) must

be pressed in the lip facing out and until the

seal is flush to .020 inches (.51 mm) below

the end housing. SEE FIGURE 37B.

Figure 38

Press in inner

bearing/bushing

3. The inner housing bearing/bushing (11)

can now be pressed into its counterbore

in housing (17) flush to .03 inch (.76 mm)

below the housing wear plate contact face.

Use the opposite end of the bearing man-

drel that was used to press in the outer

bearing/bushing (18). Reference Figure 1,

“Tools and Materials Required for Servicing”

section. SEE FIGURE 38.