HY13-1526-001-M1/US

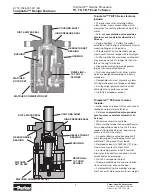

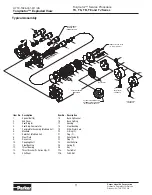

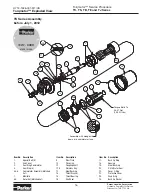

Torqmotor™ Service Procedure

TC, TS, TB, TE and TJ Series

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 US

8

Troubleshooting Checklist

1. Hose fittings loose, worn or

damaged.

2. Oil seal rings (3) deteriorated by

excess heat.

3. Special bolt (1, 1A, 1B or 1C)

loose or its sealing area

deteriorated by corrosion.

4. Internal shaft seal (14) worn or

damaged.

5. Worn coupling shaft (10) and

internal seal (14).

Oil Leakage

Check & replace damaged

fittings or “O” Rings. Torque to

manufacturers specifications.

Replace oil seal rings by disassembling

Torqmotor™ unit.

(a) Loosen then tighten single bolt to

torque specification.

(b) Replace bolt.

Replace seal. Disassembly of Torqmotor™

unit necessary.

Replace coupling shaft and seal by

disassembling Torqmotor™ unit.

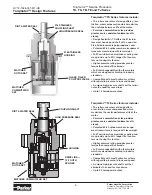

Significant loss of

speed under load

1. Lack of sufficient oil supply

2. High internal motor leakage

3. Severely worn or damaged

internal splines.

4. Excessive heat.

(a) Check for faulty relief valve and

adjust or replace as required.

(b) Check for and repair worn pump.

(c) Check for and use correct oil for

temperature of operation.

Replace worn rotor set by disassembling

Torqmotor™ unit.

Replace rotor set, drive link and coupling

shaft by disassembling Torqmotor™ unit.

Locate excessive heat source (usually a

restriction) in the system and correct the

condition.

Low mechanical

efficiency or

undue high pressure

required to operate

Torqmotor™ unit

1. Line blockage

2. Internal interference

3. Lack of pumping pressure

4. Excessive binding or loading in

system external to Torqmotor™

unit.

Locate blockage source and repair or

replace.

Disassemble Torqmotor™ unit, identify and

remedy cause and repair, replacing parts

as necessary.

Check for and repair worn pump.

Locate source and eliminate cause.

CAUTION: If the hydraulic system fluid becomes overheated [in excess of 200°F (93.3°C)], seals in the

system can shrink, harden or crack, thus losing their sealing ability.

Trouble

Cause

Remedy