Address:

Tel:

Email:

Web:

Parameter Function

Parameter

Display Adj. Range

Factory

Setting

Loop Detector Parameters

20 to 29

P.660

22

20: Deactivated

21: Evaluation only for command forwarding

22: Open command

23: Safety during closing with reversing

24: Safety during closing with stop

25: Verifies a suitably programmed external open command to act as safety check and also safety during closing

27: Safety during opening and closing, after releasing during opening continues to open

Loop detector channel 1

28: Safety during opening and closing, after releasing during opening continues to open, close after fully open

29: Gives leginimation for external open commends programmed accordingly

20: Deactivated

21: Evaluation only for command forwarding

0 to 7

P.664

0

0: Without auto close time

1: With auto close time (P.010)

2: With auto close time (P.015)

3: Without auto close time, other auto close times blocked for other open commands

4: Auto close time as used before with last open command

5:Auto close time is stopped after activating in the open position and will go on after deactivation

6: With priority 1

Auto close time channel 1

7: With priority 2

0

0: Without auto close time

1: With auto close time (P.010)

2: With auto close time (P.015)

3: Without auto close time, other auto close times blocked for other open commands

4: Auto close time as used before with last open command

0

P.670

20 to 29

23

22: Open command

23: Safety during closing with reversing

24: Safety during closing with stop

25: Verifies a suitably programmed external open command to act as safety check and also safety during closing

27: Safety during opening and closing, after releasing during opening continues to open

28: Safety during opening and closing, after releasing during opening continues to open, close after fully open

0: No close command

1: Close command only if triggered after open limit is reached

2: Close command after open limit is reached (command stored whilst opening)

3: Close command after safety released, also when opening

P.66C

0 to 3

Close command after detector channel 1

Loop detector channel 2

More options avaliable, check pages 196-197 of the Feig Parameter Description Total Overview manual

0

0: No close command

1: Close command only if triggered after open limit is reached

2: Close command after open limit is reached (command stored whilst opening)

3: Close command after safety released, also when opening

5:Auto close time is stopped after activating in the open position and will go on after deactivation

6: With priority 1

7: With priority 2

P.67C

0 to 3

Close command after detector channel 2

29: Gives leginimation for external open commends programmed accordingly

P.674

0 to 7

Auto close time channel 2

0000: Deactivated

0101: TST SURA1 safety edge card fitted (1 8k2 input)

0106: TST SURA6 safety edge card fitted (6 8k2 inputs)

0302: Loop card fitted (single or dual channel)

P.802

0000

to

0302

0302

Plug in card options

Output 1 and 2 profiles

0001: Output is perminently on

0101: Output activates in the open position

0201: Output activates in the closed position

0401: Output active whilst there are no faults showing on the controller

0801: Output is active during opening and closing operations

1101: Maglock receives voltage when in the closed position

1201: Traffic light on the inside of site

1210: Traffic light on the outside of site

12A1: Traffic light without direction, Flashing during close delay timer (P.025)

Accessory Parameters

Output Parameters

0000

to

3201

P.701

P.702

P.70F

0101

0201

0801

Summary of Contents for PF9700

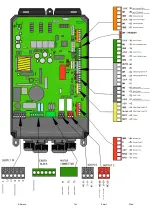

Page 13: ...Address Tel Email Web Engineers Sec on Not For End Users Control Panel Overview...

Page 20: ...Address Tel Email Web...

Page 21: ...Address Tel Email Web...

Page 22: ...Address Tel Email Web...

Page 23: ...Address Tel Email Web...

Page 24: ...Address Tel Email Web...

Page 25: ...Address Tel Email Web...

Page 26: ...Address Tel Email Web...

Page 27: ...Address Tel Email Web 24v From External PSU Switch to Drop Bolt...