Page 18

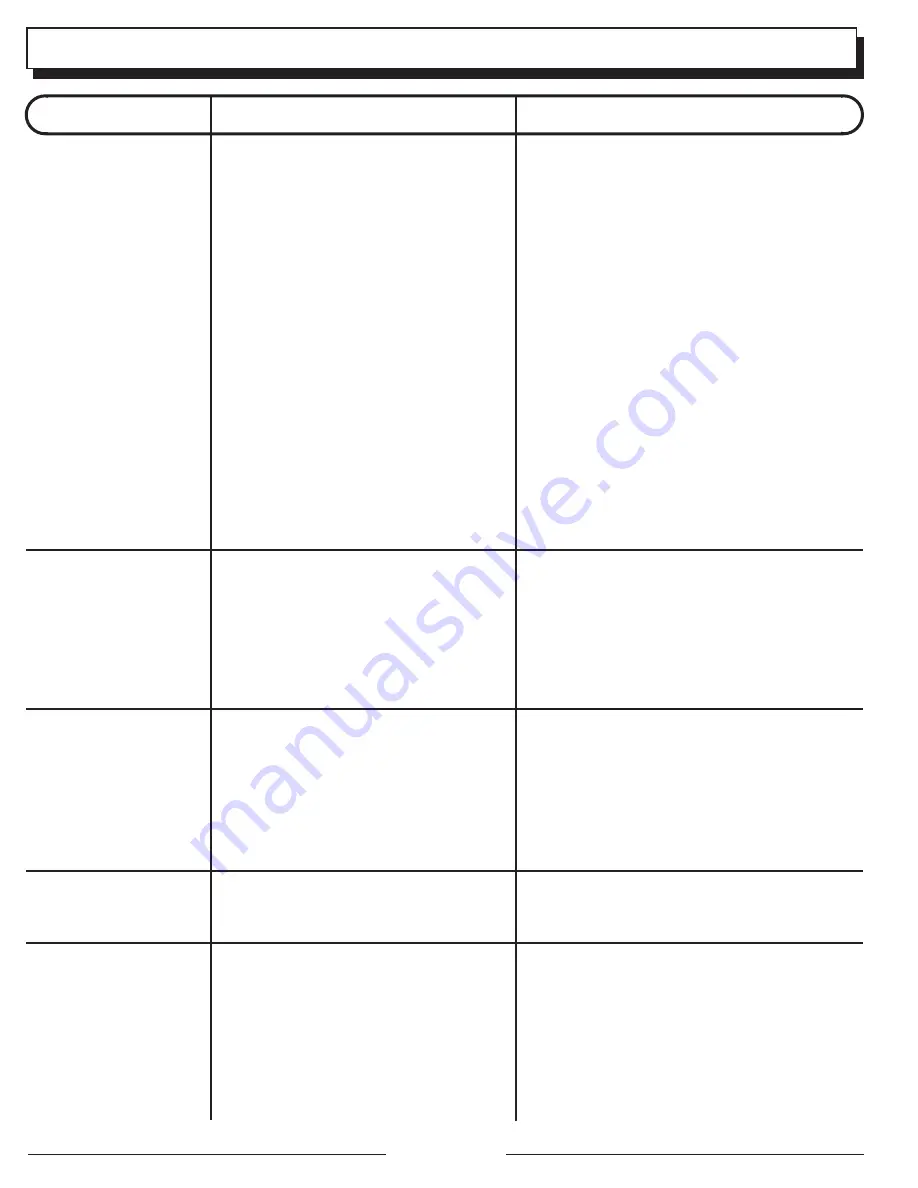

TROUBLESHOOTING

Problem

Possible Cause

Solution

Engine does not start

Spark plug wire disconnected

Engine not primed

Defective or incorrectly gapped spark plug

Fuel tank empty or low

Dirty carburetor or fuel line

Carburetor dirty

Engine flooded

Throttle control lever in incorrect position

Stale gasoline

Defective throttle control lever or wire

Dirty air filter

Connect spark plug.

Prime engine.

Inspect or replace spark plug.

Add fuel.

Clean carburetor or fuel line.

For carburetor cleaning, take the unit to an

Authorized Service Center.

Wait several minutes before starting.

Move throttle lever to FAST or START position.

Drain old gasoline and add fresh gasoline.

Inspect lever and wire. Replace if damaged or defective.

Replace air filter.

Engine runs poorly

Bad spark plug

Dirty air filter

Carburetor out of adjustment

Stale gasoline

Replace spark plug.

Replace air filter.

Adjust carburetor. Take the unit to an authorized

Service Center.

Drain old gasoline and add fresh gasoline.

Engine overheats

Engine cooling system clogged

Engine cooling system clogged

Carburetor out of adjustment

Oil level is low.

Clean engine screen and cooling fins.

Clean debris system and engine cooling fins.

Adjust carburetor. Take the unit to an authorized

Service Center.

Add oil.

Engine will not stop

running

Defective throttle control lever or wire.

Throttle not adjusted properly.

Inspect and replace damaged parts.

Move throttle to the full OFF position.

Poor trimming

performance

Trimmer line length is too short

Engine not set at FAST speed

Correct line length is 21.5 inches. When less

than 1/2 this length, replace the line.

Move engine throttle lever to FAST position.