Service/Spare Parts Manual

Series V16

MSG30-5526-M1/UK

13

Parker Hannifin

Pump & Motor Division Europe

Trollhättan, Sweden

Parker Hannifin

Pump & Motor Division Europe

Trollhättan, Sweden

Drain ports

There are two drain ports on the V16; the uppermost

drain port should always be utilized (fig. 3).

In order to avoid excessively high case pressure, the

drain line should be connected directly to the reservoir.

Note:

When the motor is operating, the case must be

filled with fluid to at least 50 %.

Hydraulic fluids

Ratings and performance data for series V16 motors

are valid when a good quality, contamination-free, pet-

roleum-based fluid is used in the hydraulic system.

Hydraulic fluids type HLP (DIN 51524), automatic trans-

mission fluids type A, or API CD engine oils can be used.

Fire resistant fluids, when used under modified opera-

ting conditions, and synthetic fluids are also suitable.

When the hydraulic system has reached full operating

temperature, the motor drain oil viscosity should be

above 8 mm²/s (cSt).

At start-up, the viscosity should not exceed 1500 mm²/s.

The ideal operating range for the V16 series is 15 to 30

mm²/s.

The following information (available from Parker Han-

nifin, Pump & Motor Division Europe) provide additional

information about:

- Hydraulic fluid specifications

- Fire resistant fluids

Before start-up

Make sure the motor case as well as the entire hydrau-

lic system is filled with hydraulic fluid. The internal lea-

kage, especially at low operating pressures, is not suf-

ficient to provide lubrication at start-up.

Note:

A drain line spring loaded check valve (shown

in fig. 2, 3 and 4) may have to be installed in or-

der to prevent oil from being siphoned out of the

motor case. This can otherwise happen e.g. if

the reservoir is located below the utilized motor

drain port.

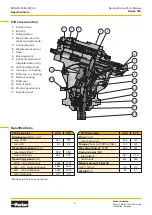

Fig. 2

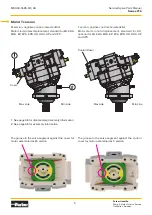

Fig. 3

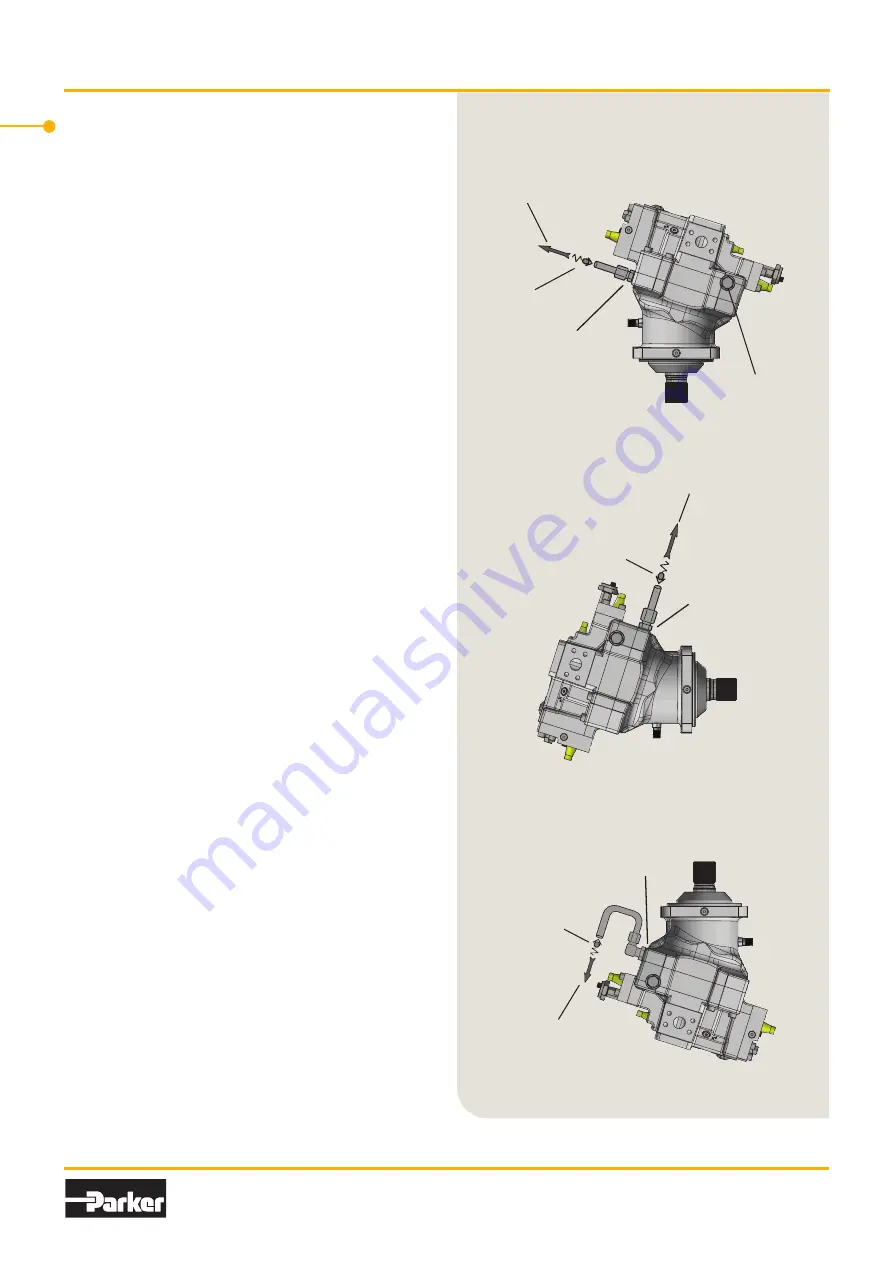

Fig. 4

Installation

Drain port

To reservoir

Check

valve

To reservoir

Check valve

Drain port

Drain and

cooling flow

to reservoir

Flushing valve

(optional)

Check

valve

Drain port