Summary of Contents for PF6000X

Page 1: ...PF6000X Automatic Barrier Rev 1 0 Installation Operation Maintenance Manual ...

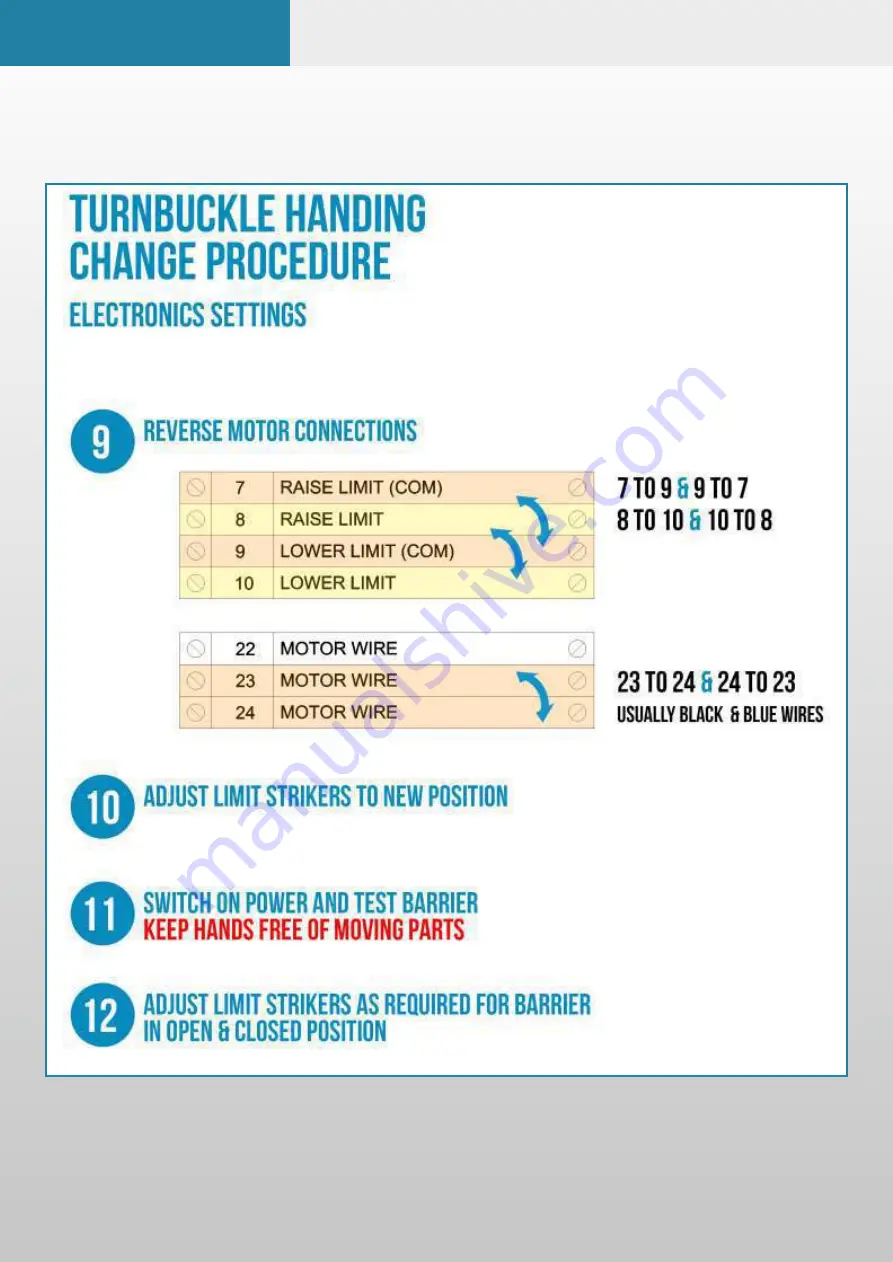

Page 11: ...PF6000X Handing Change Procedure ...

Page 12: ...PF6000X Handing Change Procedure ...

Page 13: ...PF6000X Handing Change Procedure ...

Page 14: ...PF6000X Barrier Manual Release Procedure ...

Page 15: ...PF6000X Straining Wire Assembly ...

Page 23: ...PF6000X Loop Detector Guide Relay Functionality Diagnostics ...

Page 28: ...PF6000X Safety Edge Setup ...

Page 29: ...PF6000X Safety Edge Setup ...