14

Adjustments

H

Operation

(Continued)

• Save all instructions

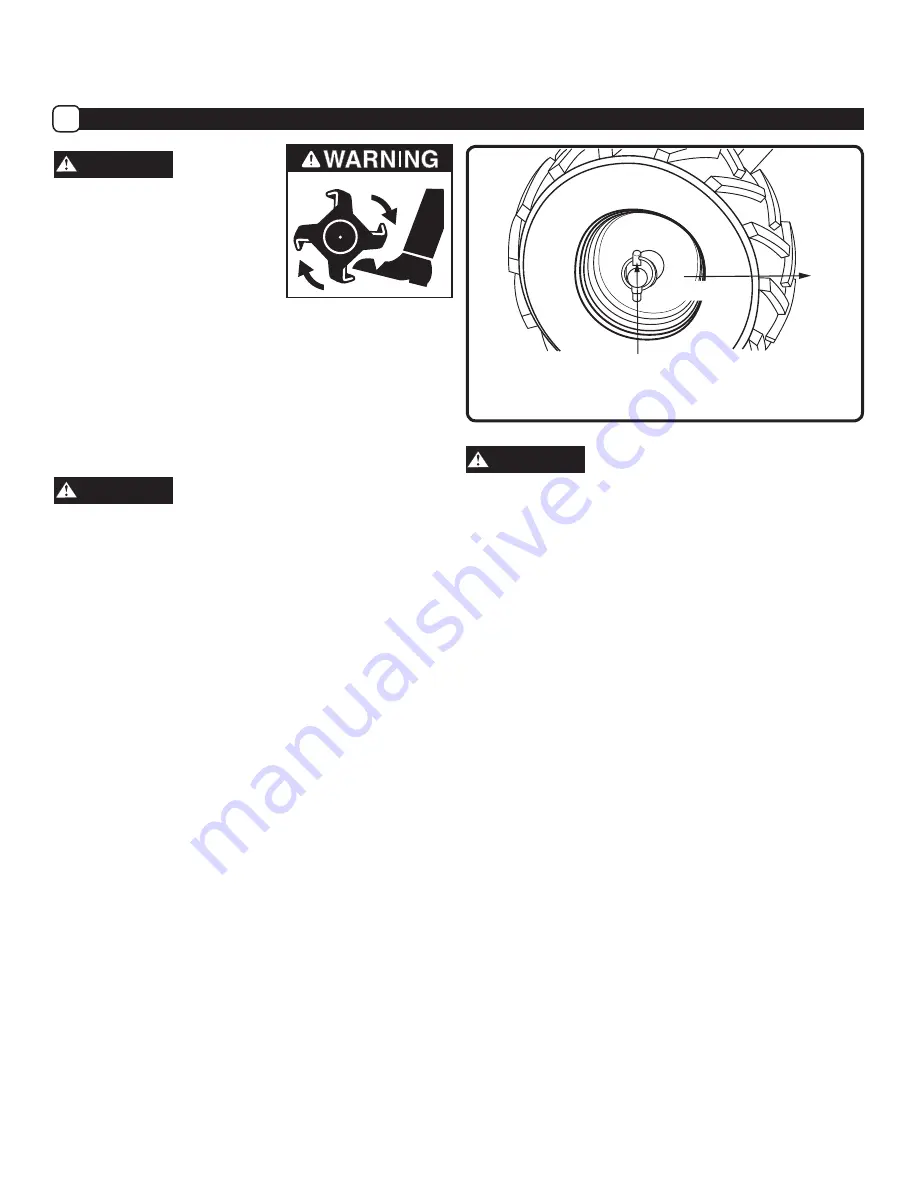

WHEEL LOCK PINS

(See Figures 2 and 11)

Place wheels in tilling position.

1. Remove lock pin. Align hole in axle with hole in wheel hub.

2. Insert lock pin through holes, fold lock pin ring to secure

pin to axle.

3. Firmly lock wheel and axle together before tilling.

4. Repeat for other wheel.

WARNING

Always have both wheel lock pins in or out. Do not operate

tiller with only one wheel locked.

To place wheels in free-wheel position.

1. Remove lock pin. Slide wheel inward toward machine.

2. Insert pin in axle only, fold lock pin ring to secure pin to axle.

3. Wheel should turn freely on axle.

HANDLEBAR HEIGHT ADJUSTMENT

(See Figure 4)

Adjust handlebar height.

The ideal height of the handlebar varies with operator

height and the depth of tilling. To adjust handlebar height:

1. Unscrew nuts and remove top bolts on each side.

2. Loosen the lower bolts. Do not remove.

3. Align handlebar to desired holes on the lower handlebar

mount.

4. Install bolts and nuts. Retighten all four bolts securely.

DEPTH REGULATOR LEVER

(See Figure 3)

Tilling depth is controlled by the height of the

depth regulator lever. To adjust tilling depth:

1. Remove pin.

2. Raise the depth regulator lever to position tines at

chosen tilling depth.

3. Align hole in depth regulator lever with hole in depth

regulator bracket and replace pin.

Depth Regulator Lever Down

= Shallower tilling.

Place the pin in the top hole of the depth regulator lever for

shallowest tilling.

Depth Regulator Lever Up

= Deeper tilling.

Place the pin in the bottom hole of the depth regulator lever

for deepest tilling.

WARNING

Engine should be off before ad-

justing any controls.

Extreme caution should be used

when operating tiller in the reverse

direction.

Wheel lock pin in free-wheel position

(axle holes only)

FRONT

Figure 11

WARNING

Do not adjust tilling depth unless drive safety control levers are

released to neutral position.

Always set the depth regulator lever in the transport posi-

tion before starting engine, that is, place the detent pin in

the highest hole of the depth regulator lever.