PRESSURE TESTING

1

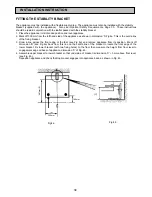

The rapid injector is used as a pressure test point.

2.

Connect the pressure gauge to the Rapid injector.

3.

Check the supply pressure by turning the Rapid burner on and one other hotplate burner full on and light the

appropriate burner. The pressure should be either:-

(i) For Natural Gas 20mbar

(ii) For LP.Gas. The pressure must be set to 28 mbar for use on butane or 37 mbar for use on propane.

4.

Turn off the taps, disconnect the pressure gauge.

5.

Check operation of each hotplate burner.

CHECKING THE GRILL

Place the grill pan containing the grid and with the handle attached into the grill compartment. Open the grill door

and turn the grill control to full on. Visually check that both elements are heating up.

CHECKING THE HOTPLATE

Lift the lid. Fit the burner crowns and caps ensuring that they are correctly seated. Fit the pan supports. Check

each of the hotplate burners in turn by turning the hotplate tap to its full on position and pushing the ignition button.

As soon as the burners are lit the button can be released.

CHECKING LID SHUT-OFF DEVICE

1. Lift the lid.

2.

Turn one hotplate burner tap to its full on position and push the ignition button.

3.

Close lid. There should now be no gas supply to the hotplate and the burner will go out.

4. Turn off the hotplate tap and lift the lid. The gas supply should now be restored to the hotplate, when the tap is

turned on.

CHECKING THE MAIN OVEN

1. Turn on the main oven thermostat to the highest setting.

2. Ensure the oven is heating up by checking first that the oven neon illuminates.

3. After a short period the heat from the oven element may be felt with the oven door open.

4. Check that the oven lights and the oven fan are functioning.

CHECKING THE SECOND OVEN

1. Ensure that the oven door is closed.

2. Turn on the second oven thermostat to the highest setting.

3. Ensure that the oven is heating up by checking firstly that the oven neon illuminates.

4. After a short period the heat from the oven element may be felt with the oven door open.

5. Check that the oven light is functioning.

35

INSTALLATION INSTRUCTION