Service/Spare Parts Manual

Series V16

MSG30-5526-M1/UK

19

Parker Hannifin

Pump & Motor Division Europe

Trollhättan, Sweden

Parker Hannifin

Pump & Motor Division Europe

Trollhättan, Sweden

Gauge ports HO and HP

Threshold pressure setting procedure

HO/HP with negative control characteristics (M code)

With X5 not pressurized (HO/HP), the motor will be kept

at maximum displacement.

1. Make sure that the motor has been supplied with the

correct modulating spring (ordering code and name

plate information should agree). The hydraulic oil

should be 50°C.

2. Install a 0 – 600 bar gauge in port X1.

3. Turn the adjustment screw counter clockwise to en-

sure that the threshold spring is unloaded.

4. Pressurize port X5 to desired threshold pressure

(at this pressure the control starts to go to min. dis-

placement). Standard factory setting is 10 bar for

motors without displacement limiter on maximum

side.

5. Start turn the threshold adjustment screw clockwi-

se until the pressure gauge in port X1 starts to de-

crease. Right threshold current has been reached.

HO/HP with positive control characteristics (T code)

With X5 not pressurized (HO/HP), the motor will be kept

at minimum displacement.

1. Make sure that the motor has been supplied with the

correct modulating spring (ordering code and name

plate information should agree). The hydraulic oil

should be 50°C.

2. Install a 0 – 600 bar gauge in port X1.

3. Turn the adjustment screw counterclockwise to en-

sure that the threshold spring is unloaded.

4. Pressurize port X5 to desired threshold pressure (at

this pressure the control starts to go to max. dis-

placement). Standard factory setting is 10 bar for

motors without displacement limiter on minimum

side.

5. Start turn the threshold adjustment screw clockwi-

se until the pressure gauge in port X1 starts to de-

crease. Right threshold current has been reached.

Note:

One turn of the setting screw corresponds to:

•2.1 bar (30 psi) on HO and HP controls

WARNING

In order to prevent injury to the technician or the

bystanders during the adjustment procedure, all

hydraulic functions on the vehicle/machine should

be disabled (e.g. wheels raised off the ground,

work functions disconnected).

Avoid fast forward/reversed changes that can

damage the synchronizing shaft.

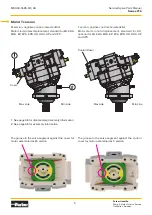

Controls and gauge ports

Main port A

Main port A

Port X2

Port X5

Airbleed

port

Port X1

Port X4

Port locations – V16 - 220/270 with HO control.

Gauge/pilot ports (HO control):

X1

Setting piston pressure

(large setting piston area)

X2

Servo supply pressure (after orifice)

X4

Servo supply pressure (before orifice)

X5

External pilot pressure (max 100 bar;

HO and HP control)

Port sizes:

–

M14x1.5 (ISO version)

–

9

/

16

"-18 O-ring boss (SAE version)

Setting screw