Bolt Kit Contents

4x M20x

500mm

Threaded bar (per gate)

8x M20 Bolts (per gate)

8x M20 Penny washers (per gate)

1x Resin fix tube

2x resin fix nozzles

4x M16x100

mm

anchor bolts (for either catch post or center stop)

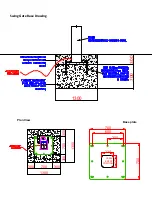

Swing Gate

Bolt Down Procedure

1.

You need to prepare the ground to accept the

swing gate

tower. you should consult

the

issued CAD

drawings. Be sure to CAT scan any area before excavation

2.

The

re are 2 different ways the gates are installed depending on what you order. The gate is installed

i

n

2 steps if it is “cast-in”

where the first pour is set below the ground level and the gate is bolted down

then a second pour is done up to the ground level. Please note! if the gate is being installed in an area

with a high water table you need to ensure you have adequate drainage. I

f you have opted for a “bolt-

down” installation

then

it would just be 1 step where it is just bolted down to the plinth at ground level.

3.

the first pour

of concrete (mentioned above) this should be 700mm deep. When this has cured you

drill and chem fix

4

x M20

threaded bars

into the surface to line up with the fixing holes in the gate

tower

base plate, (these have a nut above

and below the tower base

plate for adjustment/alignment

purposes).

4.

The gate leaf & tower will be

lowered

(base plate first) onto the threaded bar. here it will secured and

leveled up in all

direction

s

ensuring that the tower sits up out of the hole to the correct (level) height.

This is a very

important step as when the

other gate is fitted. It will need to line up with the

secondary

leaf

or catch post depending on the order

. Please note that this is very important

as there is only a

MINIMAL adjustment once the gates

receive the second pour of concrete.

5.

Once

the gate has now been

lowered

onto the threaded bar and has been leveled

accordingly

the

duct

can be pushed through the hole in the gate tower

if it is cast in

.

If it is a bolt down then this would

be

through the center of the base plate.

6.

Once the duct has been fed through the duct hole the second pour can be made

(cast in only)

. You

must allow for ducting to link one tower to the other

or to the catch post

as you

have to have a

communication

s

cable to allow the Master/Slave function

and the photocells

.

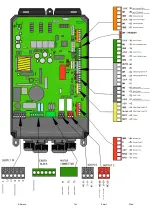

Summary of Contents for PF9700

Page 13: ...Address Tel Email Web Engineers Sec on Not For End Users Control Panel Overview...

Page 20: ...Address Tel Email Web...

Page 21: ...Address Tel Email Web...

Page 22: ...Address Tel Email Web...

Page 23: ...Address Tel Email Web...

Page 24: ...Address Tel Email Web...

Page 25: ...Address Tel Email Web...

Page 26: ...Address Tel Email Web...

Page 27: ...Address Tel Email Web 24v From External PSU Switch to Drop Bolt...