Variable displacement pump

Series VP1-095 / -110

/

-130

Bulletin MSG30-8214-INST/UK

Installation information

2

Parker Hannifin

Pump & Motor Division Europe

Trollhättan, Sweden

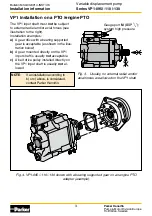

Inlet (suc-

tion) port;

the suction

fitting must

be ordered

separately

(see pg. 7)

Outlet (pressure)

port (BSP 1”)

Arrow indicates

pump rotation

(right hand

shown)

Fig. 1. VP1-095 / -110 / -130 main ports;

right hand rotating pump.

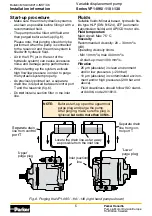

Fig. 2. VP1-095 / -110/ -130 main ports; left

hand rotating pump.

Inlet (suction) port;

the suction fitting

must be ordered

separately (see

pg. 7)

Outlet

(pressure)

port

(BSP 1”)

Arrow indicates

pump rota-

tion (left hand

shown)

Port T

(BSP ¼”)

2 x M12

depth 17

to attach

support

device

2 x M12

depth 17

to attach

support

device

Important installation

information

1

. Make sure max input torque and max

bending moment of the PTO (including

the VP1 pump) are not exceeded.

Also, make sure the direction of rotation

of the VP1 pump correspond to the PTO,

and that pump and PTO specifications

are not exceeded in the application.

2

. When VP1-095, -110 and -130 is as-

sembled to an engine PTO make sure

that the pump isn’t overheated in the

off-load mode. For more information, see

page 4, BPV-VP1 unloading valve.

3

. Never use excessive force when install-

ing a gear, coupling or sleeve on the VP1

pump shaft.

4

. The pump should be installed below the

lowest oil level in the reservoir (fig. 6, pg.

5);

if this is not possible, please contact

Parker Hannifin for further information.

5

. A separate drain line must be installed

between the control drain port T and the

reservoir (refer to fig. 6, pg. 5); connect

the drain line directly to the oil cooler (if

the hydraulic system is so equipped).

6

. A pressure relief valve is recommended

in the outlet (pressure) line from the

pump; it should be set 15–20 bar higher

than max pressure setting of the pump.

Example: The main pressure relief

valve located in the direc-

tional control valve.

Port T

(BSP ¼”)

NOTE:

- The suction fitting must be orde-

red separately (refer to

pg. 7

)

-

VP1-095 / -110 / -130 installation

on a PTO: please refer to page 3

for information.

NOTE:

Always run a function,

after adjusting the standby pres-

sure or the max pressure setting,

before you read the value.