22

C)

The air intake needs to be between 25% - 50% open to obtain the best result for burning wood.

Warning!

–

This Appliance will be hot when in operation and due care should be taken.

We advise that suitable gloves, or the operating tool is used when operating the air control, and when opening the

door

.

Primary Air -

The primary air provides a conventional air draught to the bed of the fire.

Secondary Air -

The secondary air is the air control for the air wash that keeps a clean and uninterrupted view of

the fire.

Tertiary Air-

The tertiary air aids in good secondary combustion of the fuel and reducing emissions into the chimney

and environment.

BURNING WOOD

Lighting the Stove

First, load the fire with starting fuel, i.e. paper, dry sticks and/or firelighters. Light the fire at the base with the air

control fully open (B). Allow the fuel to reach a steady glow and build the fire up gradually. Once you have a good

fire established across the grate bed, further fuel can be added as required.

Reduced Combustion

To shut down the stove push the air control rod fully in (A). If the controls are left in this position, the fire will be

starved of air and will die down. If you want to revive the fire, pull the air control rod until it is fully open (B) then

push it in halfway for normal burning (C).

Warning!

- The stove will remain hot for a considerable time after the fire has been extinguished.

Notes on Woodburning

With a full load of wood, the stove will need to be refuelled approximately once every hour. Wood can be stacked in

the stove, but no higher than the tertiary air holes at the back of the firebox.

Overloading the stove can cause excess smoke to be emitted. Wood burns most efficiently with the air control

halfway open (C).

Wood burns most efficiently on a bed of ash and it is therefore only necessary to remove surplus ash from the stove

occasionally. Ash can be removed with the tool supplied.

If there is insufficient burning material in the fire bed to light a new fuel charge, excessive smoke emission can occur.

Refuelling must be carried out with a sufficient quantity of glowing embers and ash, so that the new fuel charge will

ignite quickly. If there are too few embers, add some kindling to prevent excessive smoke. After refuelling leave the

air control fully open for one minute before reducing to the desired setting.

(When refuelling it is important to have a damper in the open position if you have one.) If a damper is needed a full

size flue collar (CH05010) will need to be fitted.

Ensure your logs are well seasoned with a moisture content of less than 20%

Summary of Contents for ASPECT 14

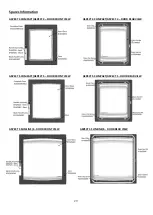

Page 13: ...13 Dimensions Aspect 6 Dimensions Aspect 7 Dimensions Aspect 8 Slimline ...

Page 14: ...14 Dimensions Aspect 8 Dimensions Aspect 9 Dimensions Aspect 14 ...

Page 31: ...31 BODY ASSEMBLY SPARES ASPECT COMPACT 5 AND 5 BODY ASSEMBLY SPARES ASPECT 5 SLIMLINE ...

Page 32: ...32 BODY ASSEMBLY SPARES ASPECT 6 BODY ASSEMBLY SPARES ASPECT 7 ...

Page 33: ...33 BODY ASSEMBLY SPARES ASPECT 8 BODY ASSEMBLY SPARES ASPECT 8 SLIMLINE ...

Page 34: ...34 BODY ASSEMBLY SPARES ASPECT 9 BODY ASSEMBLY SPARES ASPECT 14 ...