PF6000X

Troubleshooting Guide

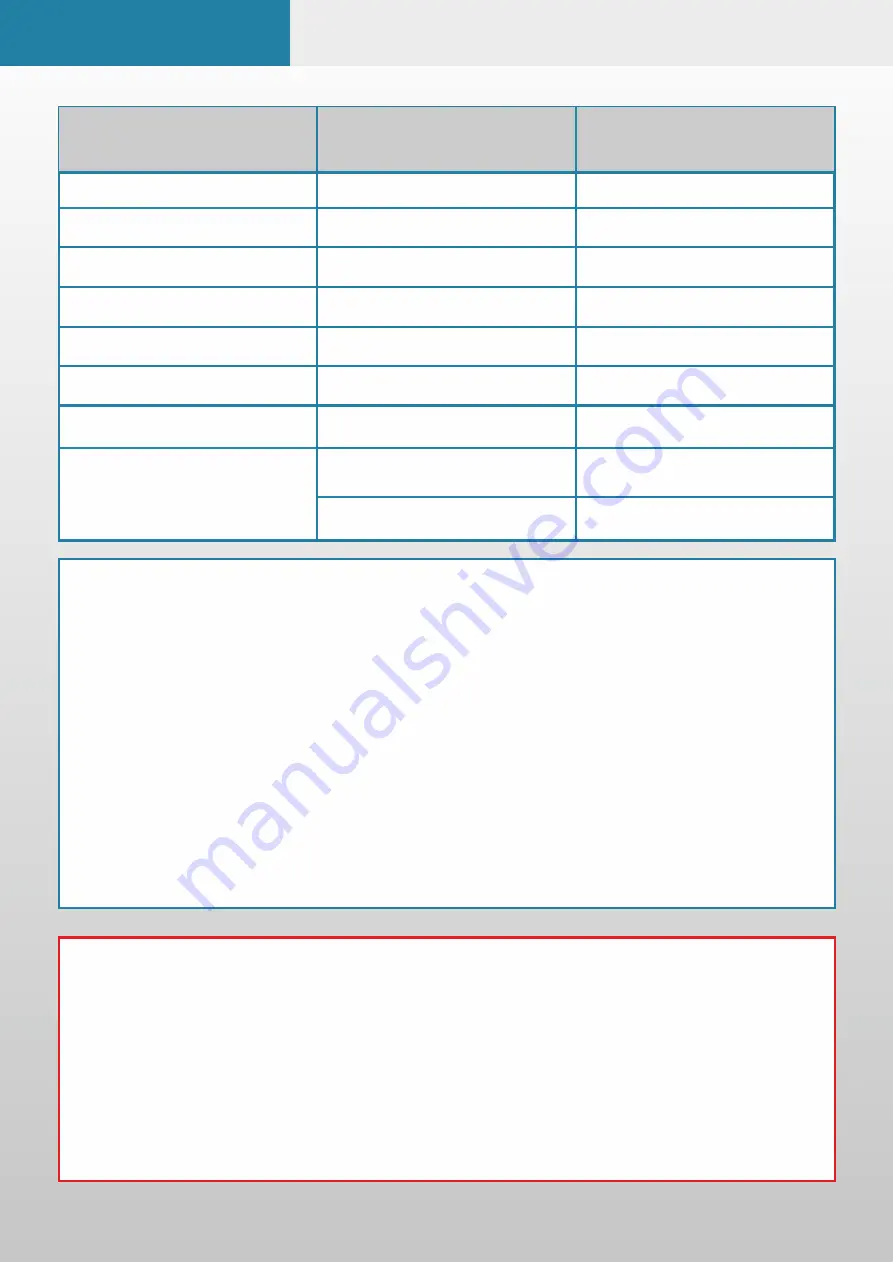

Barrier arm keeps going up and down

Limit switch fault

check and reset limit switches

Barrier creaking when moving

Check turn buckle

Oil or grease turn buckle

Barrier motor not running

Loss of voltage

Check motor supply test 3 phases

Barrier not raising or lowering

Drive shaft connections

Re-connect any drive shaft connections

Barrier not raising or raising half way

Gearbox

Gears stripped due to overloading replace

Barrier raises slowly and lowers too fast

Lack of balance counter weight compensation

Fit counter weights

Barrier not running at all

Door has been left open or switch not pushed in

Close the door and issue a signal to open or

close

Barrier raised will not lower

Key switch is left in open position

Turn key switch to auto

Loop fault or loop detecting

Check if green light is on detector if so remove

object that it is detecting or replace loop

MECHANICAL ERRORS

CAUSE

CORRECTION

1. If the barrier has a permenant raise signal for over 2 minutes, the PLC display will show:

PERMANENT RAISE SIGNAL

2. If the Free Exit/Entry Loop Detector has a constant signal, the PLC display will show:

CHECK FREE EXIT LOOP DETECTOR

3. If the barrier has photocells or a safety edge connected and they are faulty, the PLC

display will show:

CHECK PHOTOCELLS / SAFETY EDGE

PLEASE NOTE THAT THE PHOTOCELLS AND OR SAFETY EDGE ON BARRIER ARE

ACTIVE FOR A FEW SCONDS OF THE BARRIER REACING THE LOWER LIMIT

SWITCH. THIS IS FOR SAFETY REASONS.

ATTENTION!

IT IS THE RESPONSIBILITY OF SITE TO DO THEIR OWN RISK ASSESSMENT TO

HIGHLIGHT THE RISKS ASSOCIATED WITH THE AUTOMATIC BARRIER FOR THEIR

SITE. SITE MANAGEMENT SHOULD ALSO ENSURE ANY OPERATORS OF THE

EQUIPMENT ARE TRAINED APPROPRIATELY.

WE ADVISE THAT EXTREME WEATHER CONDITIONS & HIGH WINDS ARE INCLUDED

IN A RISK ASSESSMENT. IT MAY BE NECESSARY FOR BARRIERS TO BE DISABLED

DURING EXTREME WEATHER CONDITIONS (IN THE DOWN POSITION, SECURED) OR

FOR THE POLE & ANY SKIRTING TO BE TEMPORARILY REMOVED

Summary of Contents for PF6000X

Page 1: ...PF6000X Automatic Barrier Rev 1 0 Installation Operation Maintenance Manual ...

Page 11: ...PF6000X Handing Change Procedure ...

Page 12: ...PF6000X Handing Change Procedure ...

Page 13: ...PF6000X Handing Change Procedure ...

Page 14: ...PF6000X Barrier Manual Release Procedure ...

Page 15: ...PF6000X Straining Wire Assembly ...

Page 23: ...PF6000X Loop Detector Guide Relay Functionality Diagnostics ...

Page 28: ...PF6000X Safety Edge Setup ...

Page 29: ...PF6000X Safety Edge Setup ...